Power battery heat treatment method, device and electric vehicle

A heat treatment method and power battery technology, which are applied in secondary batteries, battery temperature control, circuits, etc., can solve the problems of low reliability and safety, single temperature control of power batteries, and inability to collect timely and accurately. The effect of user experience and performance reduction and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described in detail below, examples of which are shown in the accompanying drawings, in which the same or similar reference numerals refer to the same or similar elements or elements with the same or similar functions throughout. The embodiments described below with reference to the drawings are exemplary and are intended to explain the present invention, but should not be construed as limiting the present invention.

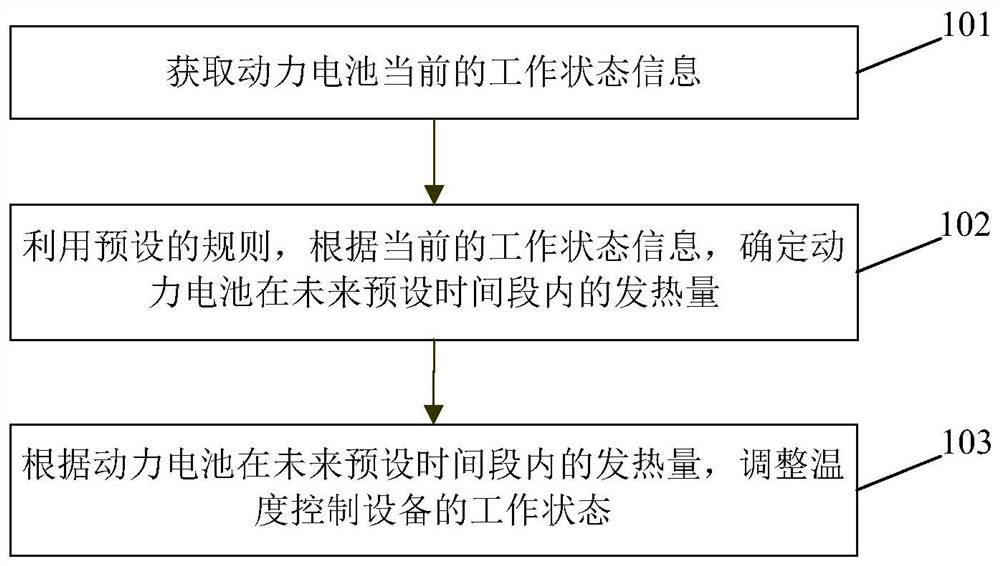

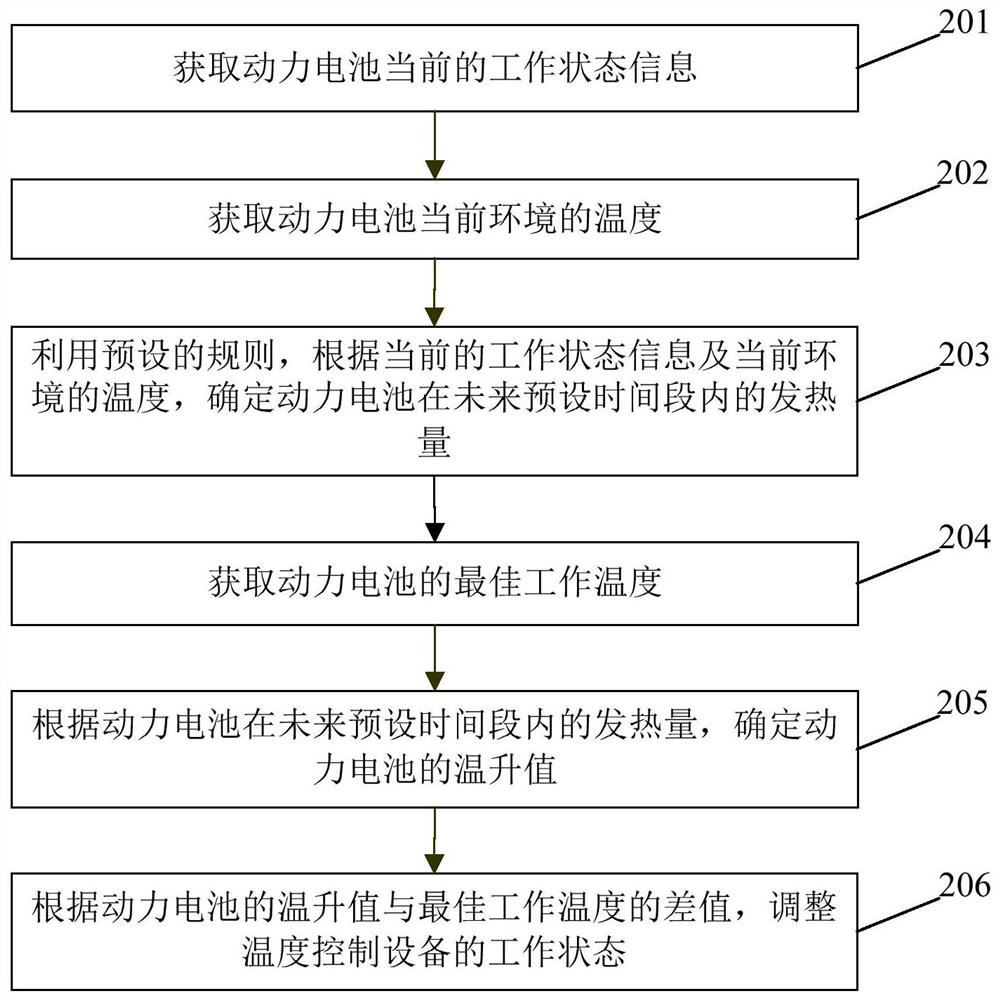

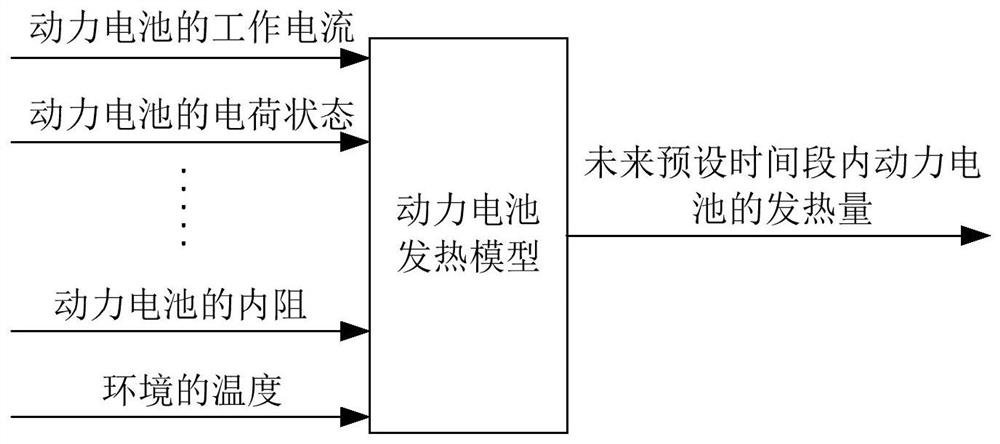

[0055] The invention mainly aims at the problem that in the prior art, the performance, reliability and safety are reduced, the service life is shortened, and even safety risks exist due to the fact that the power battery cannot be timely and accurately regulated to the optimal working temperature under the condition of overheating or supercooling, and a heat treatment method for the power battery is provided. The heat treatment method of the power battery provided by the invention comprises the following steps: fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com