Riveting machine with hand injury prevention structure for scaffold fastener production

The technology of fasteners and scaffolding is applied in the field of riveting machines with an injury-proof hand structure, which can solve the problems of low safety of riveting machines, and achieve the effects of avoiding manual manual contact, improving the safety of devices, and avoiding contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

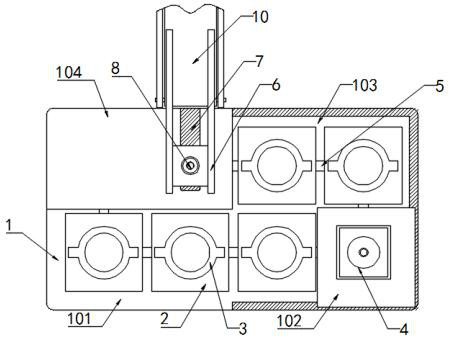

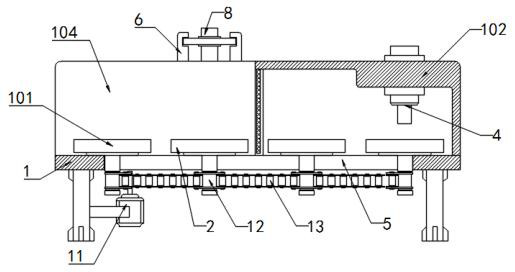

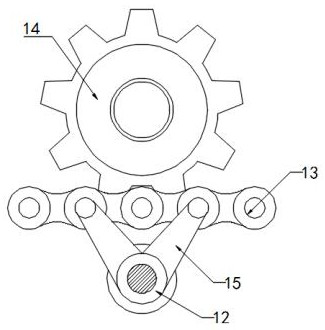

[0032] Example 1, please refer to Figure 1-5 , a riveting machine with an anti-injury structure for the production of scaffold fasteners, including a workbench 1, a riveting machine 4 is arranged on the workbench 1, and the workbench 1 is sequentially provided with a feeding area 101, a press The riveting area 102, the transfer area 103 and the blanking area 104, the workbench 1 is provided with a rectangular slideway 5, and the inside of the slideway 5 is equidistantly provided with a plurality of conveying platforms 2, and the top of the riveting area 102 is fixedly connected with A riveting machine 4, and a protective cover is fixedly connected to the riveting area 102 and the transfer area 103, a hydraulic cylinder 8 is slidably connected to the top of the blanking area 104, and an electromagnet 16 is fixedly connected to the output end of the hydraulic cylinder 8, and the working table 1 is provided with a chain 13 corresponding to the slideway 5, and a gear plate 14 mes...

Embodiment 2

[0033] Example 2, please refer to Figure 1-5 , a riveting machine with an anti-injury structure for the production of scaffold fasteners, including a workbench 1, a riveting machine 4 is arranged on the workbench 1, and the workbench 1 is sequentially provided with a feeding area 101, a press The riveting area 102, the transfer area 103 and the blanking area 104, the workbench 1 is provided with a rectangular slideway 5, and the inner side of the slideway 5 is equidistantly provided with a plurality of conveying platforms 2, and the upper inner side of the conveying platform 2 is provided with a placement slot 3, and the shape of the placement groove 3 is made according to the style of the fastener, there are two groups of rollers 17 in an equidistant annular array on the inner wall of the conveying platform 2, and the two groups of rollers 17 are arranged symmetrically about the horizontal centerline of the conveying platform 2, and The rollers 17 protrude from the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com