Heat sink

A technology of heat dissipation device and heat pipe, which is applied to electrical components, electric solid state devices, circuits, etc., can solve problems such as non-conformity with heat dissipation devices, and achieve the effects of improving thermal conductivity, improving heat dissipation efficiency, and increasing heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

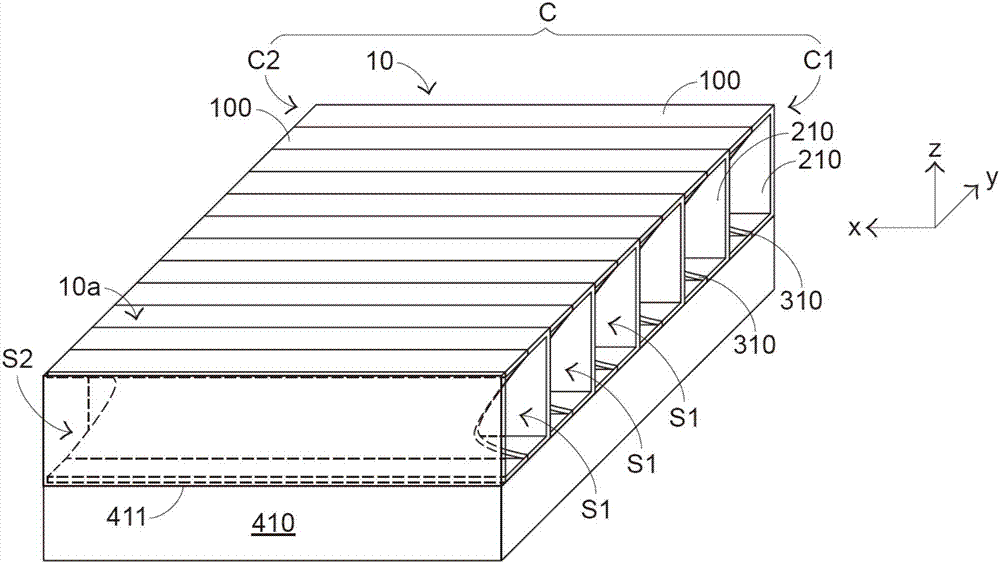

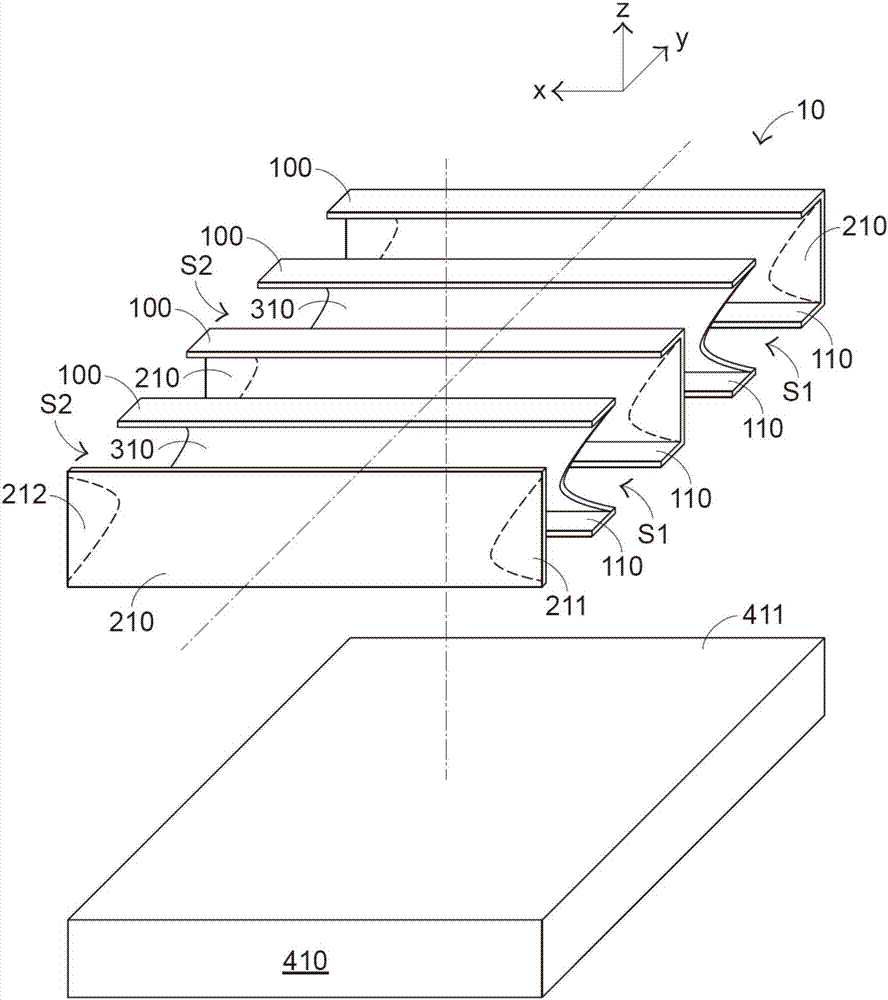

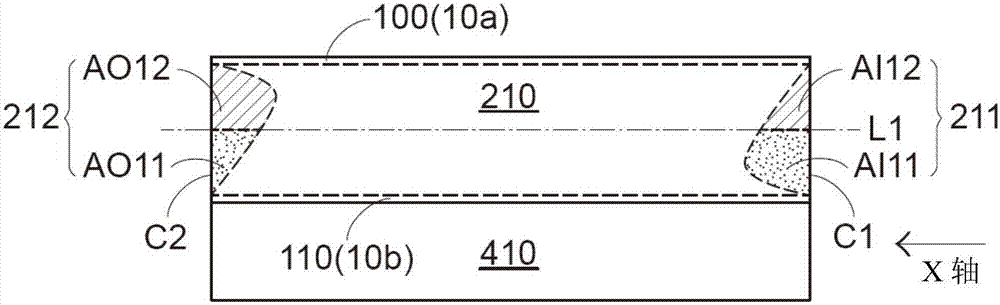

[0031] First of all, please refer to the three-axis directions shown in the figures of each embodiment, and define the X-axis direction as the front-to-back direction of the heat sink; the Y-axis direction is the left-right direction of the heat sink, which is the sequence of the fins described in the present invention. The axial direction of the radiator is composed of staggered intervals; the Z-axis direction is the up and down direction of the radiator. In the description of the present invention, the heating element is relatively arranged below the radiator for the convenience of explanation, but it is not limited thereto. .

[0032] see Figure 1A to Figure 1C , Figure 1A It is a three-dimensional schematic view of the first embodiment of the heat dissipation device of the present invention. Figure 1B for Figure 1A An exploded view of a partial implementation of the first embodiment of the heat sink shown. Figure 1C for Figure 1A In the heat dissipation device show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com