Feeding mechanism for counting and packaging machine

A technology of feeding mechanism and packaging machine, which is applied in the field of packaging, can solve the problems of a large number of workers, low packaging efficiency, and increased labor costs of enterprises, and achieve the effects of high accuracy of points, improvement of hygienic conditions, and reduction of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

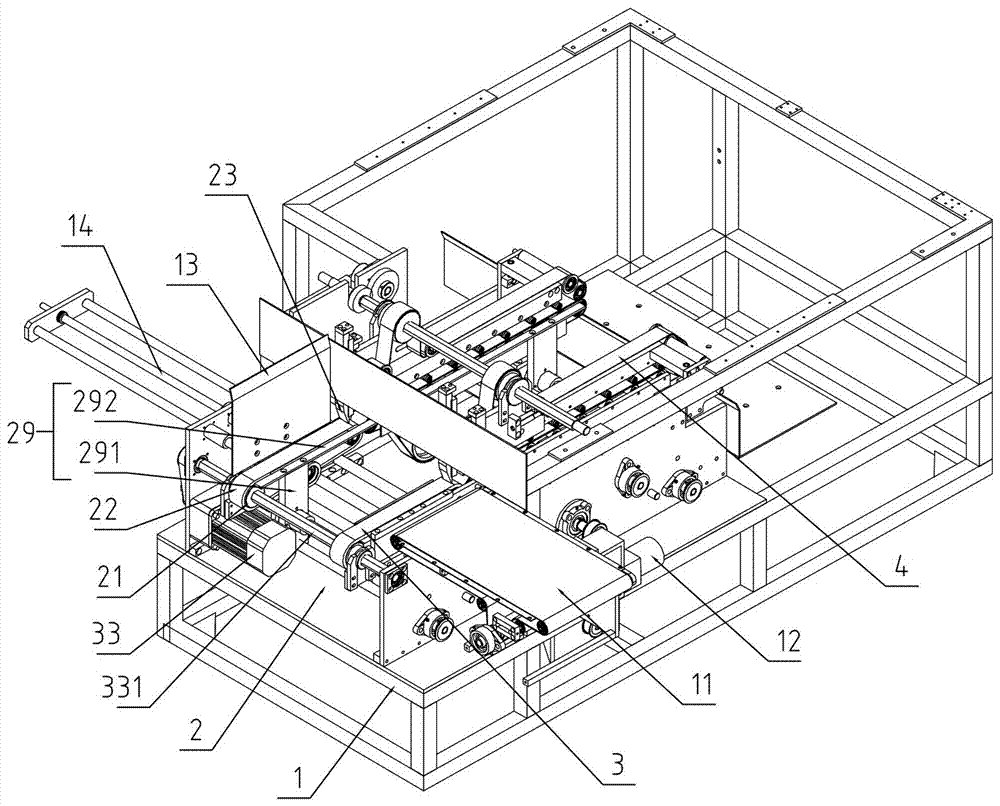

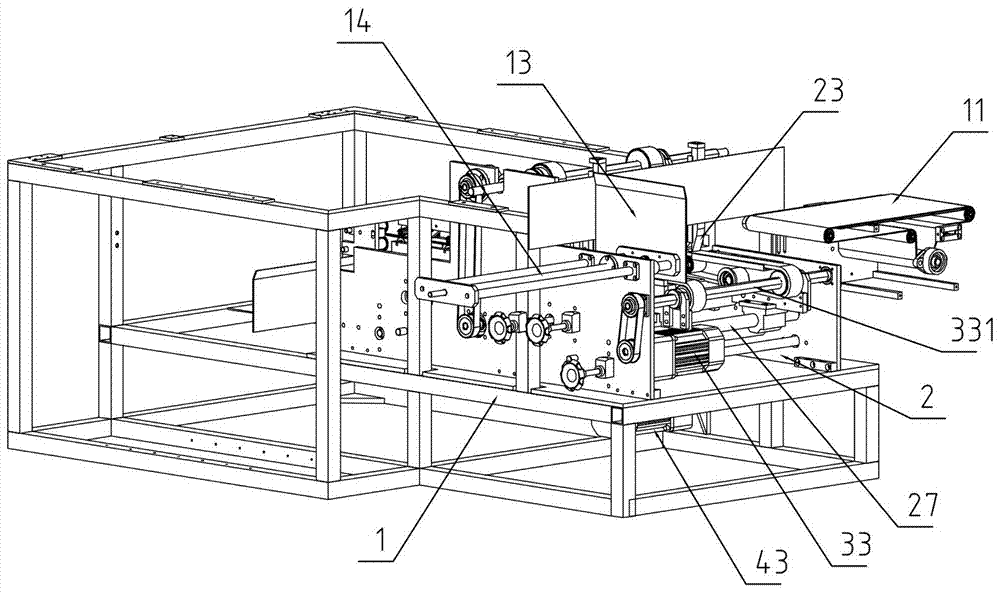

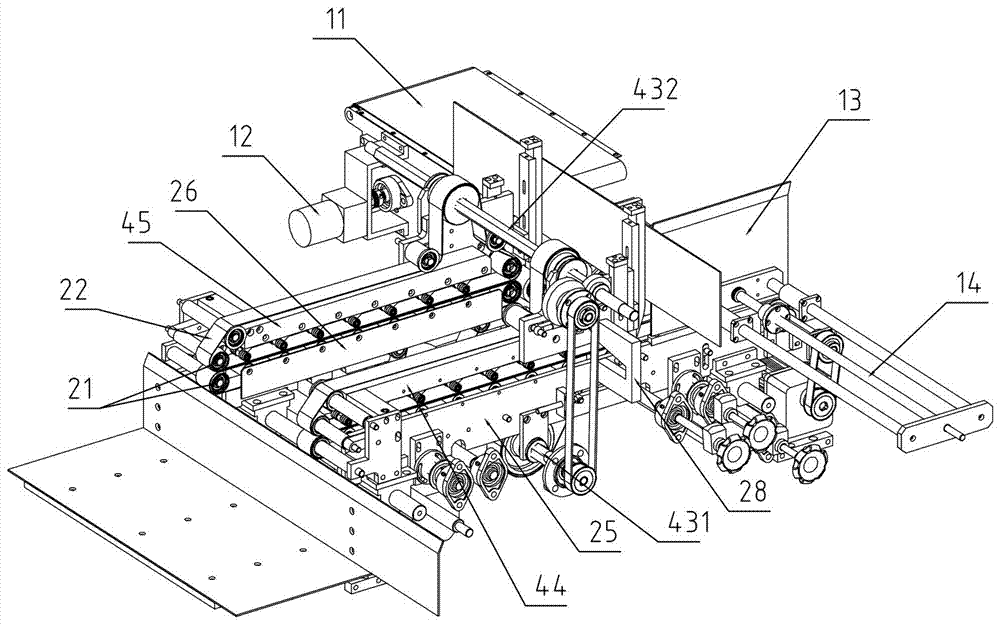

[0022] refer to Figure 1-6 As shown, a feeding mechanism for count packaging machine includes a mounting base 1 and a feeding conveying device 2 arranged on the mounting base 1, and the feeding conveying device 2 includes a front conveying group 3 sequentially arranged along its conveying direction and the rear conveying group 4, the preceding conveying group 3 includes a front left conveying frame 31 and a front right conveying frame 32 arranged para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com