Power distribution cabinet

A technology for power distribution cabinets and cabinets, applied in the field of electric power, can solve problems affecting the performance and life of electrical components, hidden dangers of safe operation of equipment, and inability to meet the needs of use, to achieve repeatable adjustment, reduce personnel labor, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

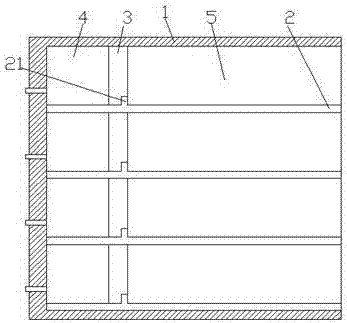

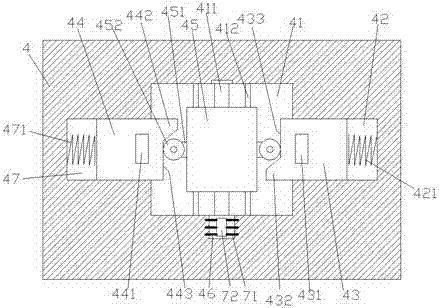

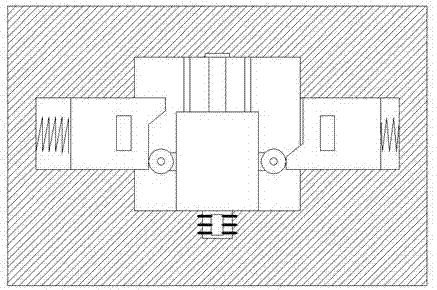

[0020] Such as Figure 1-Figure 7 As shown, a power distribution cabinet of the present invention includes a cabinet body 1, and multiple groups of equidistantly arranged partitions 2 are arranged in the cabinet body 1, and an adjustment device 4 is provided above each partition board 2 And the drawer assembly 5 connected by sliding fit, the air circulation area 3 is provided between the adjustment device 4 and the drawer assembly 5, and the front air duct 12 and the rear air intake duct 11 are provided on the left side of the adjustment device 4 , the adjusting device 4 is provided with a control chamber 41, the two sides of the control chamber 41 are symmetrically provided with a first chute 47 and a second chute 42, and the left and right side walls of the first chute 47 are symmetrically provided with The forward air hole 472 connected with the forward air pipe 12, the left and right side walls of the second chute 42 are symmetrically provided with the rear air inlet hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com