Lubrication structure for four-stroke engine

A four-stroke engine and structure technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve problems such as consumption of lubricating oil, poor lubrication, adverse environmental effects, etc., to reduce the concentration of oil mist and prevent consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

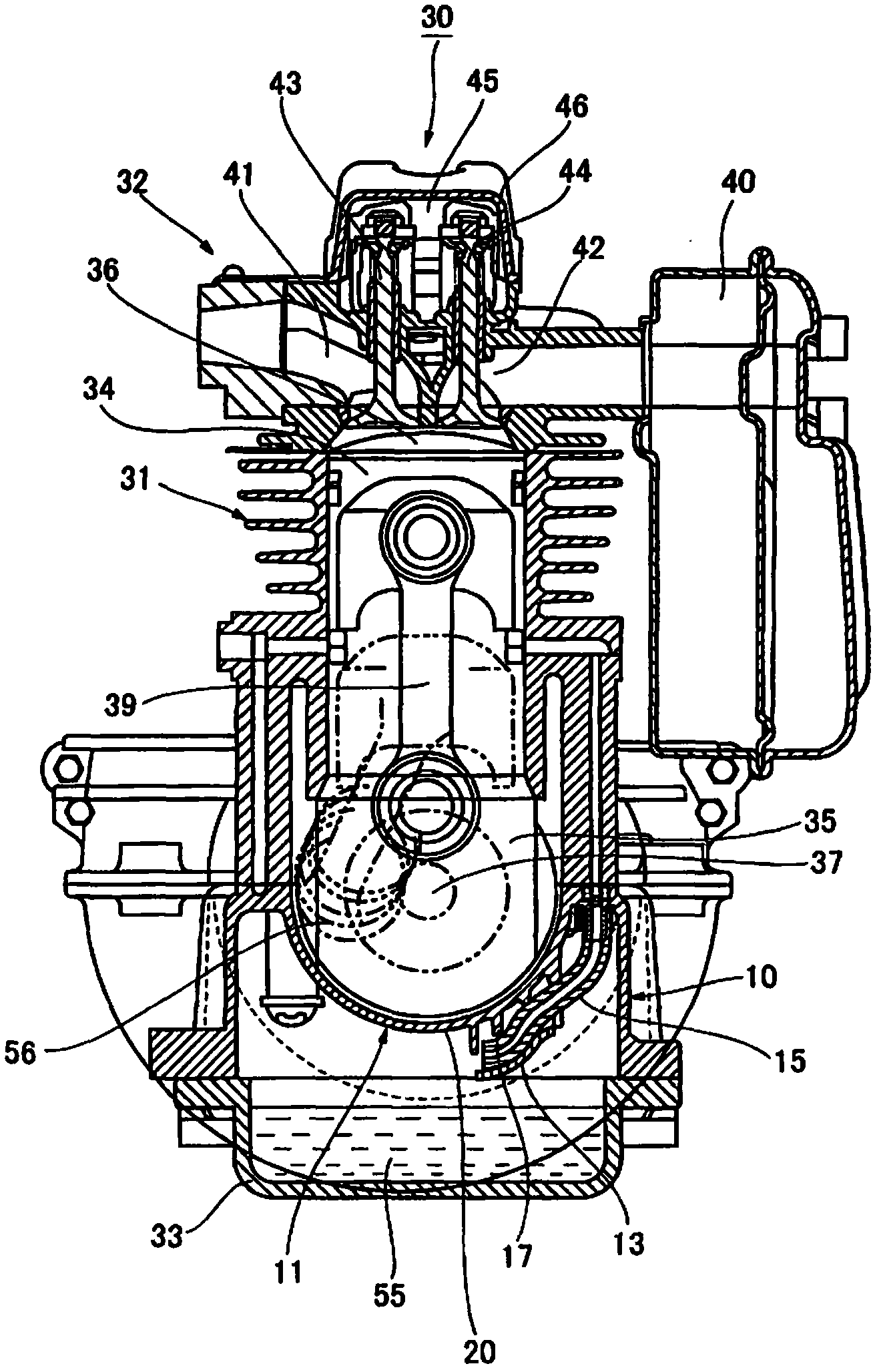

[0046] In the present embodiment, the lubricating structure of the four-stroke engine 30 utilizes the pressure fluctuation in the crank chamber 35 caused by the reciprocating motion of the piston 34 to supply lubricating oil stored in the lubricating oil tank 55 to lubricate the driving parts, and the lubricating oil tank 55 and the lubricating oil tank 55 are connected to The crank chamber 35 is provided independently.

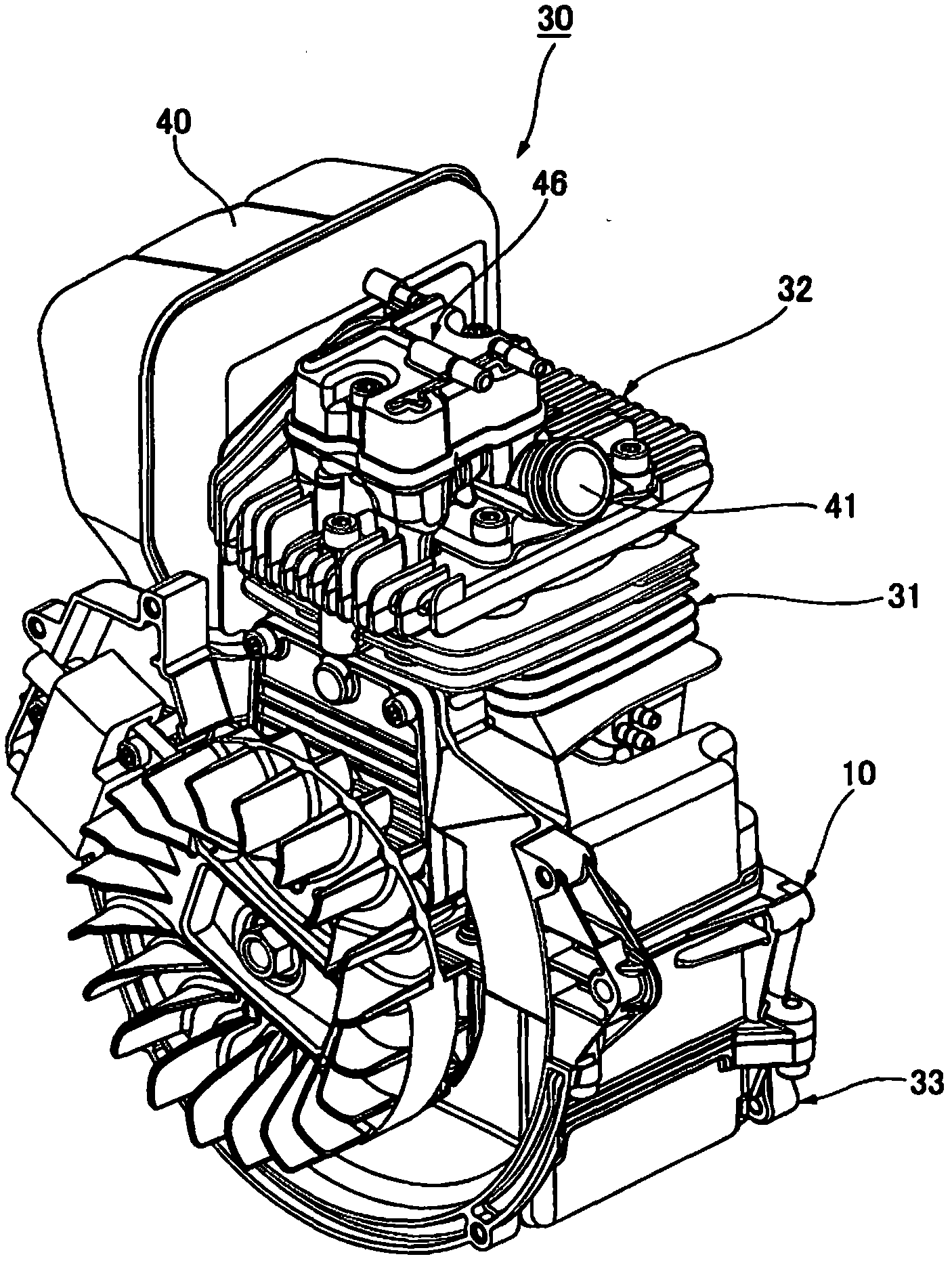

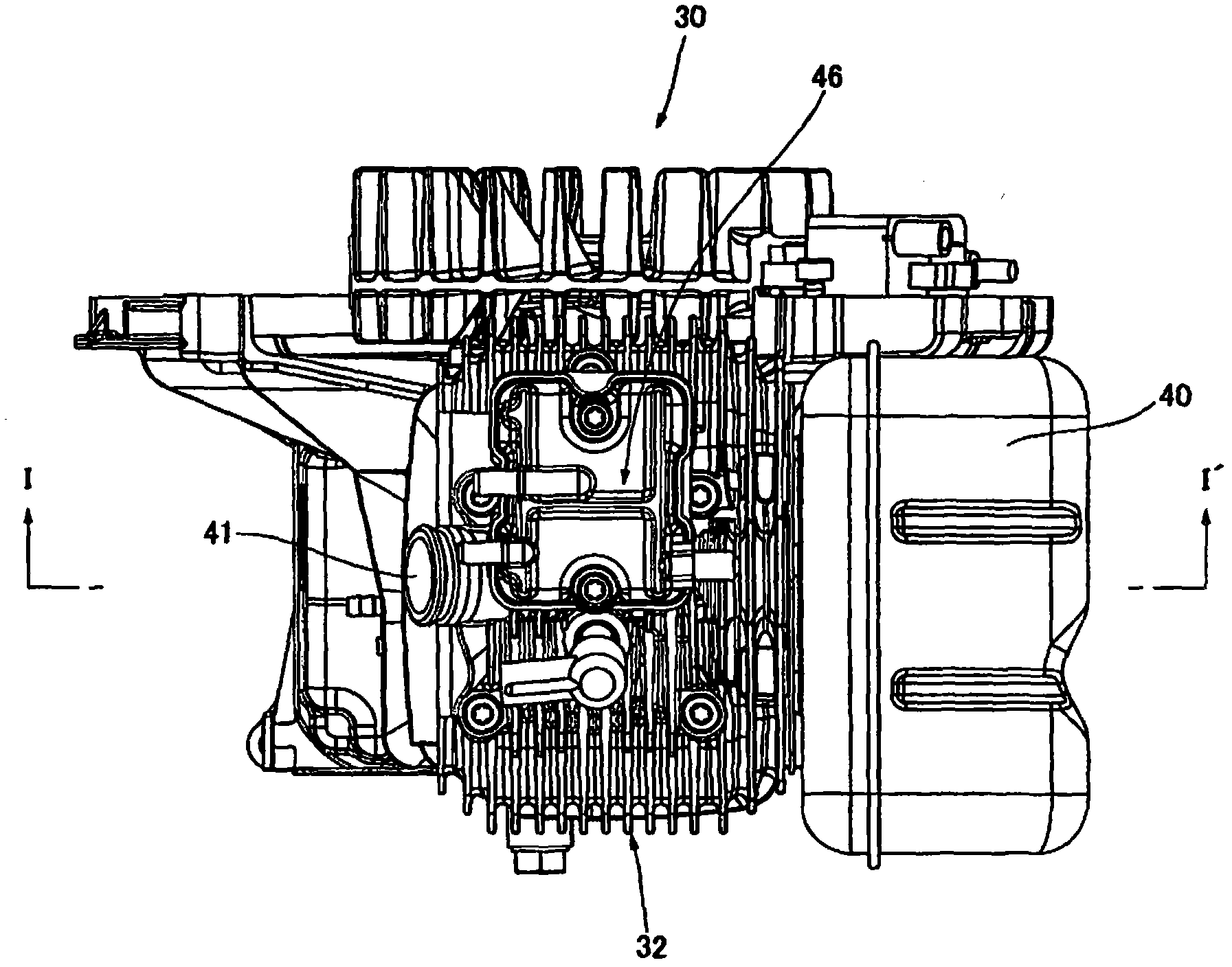

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. First, use Figure 1A , Figure 1B and figure 2 The configuration of the four-stroke engine 30 of the present embodiment will be described. Figure 1A It is a perspective view schematically showing the structure of a four-stroke engine 30 as an embodiment of the present invention, Figure 1B It is a plan view schematically showing the configuration of a four-stroke engine 30 as an embodiment of the present invention, figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com