A split-shaft external combustion aerodynamic device and conversion method

An aerodynamic and external combustion technology, applied to gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of long start-up process of steam power devices, high and low calorific value fuels, inflexible start and stop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the present invention, the connection relationship of each component in the device only represents the sequence, which can be direct or indirect connection, for example, the air heating furnace is connected to the compressor, then the air heating furnace and the compressor can be connected Direct connection, also can contain other parts between, realize indirect connection.

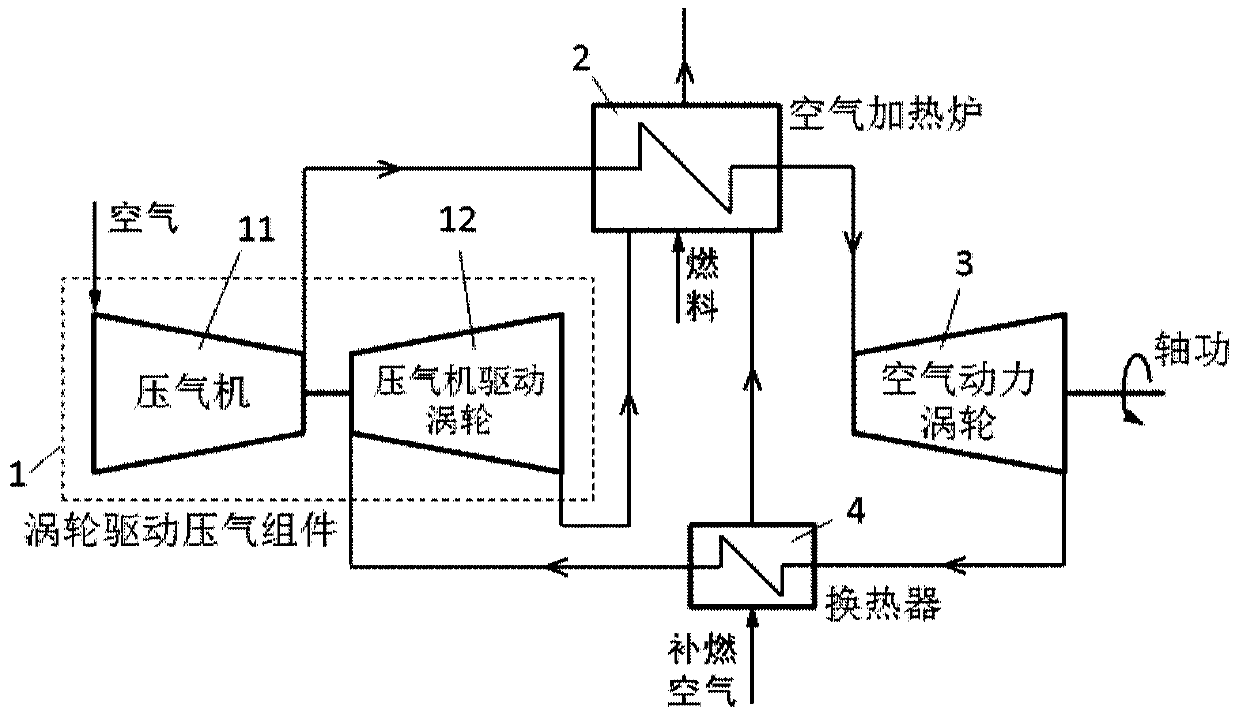

[0032] The invention provides a split-shaft external-combustion aerodynamic device, including a turbine-driven compressed air assembly, an air heating furnace, an aerodynamic turbine and a heat exchanger, wherein,

[0033] The turbine-driven compressor assembly includes a coaxially arranged compressor and a compressor-driven turbine, and the compressor is driven by the compressor-driven turbine for compressing air to form compressed air;

[0034] The air heating furnace inputs compressed air for heating the compressed air to form high-temperature compressed air;

[0035] The aerodynamic turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com