Tapping wrench with LED lamp

A technology of LED lights and handles, which is applied in the field of processing tools, can solve problems such as difficult to drive in and laborious, and achieve the effects of good light, simple structure, and increased torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but do not limit protection scope and application scope of the present invention:

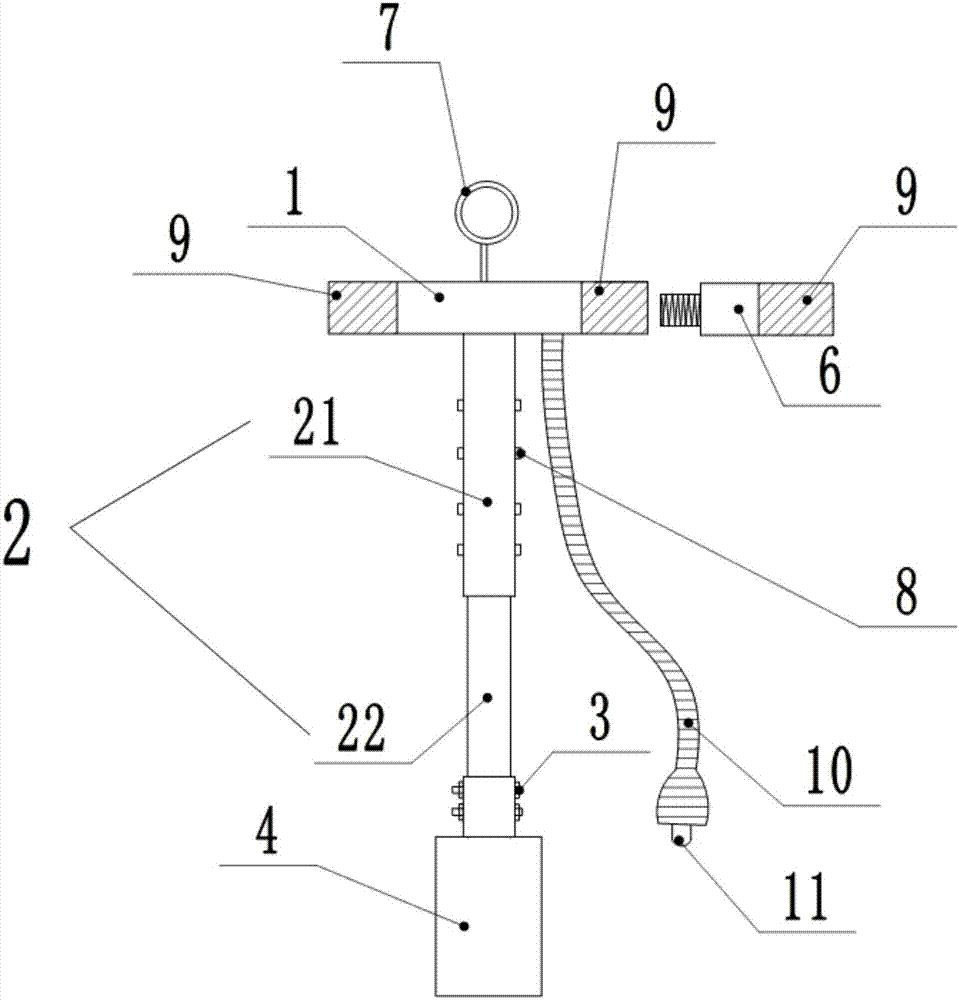

[0013] Such as figure 1 As shown, a tapping wrench with LED lights includes a handle 1, a connecting rod 2 and a collet 4. Both ends of the handle 1 are provided with internal threaded holes with openings facing outward, and one or both ends of the handle 1 can be passed through the internal thread. Hole is threadedly connected with the extension handle 6 of screw rod, handle 1 two ends are provided with anti-slip sleeve 9, and the end of extension handle 6 away from its screw rod is provided with anti-slip sleeve 9, and anti-slip sleeve adopts elastic silica gel to make, can avoid torsion skidding. Connecting rod 2 comprises outer connecting rod 21 and the inner connecting rod 22 that can be telescopic in outer connecting rod 21, and inner connecting rod 22 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com