Coaxial opposite-rotation electric ceiling fan

An electric ceiling fan and coaxial technology, applied in the field of coaxial counter-rotating electric ceiling fans, can solve the problems of low air supply efficiency, increased ceiling fan torque, and large torque, so as to achieve self-balancing, speed up production, and improve air outlet efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

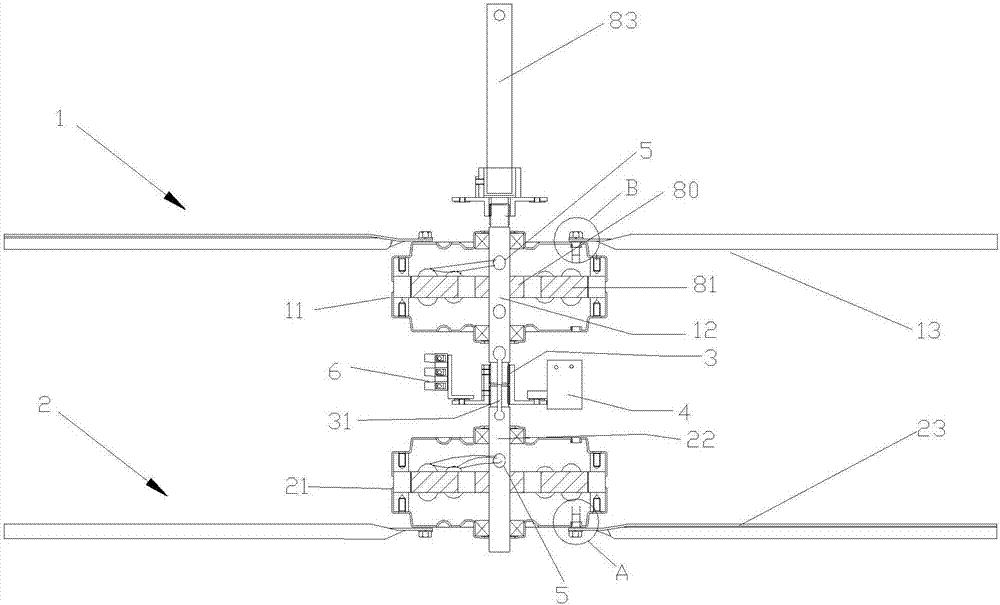

[0066] Such as figure 1 Shown, a kind of coaxial counter-rotating electric ceiling fan, it comprises:

[0067] The first ceiling fan 1 includes: a first motor 11 , a first shaft 12 passing through the stator 80 of the first motor 11 , and a first fan blade 13 connected with the rotor 81 of the first motor 11 ;

[0068] The second ceiling fan 2 includes: a second motor 21 , a second shaft 22 passing through the stator 80 of the second motor 21 , and a second fan blade 23 connected with the rotor 81 of the second motor 21 ;

[0069] Both the first motor 11 and the second motor 21 are external rotor motors, and the rotation directions of the first motor 11 and the second motor 21 are opposite;

[0070]the first crankshaft and the second crankshaft are on the same vertical line;

[0071] A shaft coupling 3, which is used to connect the pre-installed first ceiling fan 1 and the second ceiling fan 2 into one body, and the first shaft 12 and the second shaft 22 pass through the s...

Embodiment 2

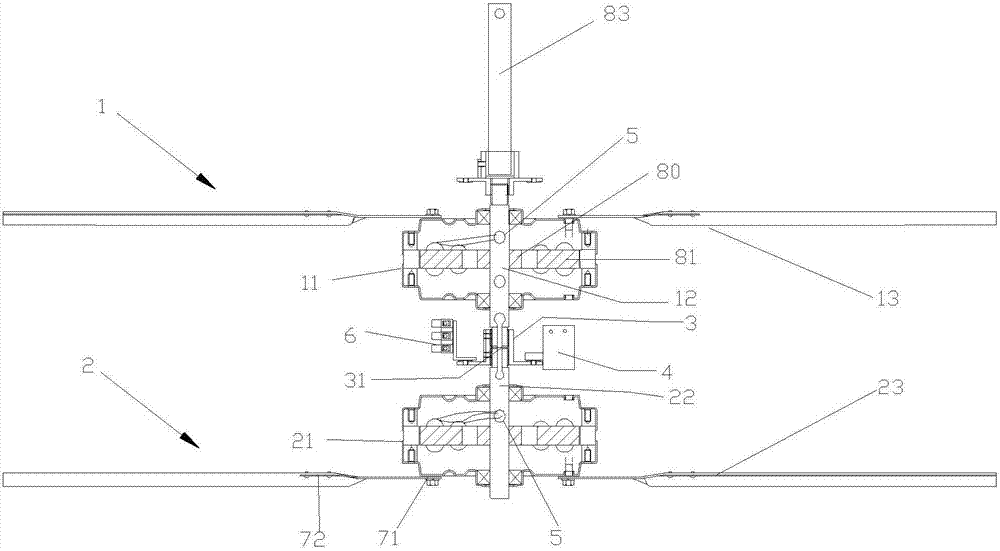

[0090] This embodiment is basically the same as above-mentioned embodiment 1, and its difference is:

[0091] Such as figure 2 As shown, the coaxial counter-rotating electric ceiling fan is also provided with a leaf fork 7, and the leaf fork 7 includes a motor installation part 71 and a fan blade installation part 72;

[0092] The motor installation part 71 is connected to the first motor 11 or the second motor 21, and the fan blade installation part 72 is connected to the first fan blade 13 or the second fan blade 23;

[0093] The first fan blade 13 is connected to the first motor 11 through the blade fork 7;

[0094] The second fan blade 23 is connected to the second motor 21 through the blade fork 7 .

Embodiment 3

[0096] This embodiment is basically the same as above-mentioned embodiment 1, and its difference is:

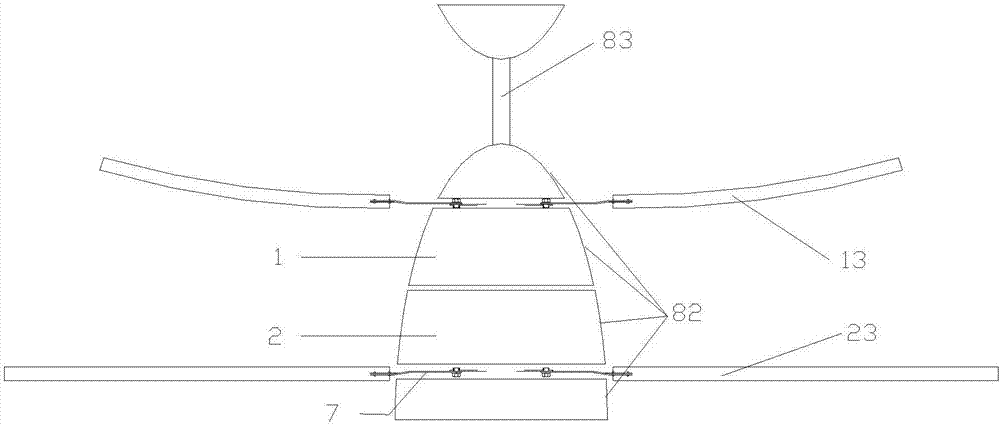

[0097] Such as image 3 As shown, the size and length of the first fan blade 13 and the second fan blade 23 are the same or different;

[0098] The first fan blade 13 and the second fan blade 23 are straight blades or warped blades;

[0099] The blade root of the first fan blade 13 and the second fan blade 23 is wider than the blade tip or the blade tip is wider than the blade root;

[0100] The inclination angles of the first fan blade 13 and the second fan blade 23 are each arbitrarily selected;

[0101] The number of the first fan blade 13 and the second fan blade 23 is composed of 2-10 pieces;

[0102] The first fan blade 13 and the second fan blade 23 are made of plastic or metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com