Construction method for magnetic loss type shrinking ratio wave-absorbing material

A technology of wave-absorbing materials and construction methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as limitations, achieve the effect of ensuring design accuracy and facilitating manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

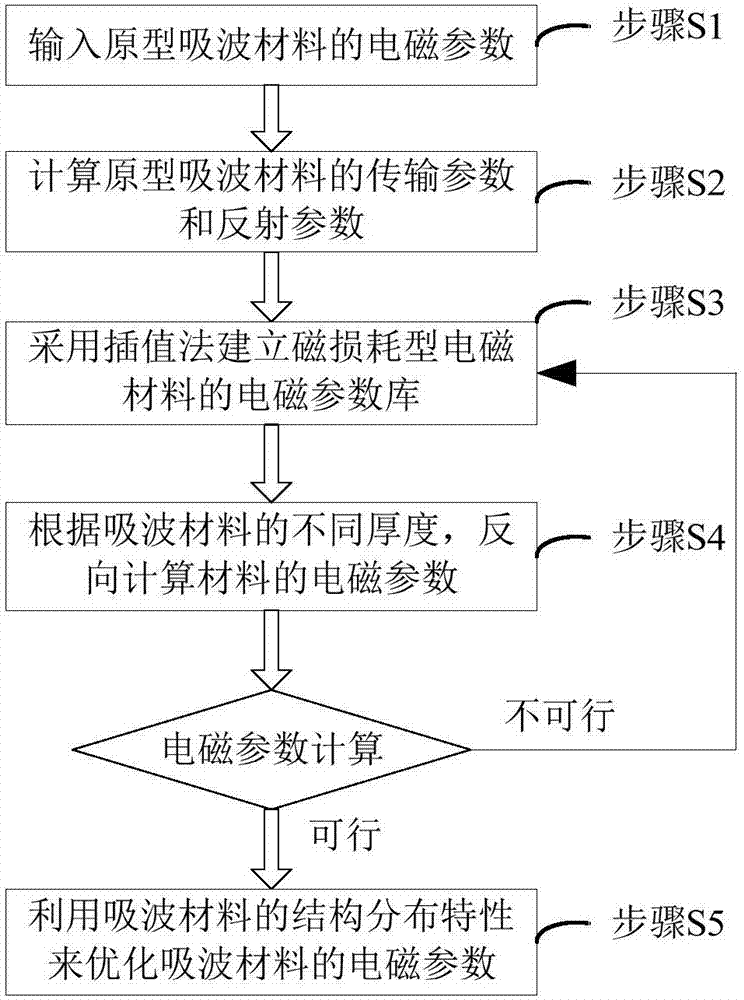

[0094] 1. Input the electromagnetic parameters of the prototype uniform absorbing material;

[0095] Set the electromagnetic parameters, frequency and scaling factor of the prototype, such as ε=22.3-j1.1, μ=3.2-j2.6, prototype frequency f=5GHz, scaling factor s=2, thickness d=0.5mm, the The scaled frequency f can be obtained when s = 10GHz.

[0096] 2. Calculate the transmission parameters and reflection parameters of the prototype uniform absorbing material;

[0097] According to the electromagnetic parameters of the absorbing material and the thickness of the prototype absorbing material, the reflection coefficient and transmission coefficient are calculated using the transmission matrix equation of the single-layer material, and the results are as follows:

[0098] T=e -jγL =0.75-j0.37.

[0099] reflection parameter transfer parameters

[0100] 3. Establish the electromagnetic parameter library of magnetic loss electromagnetic materials;

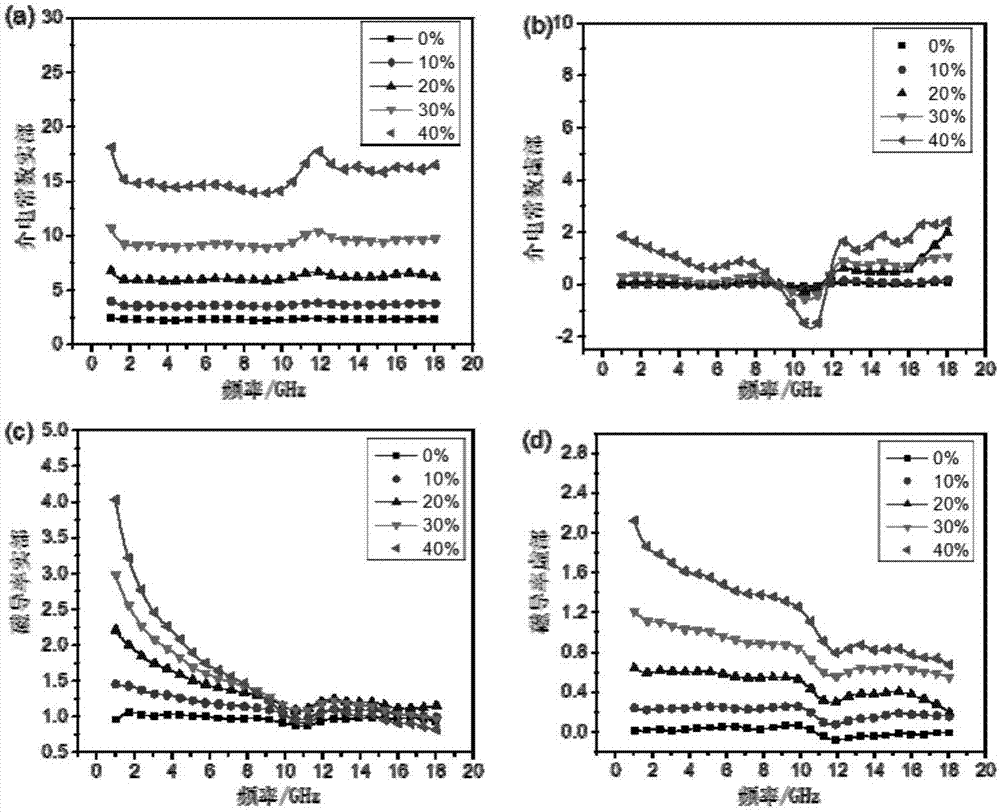

[0101] The establishme...

Embodiment 2

[0109] 1. Input the electromagnetic parameters of the prototype uniform absorbing material;

[0110] Set the electromagnetic parameters, frequency and scaling factor of the prototype, such as ε=22.03-j1.31, μ=3.71-j2.53, prototype frequency f=4GHz, scaling factor s=3, thickness d=1mm, at this time The scaled frequency f can be obtained s = 12GHz.

[0111] 2. Calculate the transmission parameters and reflection parameters of the prototype uniform absorbing material;

[0112] According to the electromagnetic parameters of the absorbing material and the thickness of the prototype absorbing material, the reflection coefficient and transmission coefficient are calculated using the transmission matrix equation of the single-layer material, and the results are as follows:

[0113] T=e -jγL =0.42-j0.59.

[0114] reflection parameter transfer parameters

[0115] 3. Establish the electromagnetic parameter library of magnetic loss electromagnetic materials;

[0116] Referring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com