A valve rotation mechanism

A technology of rotating mechanisms and valves, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as easy formation of carbon deposits, uneven wear, excessive wear of valves, etc., to alleviate carbon deposits and avoid excessive thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

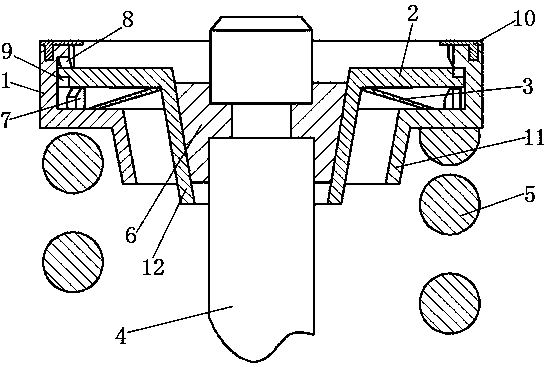

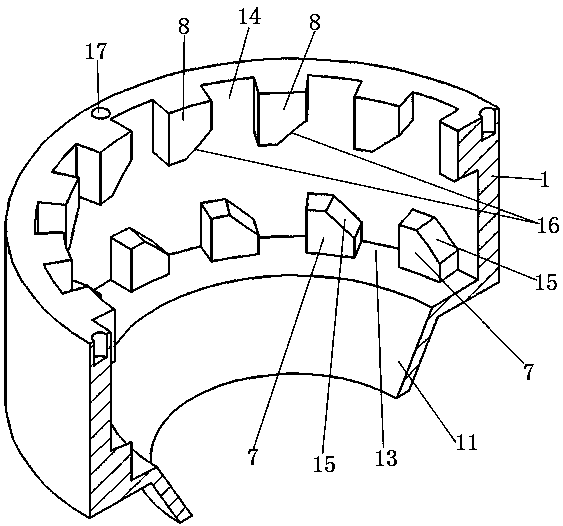

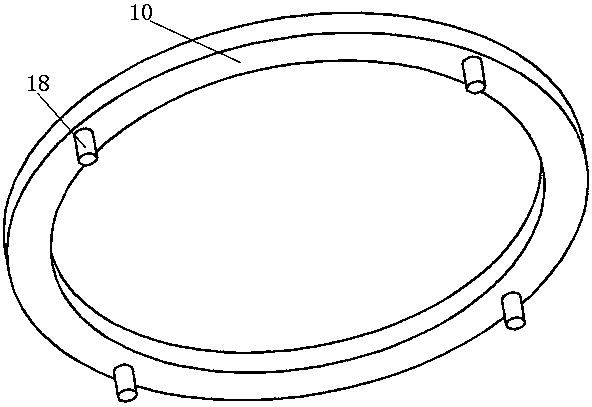

[0019] Such as figure 1 A valve rotating mechanism shown includes a valve stem 4, a rotating member 2 fixedly mounted on the valve stem 4, a valve spring seat 1 sleeved on the periphery of the rotating member 2, and a valve spring 5 pushing upward against the valve spring seat 1; Part 2 comprises a gear part, and the periphery of the gear part is provided with external teeth 9, and the side wall of the external teeth 9 facing the first direction of the circumferential direction of the gear part is provided with an upper inclined surface 20 and a lower inclined surface 19, and the upper inclined surface 20 is from top to bottom along the The first direction is inclined, and the lower slope 19 is inclined toward the first direction from bottom to top; the valve spring seat 1 is provided with a cavity, and the upper and lower ends of the cavity are provided with avoidance open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com