Black pigment solution, grey pigment solution and preparation method thereof

A technology of black pigment and pigment liquid, applied in the direction of pigment slurry, etc., can solve the problems of low developability, adhesion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

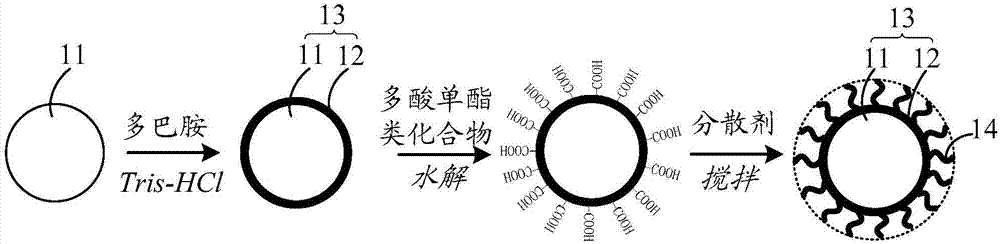

[0054] Correspondingly, the embodiment of the present invention also provides a preparation method of a black pigment liquid, which is schematically shown in figure 1 In particular, the following steps are included:

[0055] S1: Nanoparticles 11 are added to a Tris-HCl (tris(hydroxymethyl)aminomethane) solution of dopamine, stirred to form a layer of polydopamine nanolayers 12 on the surface of nanoparticles 11, centrifuged and washed to obtain black Nanoparticles13.

[0056] In this step, the stirring time may be 15-30 hours, and the stirring temperature may be 10-30°C, preferably 20-25°C.

[0057] Since the preparation methods of nanoparticles of various sizes are very mature, nanoparticles can be obtained commercially, for example, ZnO, TiO 2 and other nanoparticles; or, according to the existing technology, nanoparticles of different sizes can also be obtained by self-made methods, for example: according to 30nm-1000nm SiO can be obtained by hydrolyzing tetraethyl orth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com