Non-sticky type anti-sliding mechanical speed reducer cover with bolt hole

A bolt hole and cover technology, applied in mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as reduced work efficiency, inconvenient opening of the cover, and easy detachment of reinforcing ribs, so as to achieve extended use. The effect of longevity, not easy to let go, not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

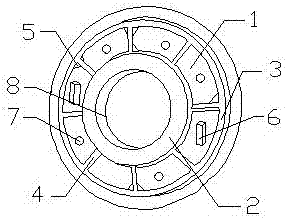

[0017] see figure 1 , the present invention is a non-stick type reducer cover with bolt holes for anti-slip machinery, which includes a reducer cover body 1, the reducer cover body 1 is in the shape of a ring, and the surface of the reducer cover body 1 is provided with different Adhesive layer, the front of the reducer cover body 1 is respectively provided with an inner flange 2 and an outer flange 3 from the inside to the outside, and the inner flange 2 and the outer flange 3 are all in the shape of a ring, and the inner flange 2 and the outer flange 3, and on the reducer cover body 1, there is at least one block 6, and the inner flange 2 and the outer flange 3 are connected by at least two reinforcing ribs 4, each of which A connector 5 is provided at the connection between the reinforcing rib 4 and the inner flange 2 or the outer flange 3, and at least two bolt holes 7 are provided on the reducer cover body 1, and the surface of the inner flange 2 is provided with The ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com