Gap type reciprocating swing rod mechanism

A rod mechanism and gap-type technology, which is applied in the field of gap-type reciprocating swing rod mechanism, can solve the problems that cannot solve the swing requirements of special applications, and it is difficult to realize intermittent partition driving, etc., and achieve the effect of various adjustment methods and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

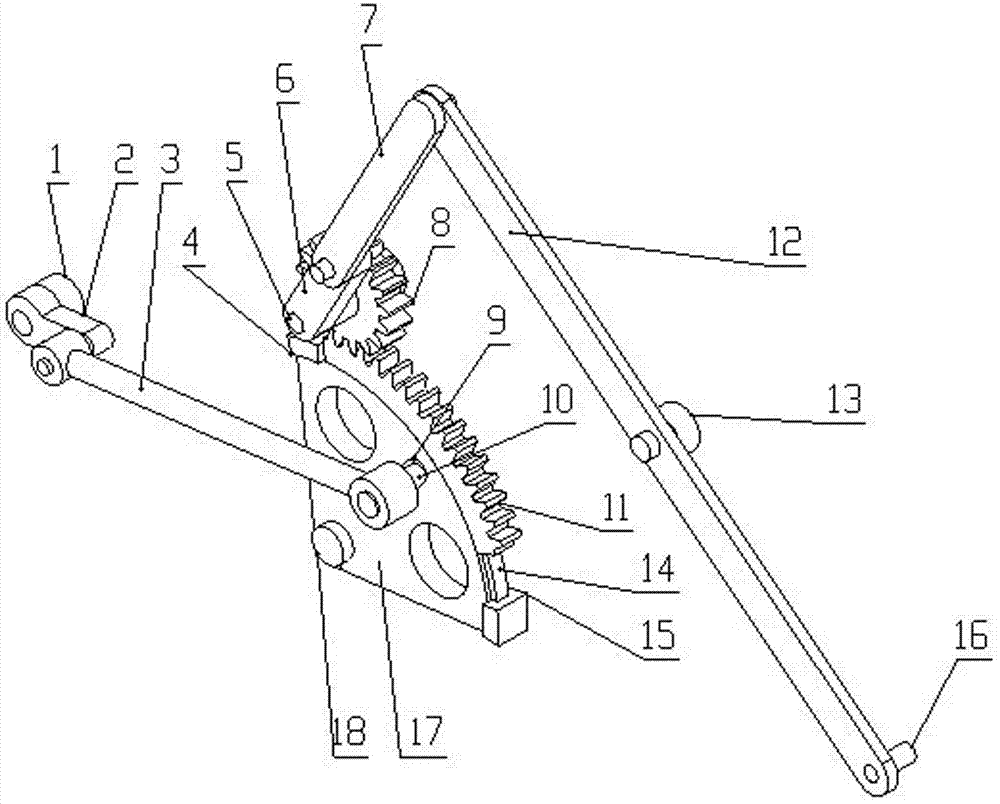

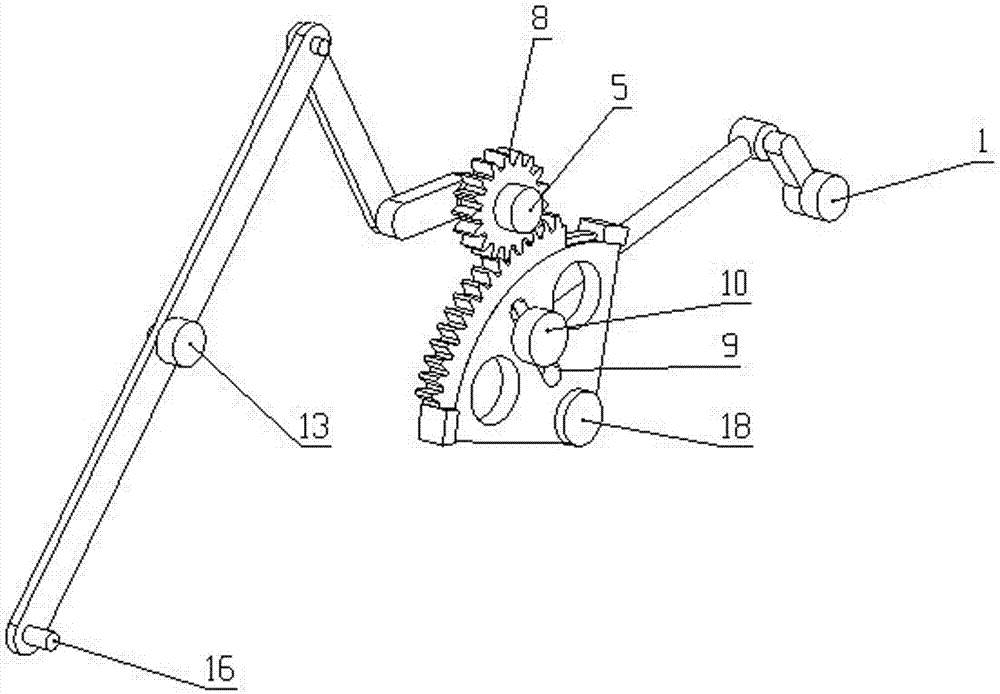

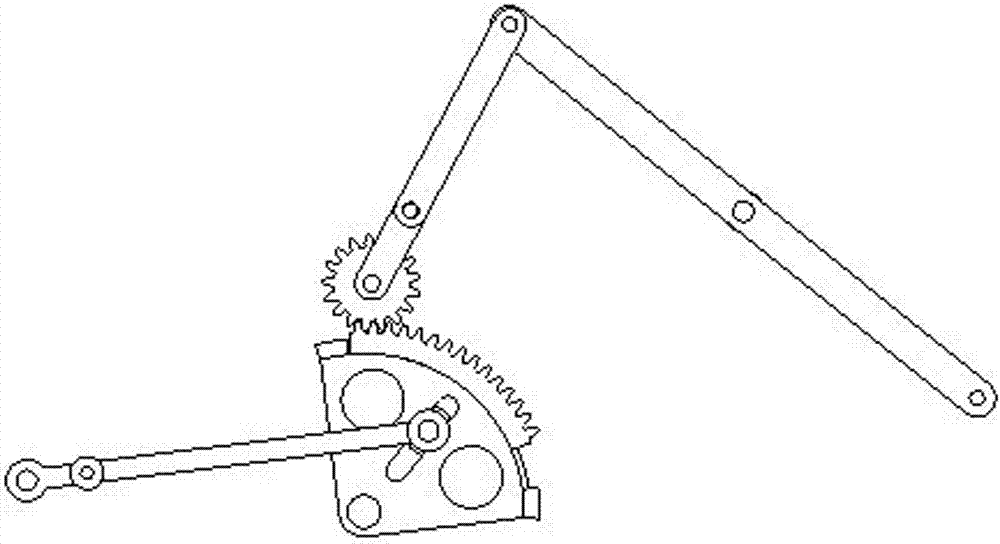

[0017] Such as Figure 1-Figure 4 As shown, an embodiment of a gap type reciprocating swing link mechanism of the present invention is mainly composed of a crank shaft 1, a crank 2, a connecting rod 3, a first baffle plate 4, a driven crank shaft 5, a driven crank 6, and a driven connecting rod. 7. Driven gear 8, U-shaped groove 9, connecting rod shaft 10, sliding gear 11, swing rod 12, swing rod shaft 13, sliding guide groove 14, second baffle plate 15, swing rod drive shaft 16, fan-shaped pendulum block 17, fan-shaped pendulum block shaft 18 etc. constitute. Wherein: the crank shaft 1 drives the crank 2 to drive the connecting rod 3 to perform reciprocating motion, the connecting rod 3 and the fan-shaped pendulum block 17 are hingedly connected through the connecting rod shaft 10, and the connecting rod shaft 10 is installed in the U-shaped groove 9 on the fan-shaped pendulum block 17, It is fixed with bolts and can be adjusted in different positions in due course. A slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com