A lithium-ion battery winding assembly system

A lithium-ion battery and assembly system technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as failures and shutdowns, unbalanced flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the technical solution of the present invention will be described in detail through specific examples.

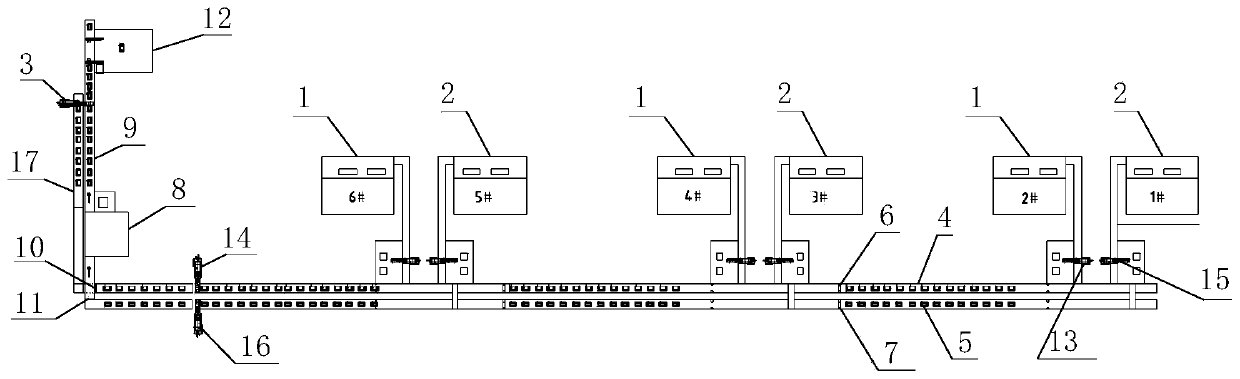

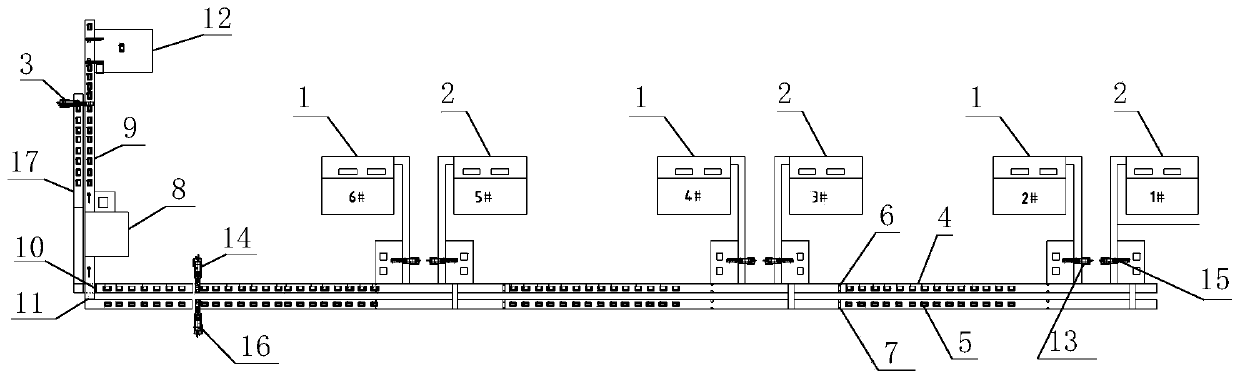

[0028] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a lithium-ion battery winding assembly system proposed by the present invention.

[0029] refer to figure 1 , a lithium-ion battery winding and assembling system proposed by an embodiment of the present invention includes: a first winding device 1 for producing a winding core A, a second winding device 2 for producing a winding core B, and a The assembly manipulator 3 that assembles the core A and the core B together, and the conveying line for transporting the core A and the core B produced by the first winding device 1 and the second winding device 2 to the assembly manipulator 3 ,in:

[0030] Both the first winding device 1 and the second winding device 2 are winding machines. The conveying lines comprise a first conveying line 4 for conveying the winding A and a second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap