Resistance self-adaptive variable structural cavitator

A cavitator and self-adaptive technology, applied in the direction of hydrodynamic characteristics/hydrostatic characteristics, ships, hulls, etc., can solve the problems of unstable navigation of aircraft, increase ineffective resistance, etc., and achieve the goal of reducing the wet state Drastic changes, improved range, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

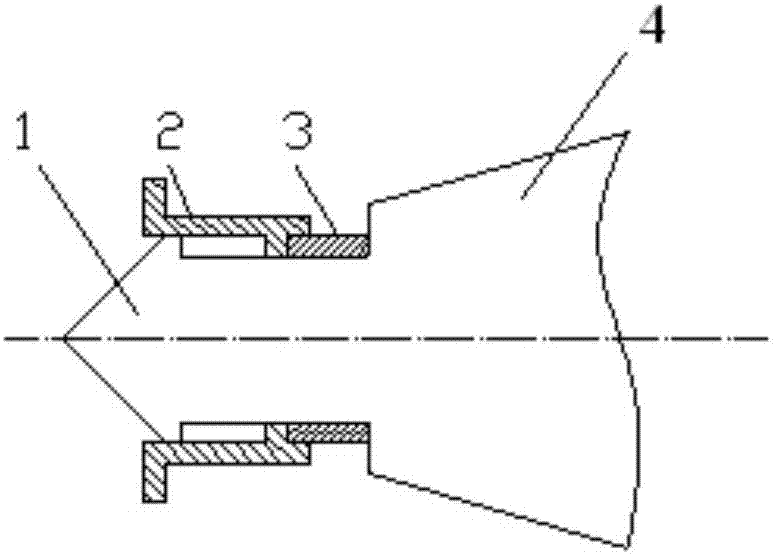

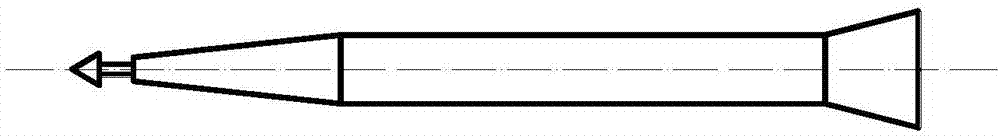

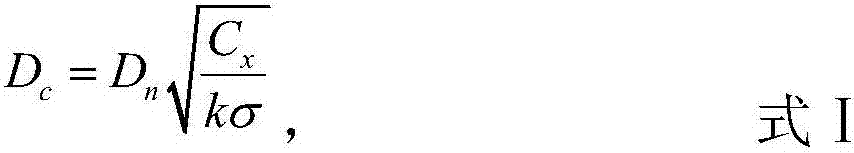

[0060] In this embodiment, a resistance self-adaptive variable structure cavitator, such as figure 1 As shown, it includes a conical cavitator part 1, a movable part 2, and an elastic part 3. The conical cavitator part 1 includes a conical head and a cylindrical tail, and one end surface of the cylindrical tail is connected to the conical head. The bottom surfaces are connected, and the diameter of the cylindrical tail is smaller than the diameter of the bottom surface of the conical head, the elastic part 3 is located at the end of the cylindrical tail away from the conical head, and the movable part 2 is wrapped around the outside of the conical cavitator part 1, And it can move between the elastic part 3 and the conical head, and the movable part 2 and the elastic part 3 adopt a clearance fit with a small gap. When the resistance adaptive variable structure cavitator is used in ordinary supercavitating aircraft, the conical cavitator part 1 and the movable part 2 are made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com