Substrate delivery method

A feeding method and substrate technology, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of low processing efficiency, danger, and low yield of flexible printed circuit boards, so as to improve work efficiency and avoid Direct contact, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

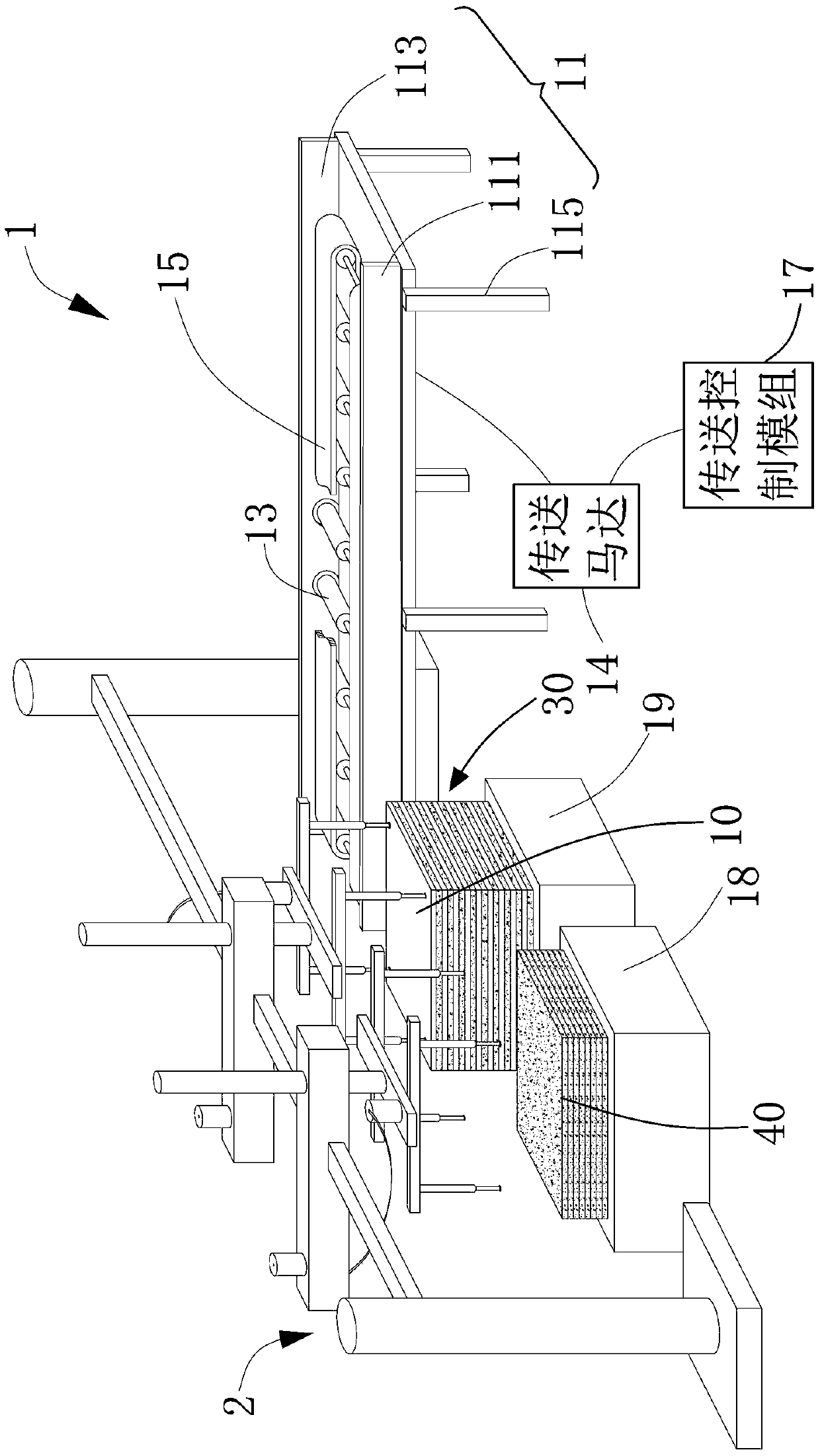

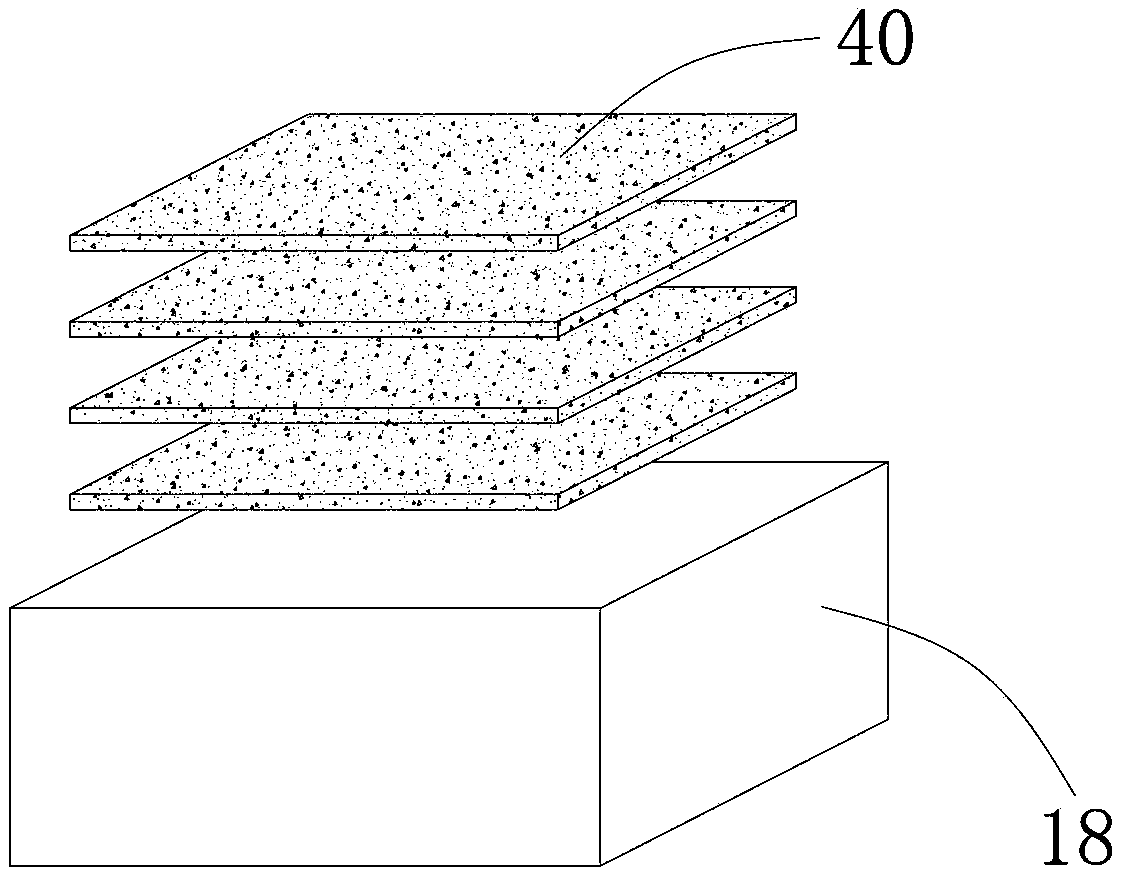

[0031] see figure 1 , is a schematic perspective view of the first embodiment disclosed in the present invention, using the substrate transfer pick-and-place device to put the substrate into the processing line. The processing line 1 is used to transfer the substrate 10 to be processed by the corresponding station. At the same time, a substrate transport pick-and-place device 2 is provided on the side of the processing line 1 and adjacent to the processing line 1 . The substrate conveying pick-and-place device 2 is used to put the stacked substrates 10 into the processing line 1 for processing, and the stacked substrates 10 form a stack 30 and place them at a set position. In this embodiment, the substrate 10 may be a copper-clad substrate or a semi-finished product during processing of a printed circuit board.

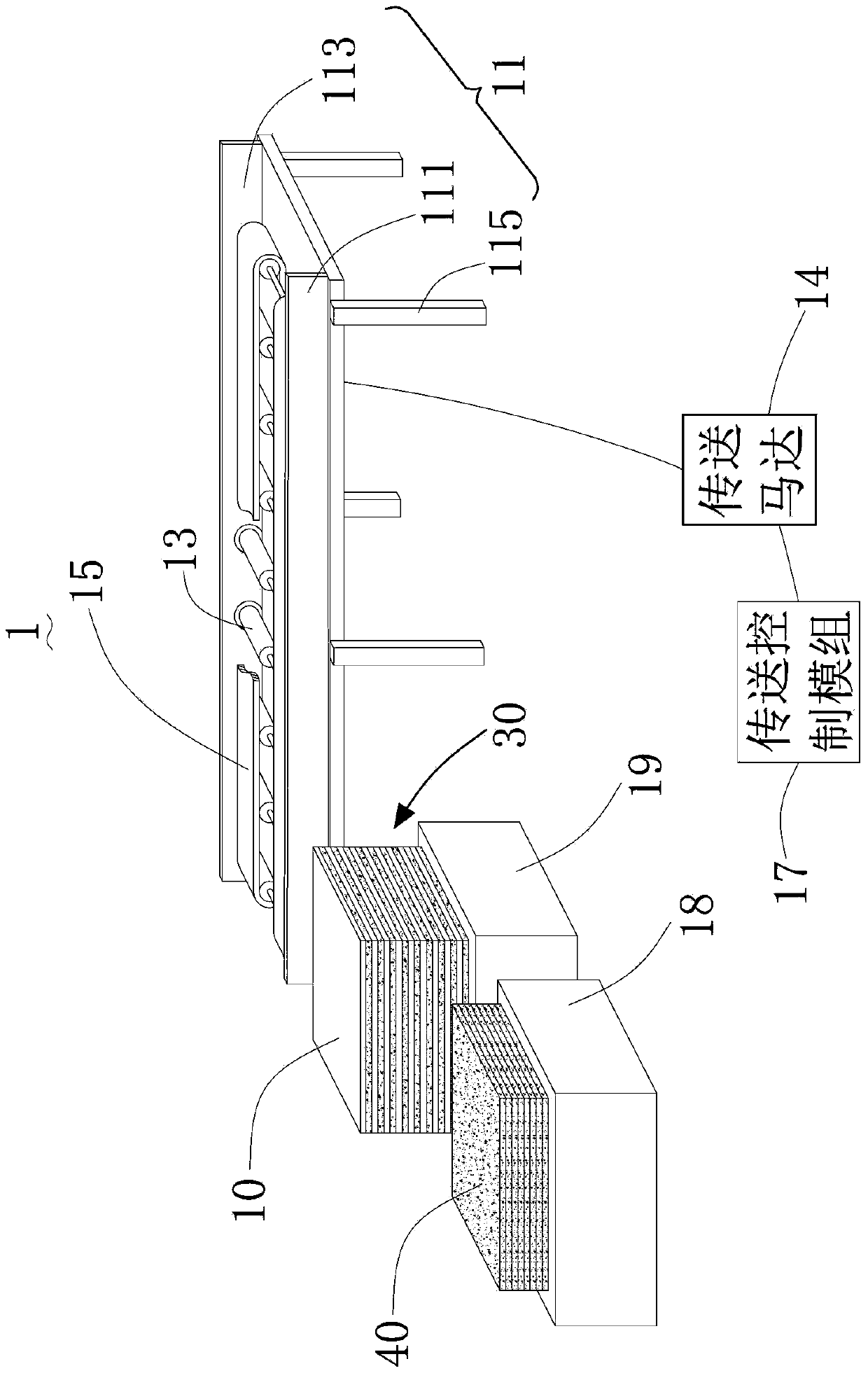

[0032] see figure 2 ,yes figure 1 A schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com