A kind of polyester modified sponge and preparation method thereof

A polyester modification and sponge technology, applied in the field of sponge, can solve the problems of poor flame composite peel strength of sponge, poor use effect of sponge, excessive labor and other problems, achieve excellent tensile strength and elongation at break, and enhance the strength of polyurethane Combined peel strength with flame, reducing the effect of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

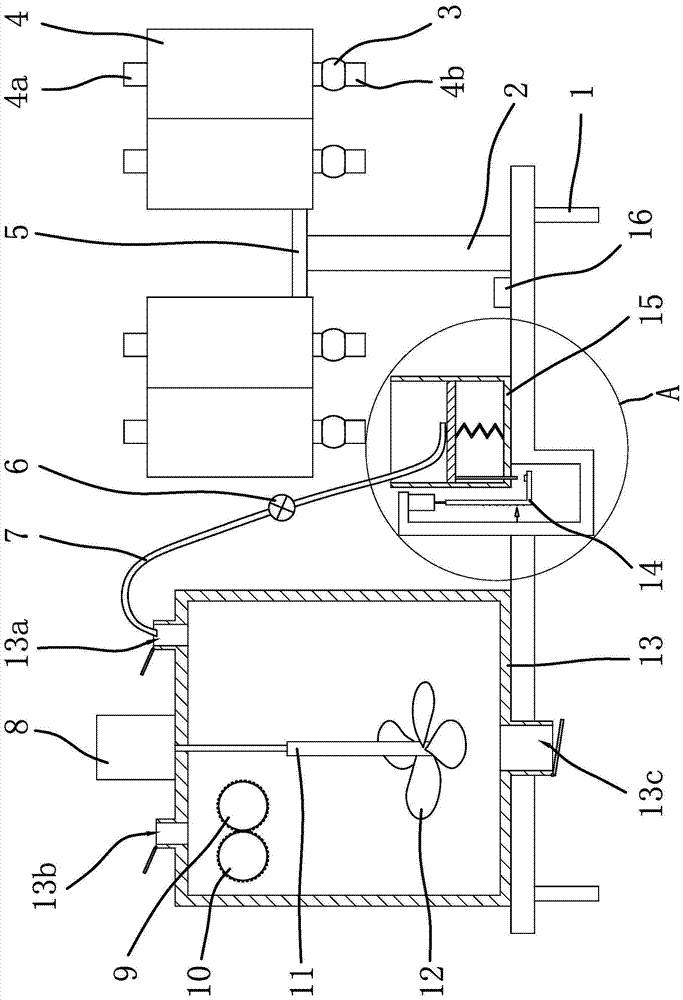

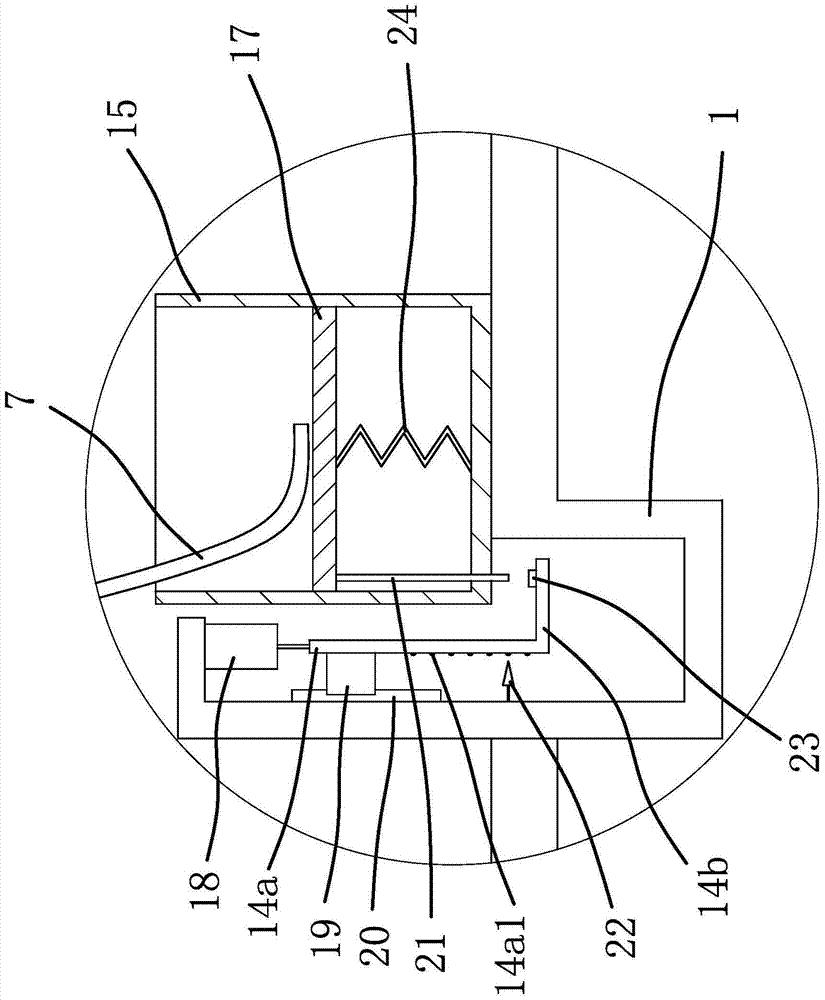

Method used

Image

Examples

Embodiment 1

[0052] The preparation method of the polyester modified sponge includes the following steps:

[0053] a. Purchase the required raw materials;

[0054] b. Add polyether polyol and polyester polyol to the stirring device, stir for 10 minutes, and the stirring speed is 200r / min;

[0055] c. Add dimethyl methylphosphonate, triethylenediamine and dibutyltin to the stirring device, stir for 5min, and the stirring speed is 200r / min;

[0056] d. Add the foam stabilizer, foaming agent and water to the stirring device, stir for 10 minutes, and the stirring speed is 200r / min;

[0057] e. Add toluene diisocyanate to the stirring device, stir for 0.5 min, the stirring speed is 100r / min, until the material liquid is milky white;

[0058] f. Spray the material liquid to the mold through a spray gun, let it stand in a water bath at 50℃, foam and solidify, demould after 20h, put it in an oven for drying, the drying temperature is 40℃, and the drying time is 20min, the finished product is obtained.

[005...

Embodiment 2

[0070] The preparation method of the polyester modified sponge includes the following steps:

[0071] a. Purchase the required raw materials;

[0072] b. Add the polyether polyol and polyester polyol to the stirring device, stir for 15 minutes, and the stirring speed is 250r / min;

[0073] c. Add dimethyl methylphosphonate, triethylenediamine and dibutyltin to the stirring device, stir for 8min, and the stirring speed is 250r / min;

[0074] d. Add the foam stabilizer, foaming agent and water to the stirring device, stir for 15 minutes, and the stirring speed is 250r / min;

[0075] e. Add toluene diisocyanate to the stirring device, stir for 1 min, and the stirring speed is 120r / min, until the material liquid is milky white;

[0076] f. Spray the material liquid to the mold through a spray gun, let it stand in a 65℃ water bath, foam and solidify, demould after 22h, put it in an oven for drying, the drying temperature is 50℃, and the drying time is 30min, the finished product is obtained.

[...

Embodiment 3

[0088] The preparation method of the polyester modified sponge includes the following steps:

[0089] a. Purchase the required raw materials;

[0090] b. Add the polyether polyol and polyester polyol to the stirring device, stir for 20 minutes, and the stirring speed is 350r / min;

[0091] c. Add dimethyl methylphosphonate, triethylenediamine and dibutyltin to the stirring device, stir for 10min, and the stirring speed is 300r / min;

[0092] d. Add the foam stabilizer, foaming agent and water to the stirring device, stir for 20 minutes, and the stirring speed is 300r / min;

[0093] e. Add toluene diisocyanate to the stirring device, stir for 3 minutes, the stirring speed is 150r / min, until the material liquid is milky white;

[0094] f. Spray the material liquid to the mold through a spray gun, let it stand in a water bath at 80℃, foam and solidify, demould after 24h, put it in an oven for drying, the drying temperature is 60℃, and the drying time is 40min, the finished product is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com