Dry cleaning method and dry cleaning equipment for slurry on inner wall of premixed concrete tank truck

A technology of ready-mixed concrete and concrete, applied in cleaning methods and appliances, chemical instruments and methods, comprehensive factory control, etc., can solve the problems of waste of resources, environment, pollution, difficult to handle, etc., to save building resources and solve secondary pollution Effect

Active Publication Date: 2022-05-31

NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Aiming at the above-mentioned deficiencies existing in the prior art, the present invention provides a dry-cleaning method and dry-cleaning equipment for the inner wall slurry of a ready-mixed concrete tank truck to solve the existing Secondary pollution such as alkaline waste water, pasty mortar, massive solids, etc. are generated during the cleaning process of existing technologies. The cleaned slurry and materials cannot be reused and are difficult to handle, resulting in a huge waste of resources and environmental pollution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

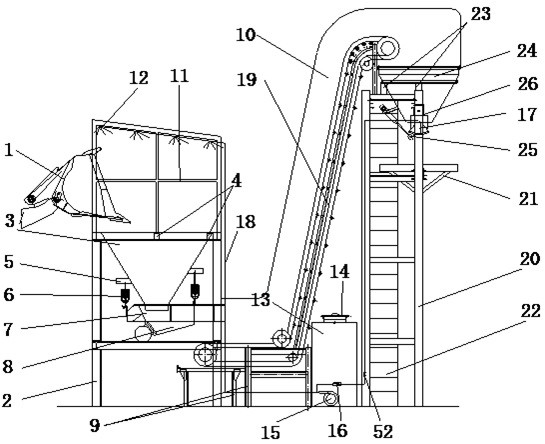

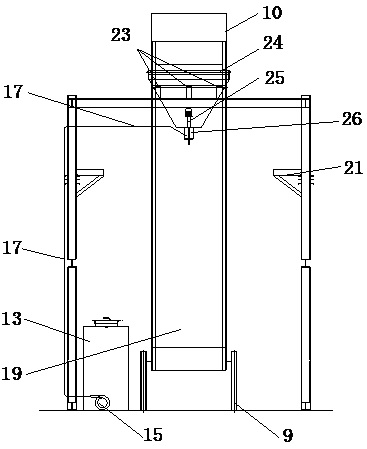

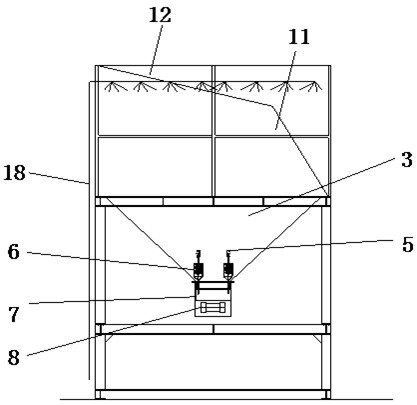

The invention relates to a dry cleaning method and dry cleaning equipment for slurry on the inner wall of a premixed concrete tank truck. The method comprises the following steps that (1) a debugging system is installed; 2) collecting local daily temperature within five years; 3) setting identification and weighing equipment; 4) determining the local day temperature; 5) determining a weight difference value and a time difference value of vehicles entering and exiting the station; 6) determining the weight of excess materials; 7) driving the vehicle to a heavy load induction acquisition area; (8) the water adding amount and the mass of the dry cleaning medium are determined; (9) controlling dry cleaning; the dry cleaning equipment comprises a material lifting system mounted on a lifting bracket, an unloading system connected with the material lifting system and used for feeding a dry cleaning medium into a mixing drum of the concrete tank truck, a waterway system used for controlling spraying dust removal, and a control system. According to the dry cleaning and recycling device, the problem of secondary pollution caused by cleaning of the slurry on the inner wall of the premixed concrete tank truck is practically and effectively solved, precious building resources can be economically and reasonably saved, and the dry cleaning and recycling device is an indispensable matched dry cleaning and recycling device for a concrete mixing plant.

Description

A kind of dry-cleaning method and dry-cleaning equipment for inner wall slurry of ready-mixed concrete tanker technical field The invention belongs to the concrete tank truck dry cleaning technical field, be specifically related to a kind of ready-mixed concrete tank truck inner wall slurry drying Washing methods and dry cleaning equipment. Background technique At present, the ready-mixed concrete industry also adopts high-pressure water flushing, shovel hammer for the cleaning of concrete tanker inner wall slurry. Cleaning methods such as knocking; secondary pollution such as alkaline waste water, paste-like mortar, and bulk solids are generated during the cleaning process. Slurry and materials cannot be reused and are difficult to handle, resulting in great waste of resources and environmental pollution. Therefore, a treatment method is required. The method and equipment are convenient, non-polluting, and low in cost, and can recycle residual materials. SUMMARY O...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B9/08B08B13/00

CPCB08B9/08B08B13/00Y02P90/02

Inventor 李海华何新生张建党王国峰刘莉莉孙震宇李克亮王新科申翔宇

Owner NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com