Polymer liquid-crystal composition and liquid crystal display apparatus comprising same

A polymeric liquid crystal and composition technology, applied in liquid crystal materials, instruments, nonlinear optics, etc., can solve problems such as increased energy consumption, uneven display, and impact on optical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

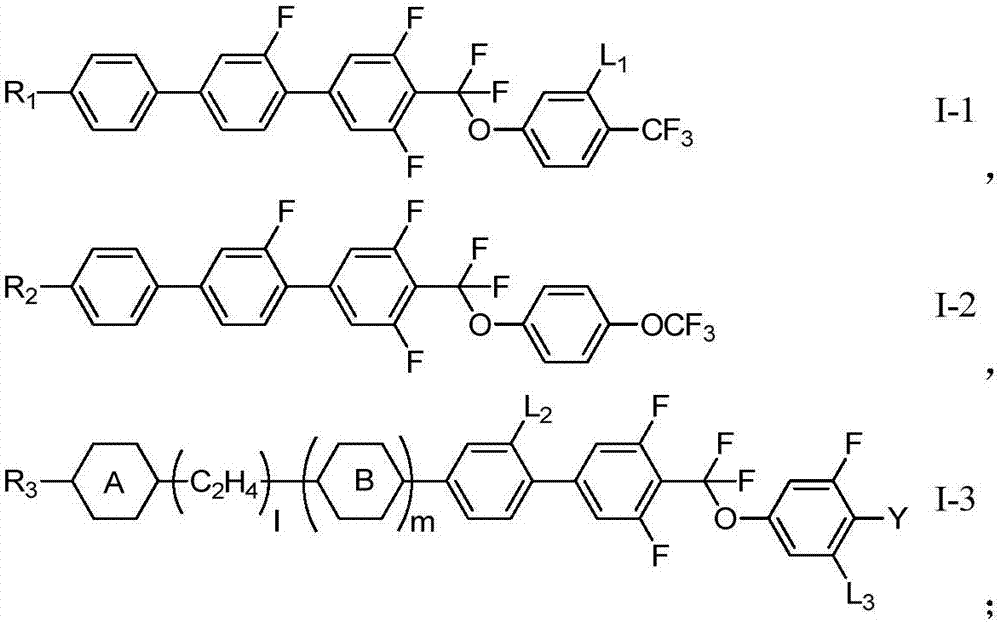

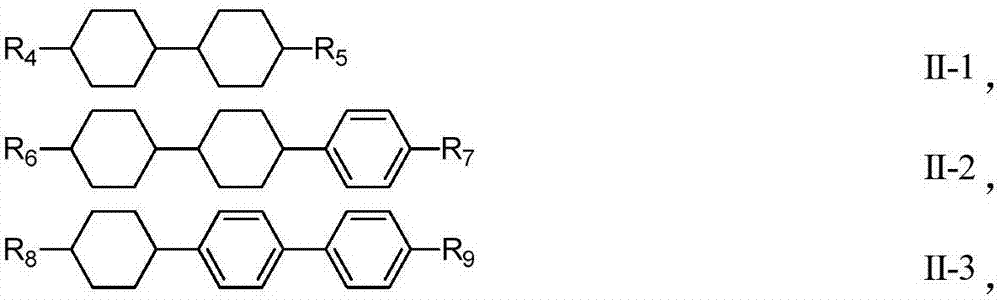

Method used

Image

Examples

Embodiment 1

[0167] The liquid crystal composition LC-2 of Example 1 was formulated according to the compounds and weight percentages listed in Table 3, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0168] Table 3 liquid crystal composition formula and test performance thereof

[0169]

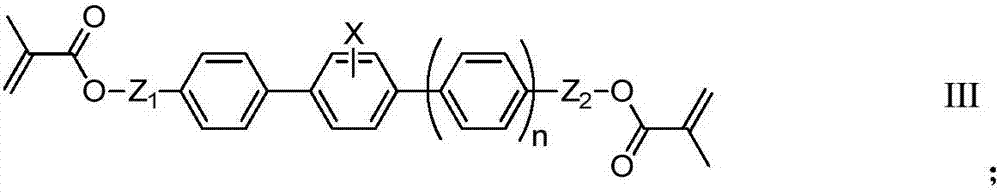

[0170] Add 0.3% of the compound represented by the following formula III-1 to 99.7% of the above-mentioned liquid crystal composition LC-2 to prepare a polymerizable liquid crystal composition LCM-2. The physical properties of the obtained LCM-2 are almost equal to those of LC-2. no change.

[0171]

[0172] The residual RM of LCM-1 was tested at 0.105%.

[0173] Compared with Example 1 and Comparative Example 1, under the conditions that the clearing point, refractive index anisotropy, and dielectric anisotropy are basically the same, RM has a faster polymerization rate, lower residue, and has a ...

Embodiment 2

[0182] The liquid crystal composition LC-4 of Example 2 was formulated according to the compounds and weight percentages listed in Table 5, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0183] Table 5 liquid crystal composition formula and test performance thereof

[0184]

[0185] Add 0.25% of the compounds represented by the following formula III-1 and 0.15% respectively to 99.6% of the above-mentioned liquid crystal composition LC-4 to prepare the polymerizable liquid crystal composition LCM-4, and the resulting LCM The physical property values of -4 hardly changed from those of LC-4.

[0186]

[0187] The RM residue tested for LCM-4 was 0.08%.

[0188] Compared with Example 2, under the condition that the clearing point, refractive index anisotropy, and dielectric anisotropy are basically the same, RM has a faster polymerization rate, lower residue, and has a st...

Embodiment 3

[0197] The liquid crystal composition LC-6 of Example 3 was formulated according to the compounds and weight percentages listed in Table 6, and it was filled between the two substrates of the liquid crystal display for performance testing. The test data are shown in the following table:

[0198] Table 6 liquid crystal composition formula and test performance thereof

[0199]

[0200] Add 0.25% of the compound represented by the following formula III-1 to 99.75% of the above-mentioned liquid crystal composition LC-6 to prepare the polymerizable liquid crystal composition LCM-6. The physical properties of the obtained LCM-6 are almost equal to those of LC-6 no change.

[0201]

[0202] The RM residue tested for LCM-6 was 0.117%.

[0203] Compared with Example 3 and Comparative Example 3, under the conditions that the clearing point, refractive index anisotropy, and dielectric anisotropy are basically the same, RM has a faster polymerization rate, lower residue, and has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com