A commutator hook chamfering device

A technology of a chamfering device and a commutator, which is applied in the field of commutators, can solve the problems affecting the chamfering of the hook of the commutator and the absence of the hook of the commutator, and achieve the effects of improving the chamfering efficiency and reducing the positioning error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

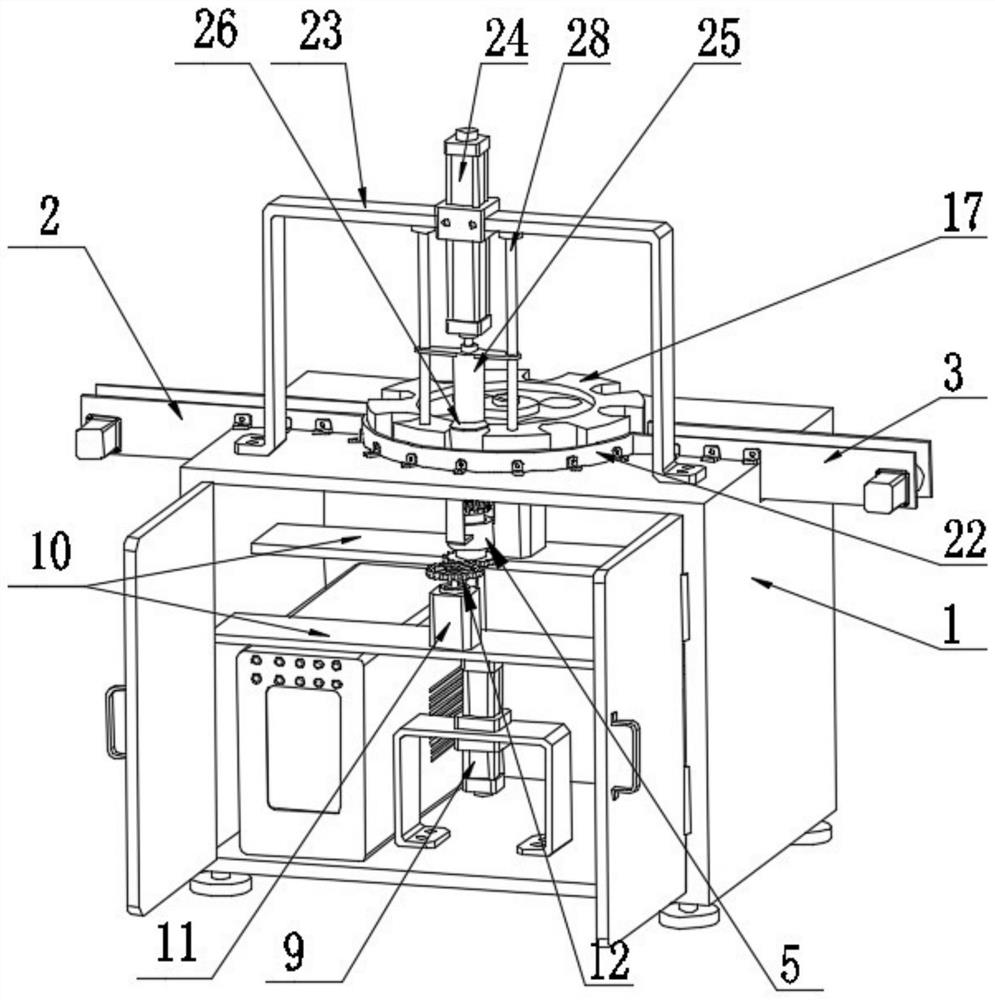

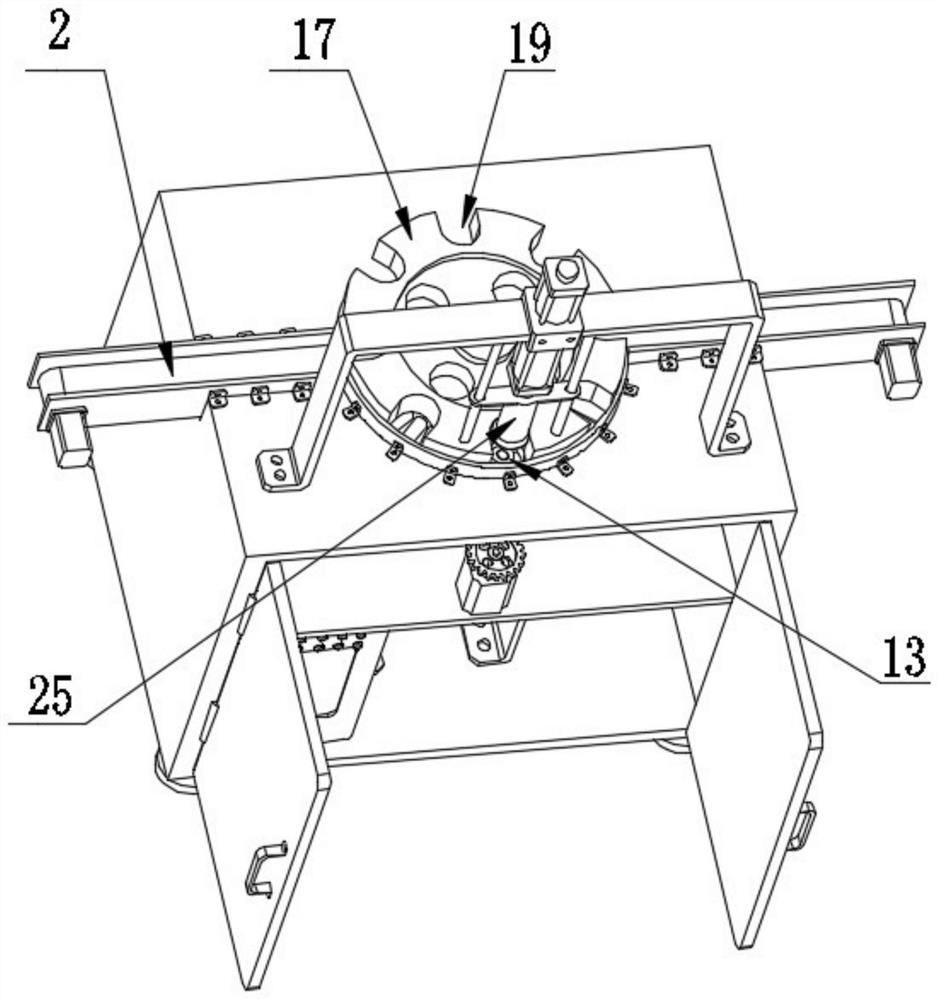

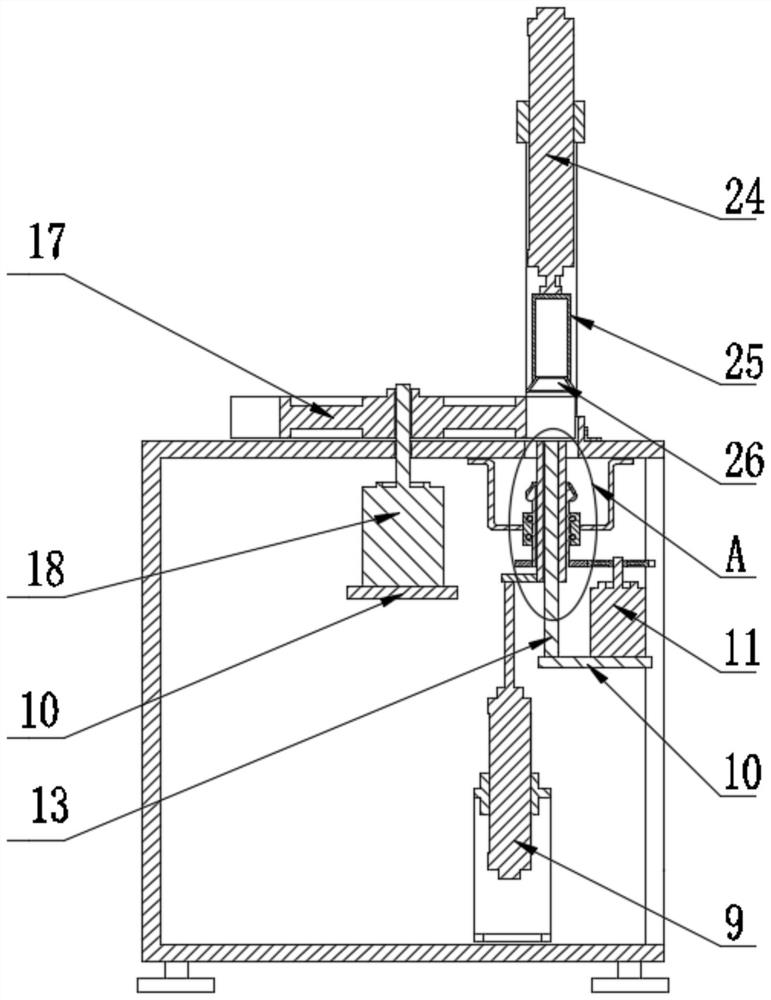

[0036] A commutator hook chamfering device of this embodiment, refer to Figure 1-9: Including the machine body 1, the left and right parts of the body 1 are respectively provided with a feeding conveyor belt 2 and an unloading conveyor belt 3; There is a chamfering hole 4 on the top of the body, a chamfering mechanism is provided on the front side of the top of the body 1, and a positioning mechanism is arranged in the front of the body 1. The positioning mechanism includes two sets of front and rear symmetrical brackets fixed in the upper layer of the front of the body 1 and aligned with the chamfering. The swivel 5 coaxial with the angular hole 4, the rotating drum 6 connected in the rotating ring 5, the frustum part 7 arranged on the top of the rotating drum 6 and communicating with the rotating drum 6, and the outer wall of the circumference of the bottom of the rotating drum 6 The transmission gear 8, the lifting cylinder 9 fixed in the lower layer of the front part of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap