Cab with short and long head and wide view for mining

A wide field of view, cab technology, applied in the superstructure, superstructure, transportation and packaging of trucks, can solve the problems of narrow field of view, unfavorable driver safety, high cost of small batch production, etc., to increase safety performance , optimize the skeleton strength, the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

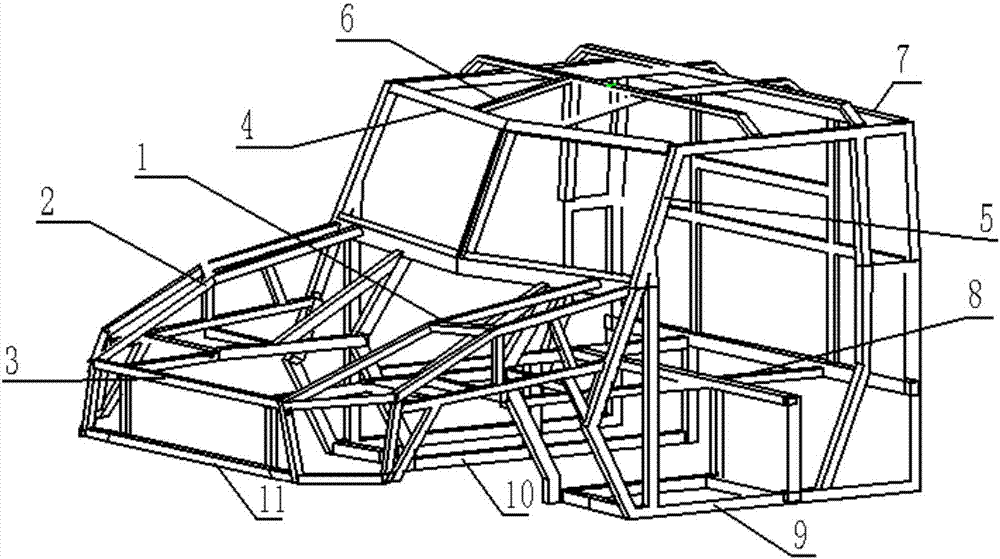

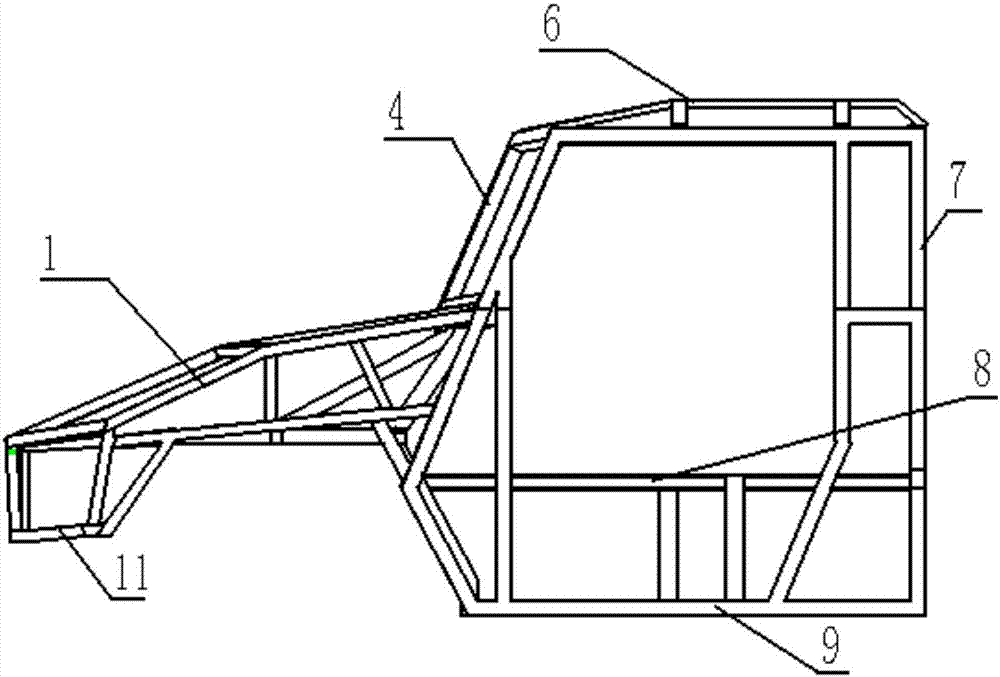

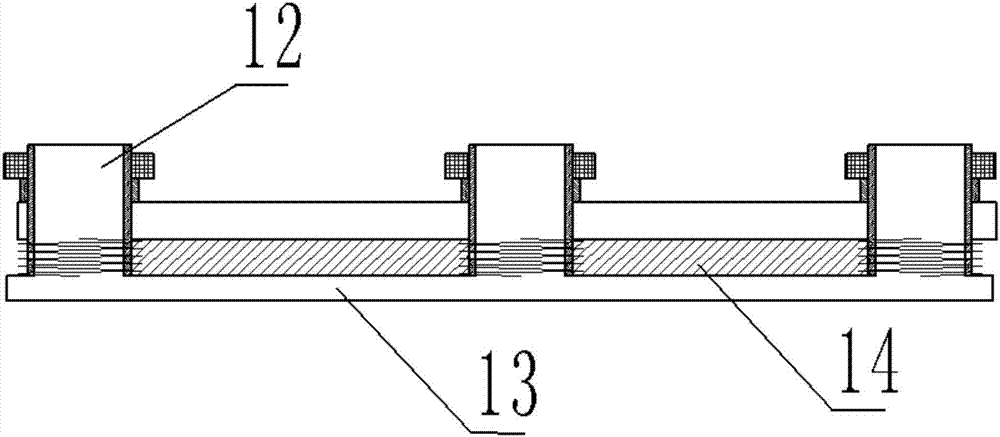

[0017] like Figure 1 to Figure 4 As shown, the mine-used short and long head cab with wide field of view of the present invention includes a right frame 1, a left frame 2, an anti-collision beam 3, a pointed nose window 4, a support beam 5, a top frame 6, a back frame 7, and a seat frame 8, right fixed frame 9, left fixed frame 10, anti-collision fixed frame 11, right frame 1, left frame 2 are respectively installed on the right side, left side of support beam 5 front sides, right frame 1, left frame 2 pass through the anti-collision frame of front side. The collision beam 3 is connected with the anti-collision fixing frame 11, and the pointed nose window 4 is installed between the two supporting beams 5, and a cavity is formed at the anti-collision beam 3, the right skeleton 1, the left skeleton 2 and the pointed nose window 4, and the right...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap