Cutting machine for building boards

A technology for building boards and cutting machines, applied in metal processing and other directions, can solve problems such as dumping of building boards, waste of building boards, and difficulty in cleaning, and achieve the effects of accelerating construction progress, scientific and reasonable structure, and safe and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

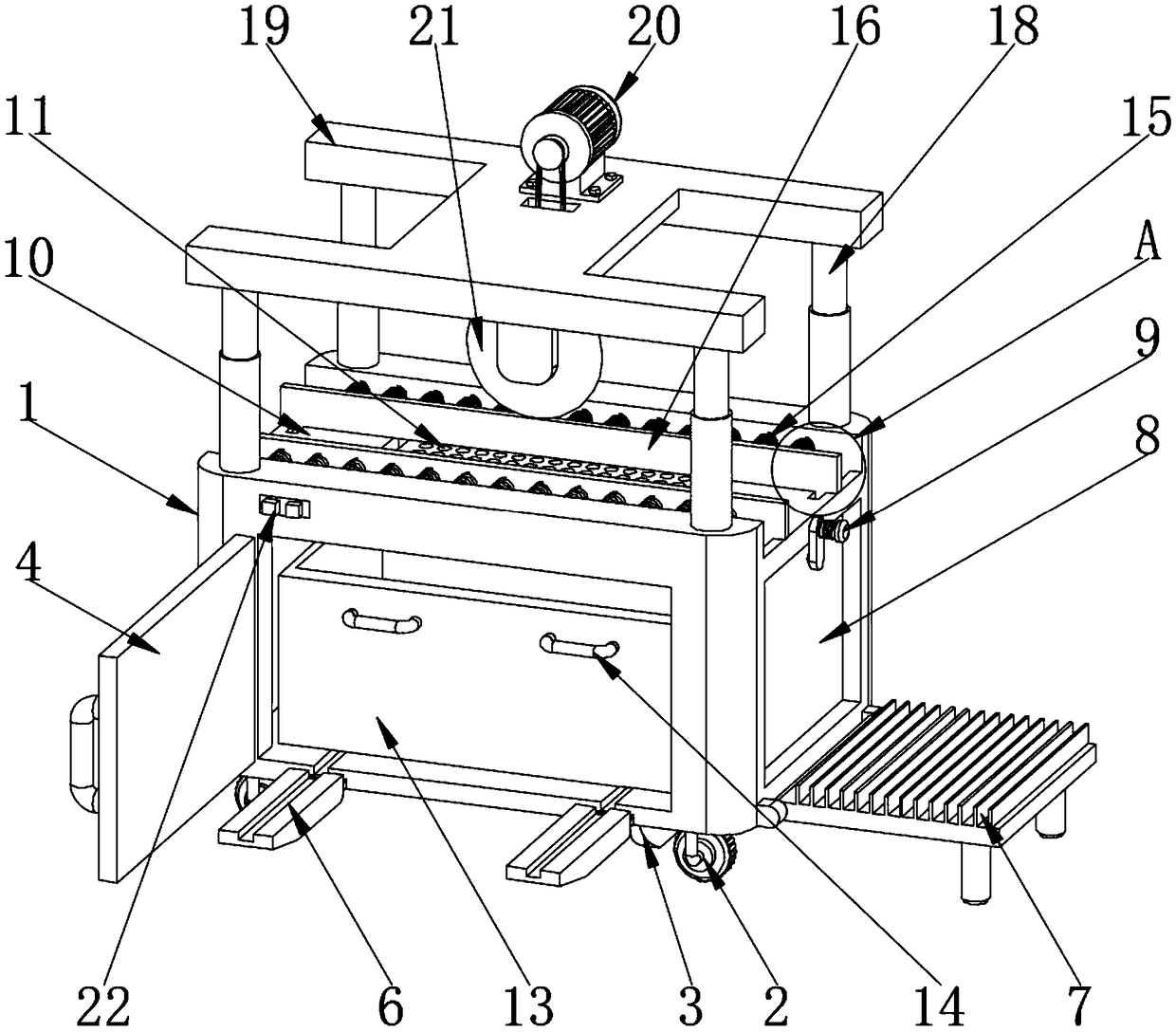

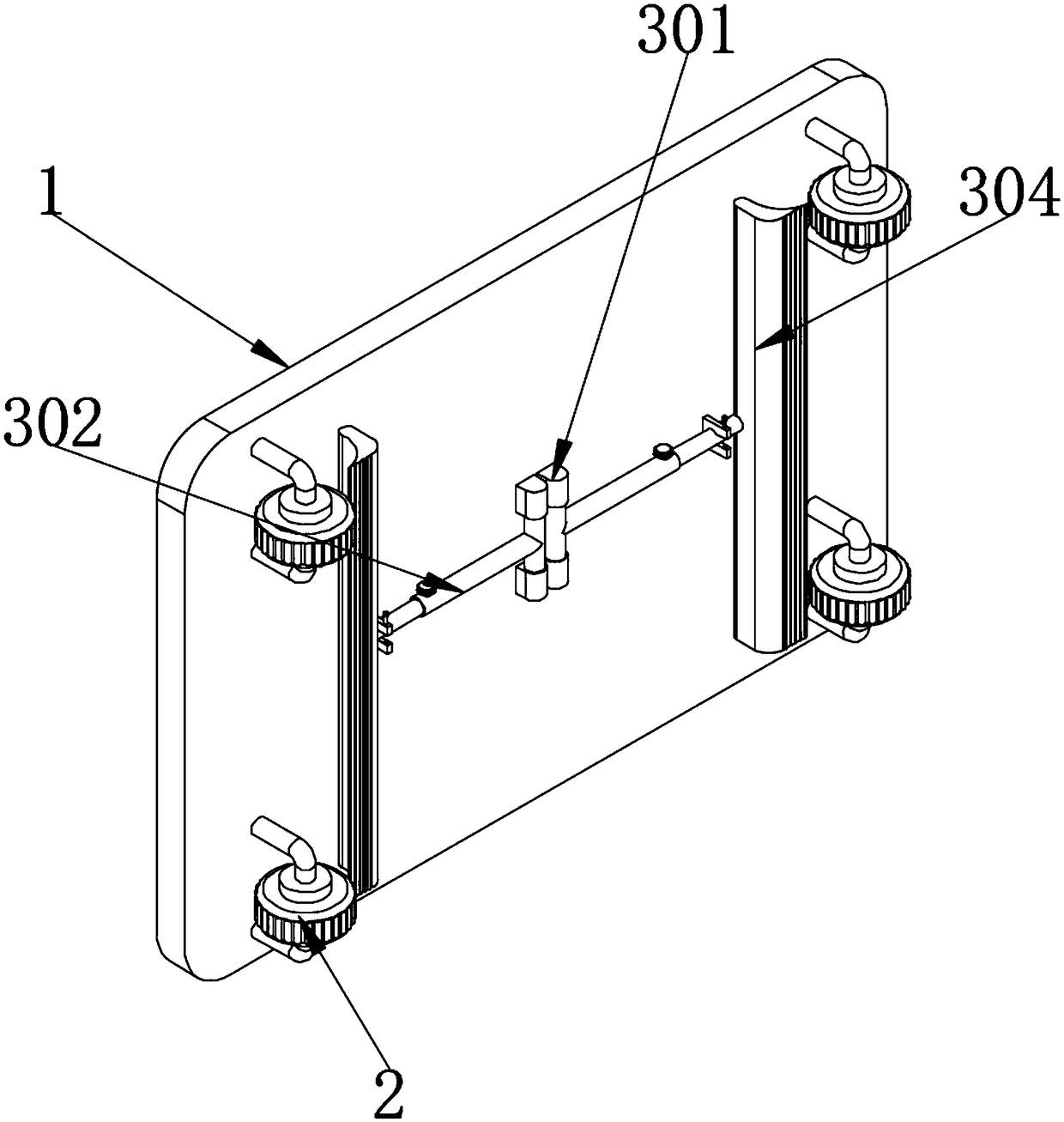

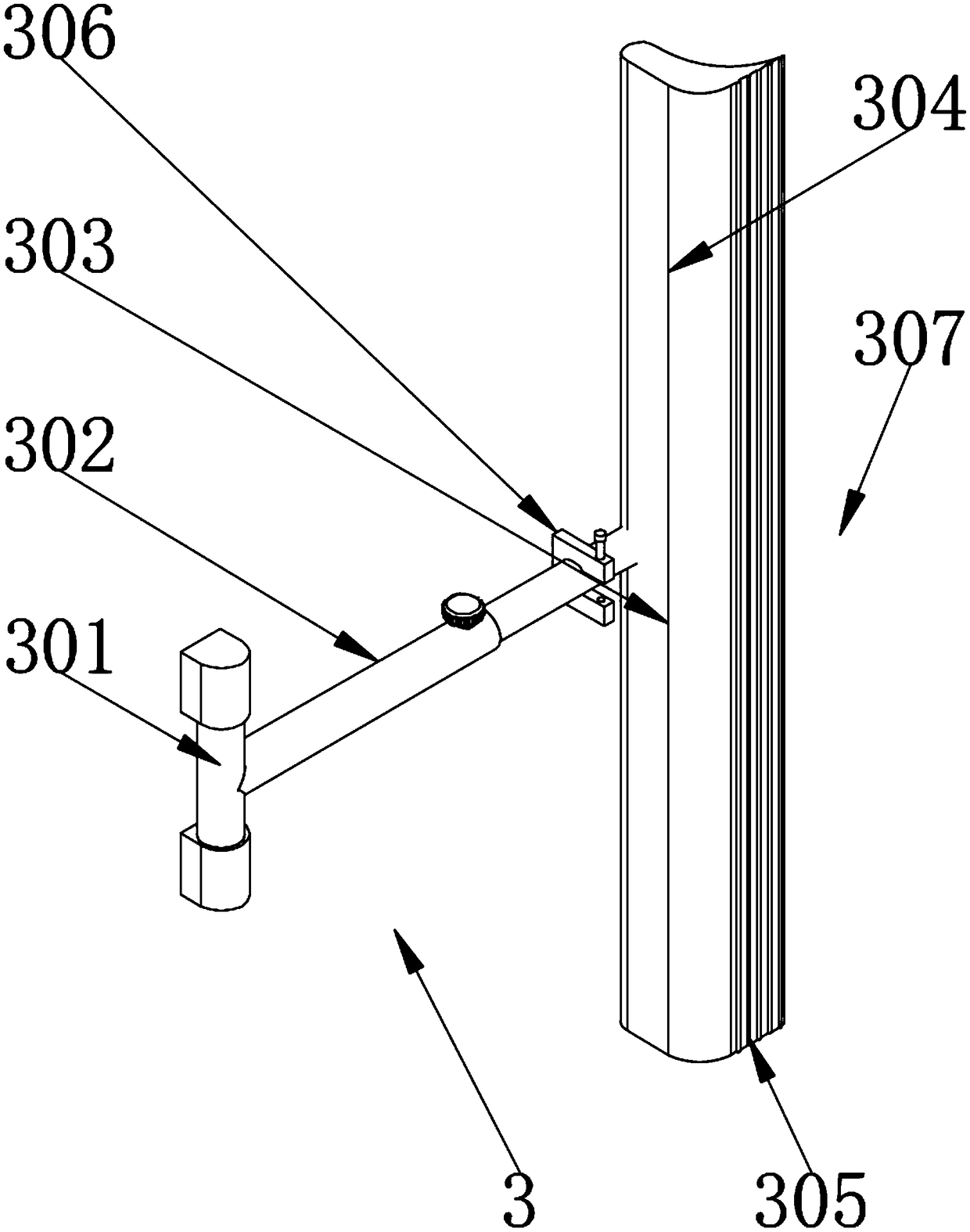

[0032] Example: such as Figure 1-7As shown, the present invention provides a technical solution, a cutting machine for building boards, including a box body 1, each top corner of the bottom end of the box body 1 is fixed with a moving wheel 2 by fixing screws, and the middle part of the bottom end of the box body 1 A stabilizing component 3 is installed, and the stabilizing component 3 includes a first rotating shaft 301, a manual lifting rod 302, an adjustment knob 303, a stable seat 304, an anti-skid pattern 305, a fixing plate 306 and a limit pin 307. The middle part of the first rotating shaft 301 is welded with a manual lifting rod 302, and the middle part of the manual lifting rod 302 is embedded with an adjusting knob 303. In order to prevent slipping during the process of rotating the adjusting knob 303, An anti-slip protrusion is installed on the outside of the adjustment knob 303, and one end of the manual lifting rod 302 is welded with a stable seat 304, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com