Lubricating oil composition and application thereof

A lubricating oil composition and technology of the composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of high oil mist concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0033] For further elaborating the technical means and effects that the present invention takes for reaching the predetermined invention purpose, below in conjunction with preferred embodiment, carry out according to its specific implementation, characteristics and effects of the lubricating oil composition for thread rolling machine proposed in the present invention are described in detail, but are not intended to limit the scope of the invention.

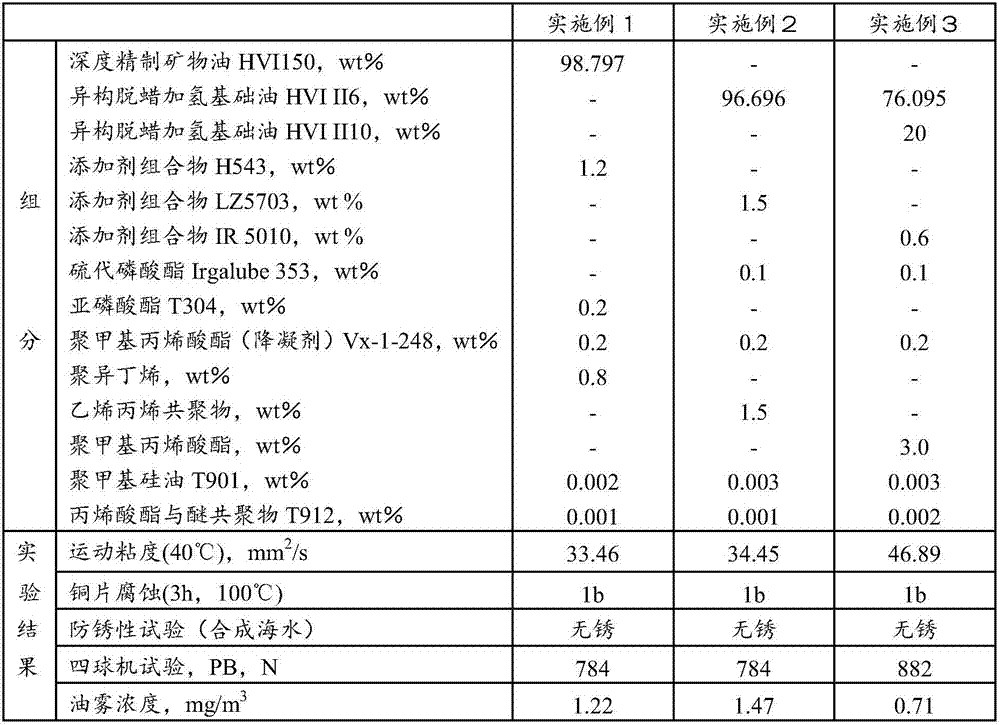

[0034] Add base oil, polymer additives, pour point depressant, heat up to 60°C for heating and stirring, maintain for 2 hours, then lower the temperature to 40°C; then add other ingredients, stir for 2 hours until the mixture is completely dissolved and becomes transparent , to prepare the composition of the present invention. The specific components and product performance of the composition are shown in Table 1.

[0035] Table 1

[0036]

[0037] As shown in the test results of the examples in the table, [Examples 1-3] perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com