Polypropylene whitening resistant auxiliary agent and application thereof

A technology of polypropylene and whitening additives, which is applied in the field of anti-whitening additives for polypropylene, can solve the problems of polypropylene whitening, etc., and achieve the effects of improving rigidity, good low temperature resistance and high temperature resistance, excellent rigidity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a-1c

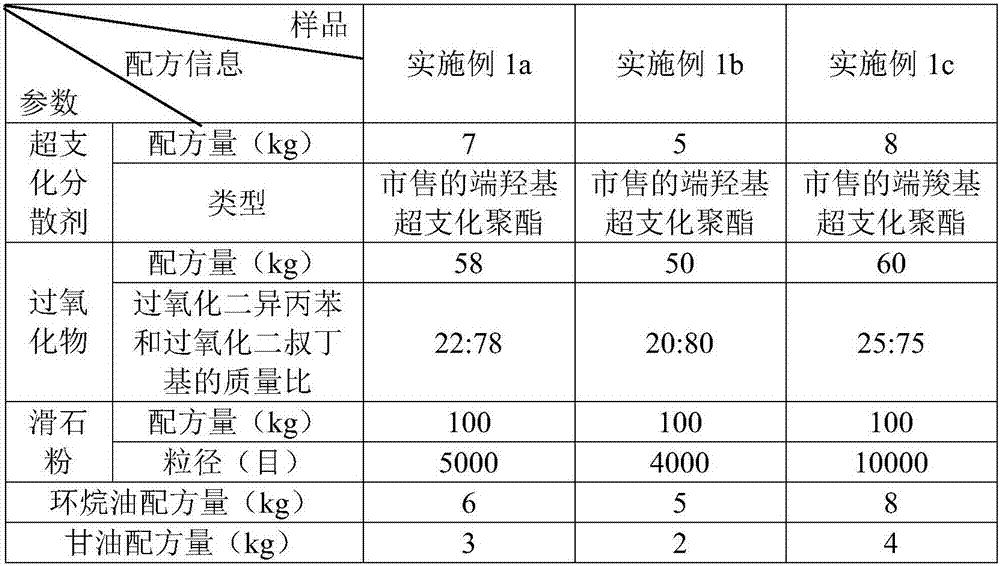

[0021] Examples 1a-1c: an anti-whitening auxiliary agent for polypropylene, which is prepared by mixing the raw materials shown in Table 1.

[0022] Formulation information of table 1 embodiment 1a-1c

[0023]

Embodiment 1d

[0024] Example 1d: an anti-whitening auxiliary agent for polypropylene, which is different from Example 1a in that the hydroxyl-terminated hyperbranched polyester is replaced by commercially available hyperbranched polyethyleneimine.

Embodiment 1e

[0025] Example 1e: an anti-whitening auxiliary agent for polypropylene, which is different from Example 1a in that the mass ratio of dicumyl peroxide and di-tert-butyl peroxide is 10:90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com