High-strength and fireproof electrical cabinet

An electrical cabinet, high-strength technology, applied in the direction of fire rescue, substation/distribution device casing, etc., can solve the problems of explosion, increase the weight of the box, disadvantageous use, etc., to reduce manufacturing costs, improve explosion-proof performance, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

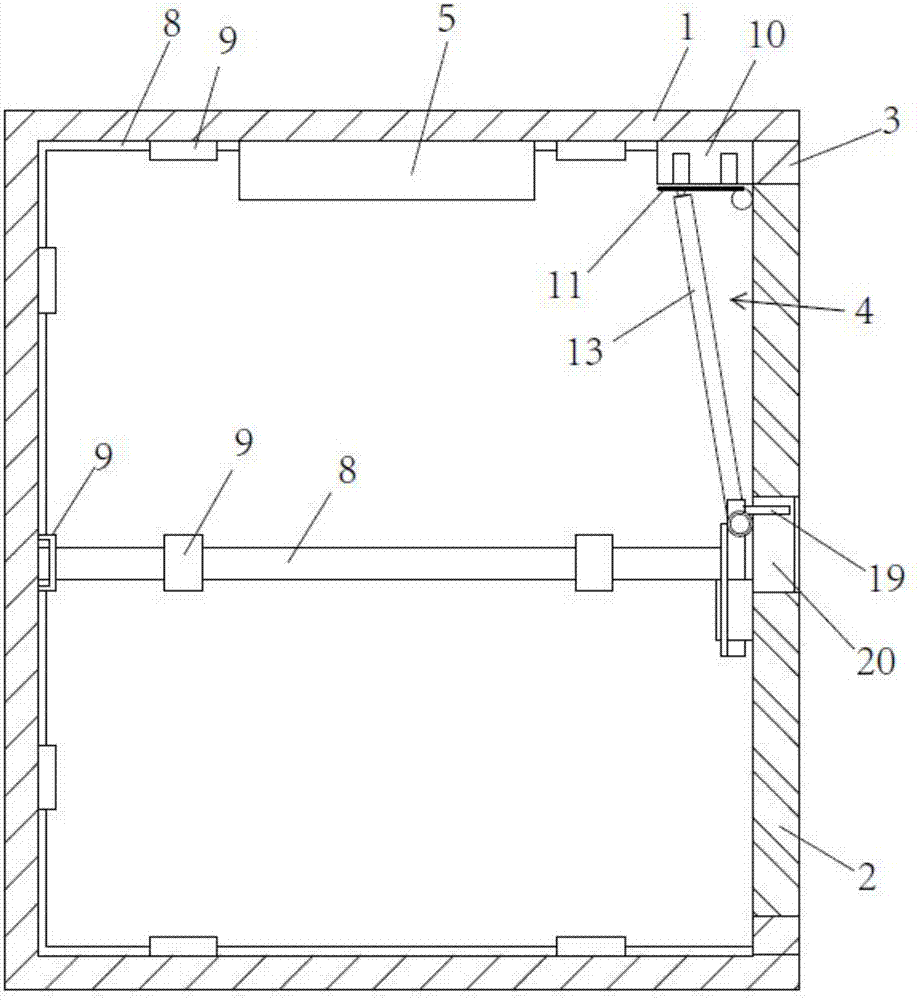

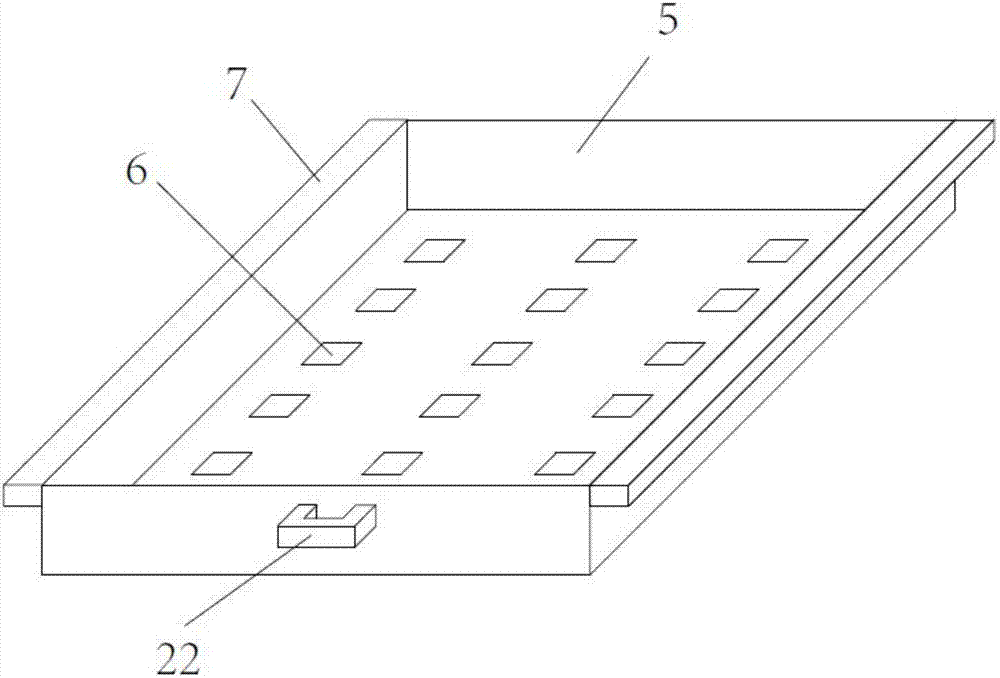

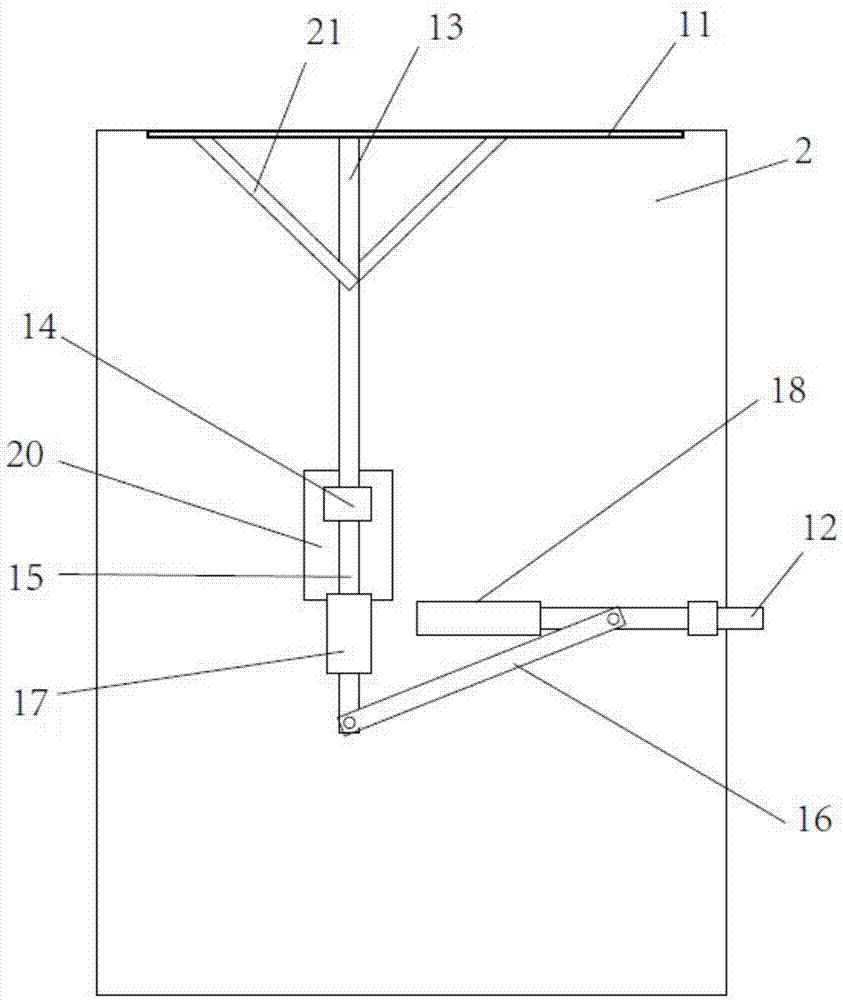

[0021] refer to figure 1 and figure 2 As shown, a high-strength fireproof electrical cabinet includes a cabinet 1 and a door 2, a door frame 3 is arranged on the cabinet, a door hinge and a lock body 4 are arranged between the door and the door frame, and the door rotates along the door hinge , to realize the switching effect, the lock body can ensure the locking effect of the box door, a fire extinguishing box 5 is arranged on the top inside of the cabinet, a number of powder drop holes 6 are opened on the bottom of the fire extinguishing box, and fire extinguishing powder is arranged in the fire extinguishing box, and the fire extinguishing powder passes through Hot-melt adhesive film covering setting, when there is an open flame, the hot-melt adhesive film will be melted, and the internal fire extinguishing powder will fall directly from the powder drop hole to realize fire extinguishing, and the hot-melt adhesive film will not ignite, avoiding secondary open flame.

[0...

Embodiment 2

[0028] The difference between Embodiment 2 and Embodiment 1 is that the magnetic base cooperates with the magnet to form a magnetic base, the magnet is connected to the rotating part, the rotating part is connected to the lock cylinder, the lock cylinder is set on the cabinet, and the rotation of the lock cylinder drives the rotation of the rotation part , the rotating part drives the magnet to rotate, and the magnetic switch effect of the magnetic base can be realized. When the magnetic force is turned on, the magnetic rotating plate can be sucked up to achieve the locking effect. When the magnetic force is turned off, the magnetic rotating plate cannot be sucked up. The effect of unlocking is realized by falling due to its own weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com