Digital holographic detection system of wafer laser ultrasonic field, and method thereof

A digital holography and detection method technology, applied in the field of optical systems, can solve problems such as low resolution and X-ray inability to locate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

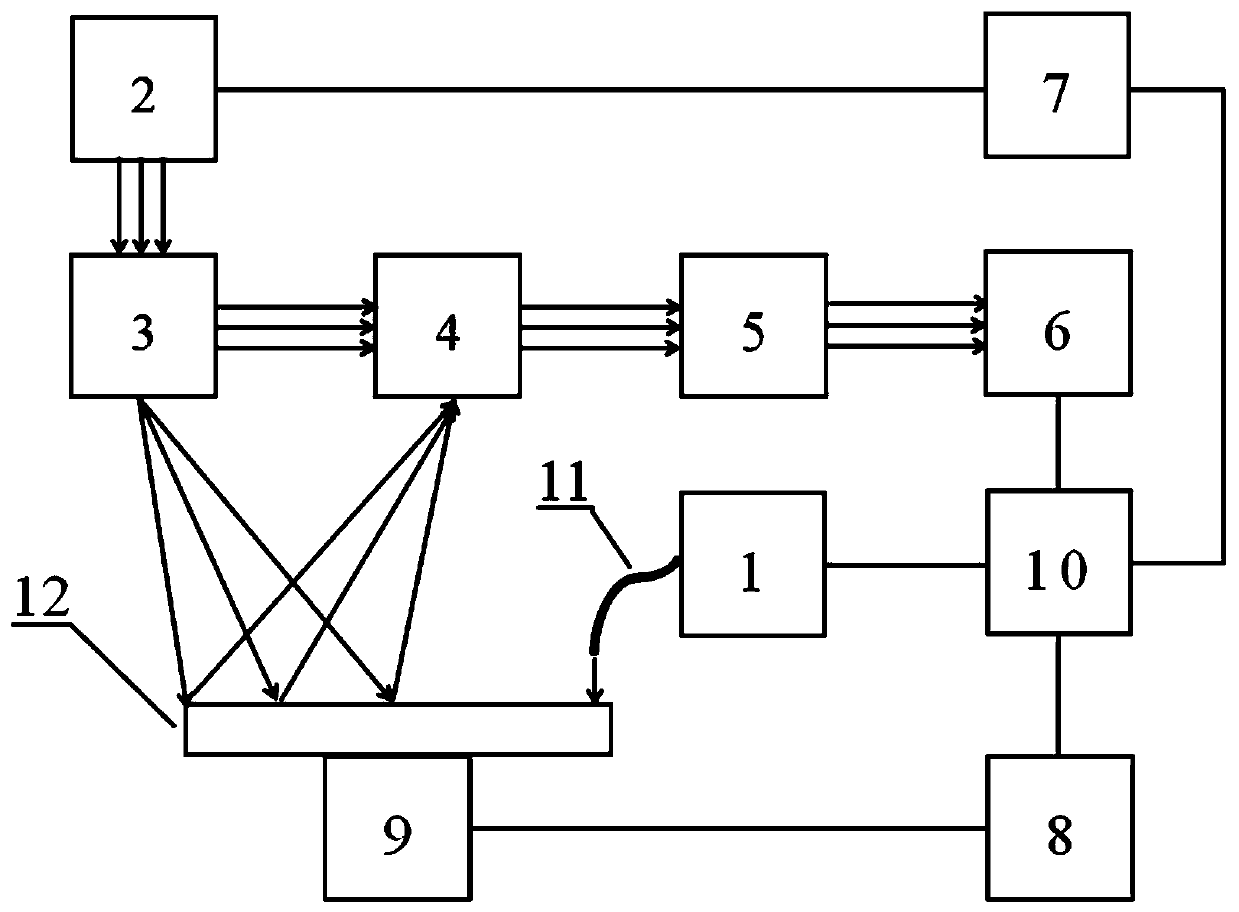

[0056] combined with figure 1 , a digital holographic inspection system for wafer laser ultrasonic field, including nanosecond pulse excitation light source 1, nanosecond pulse detection light source 2, incident optical unit 3, collection optical path unit 4, microscopic objective lens 5, photoelectric detector 6, delay Time unit 7, motor controller 8, precision mobile stage 9, computer 10, optical fiber 11, wafer 12; The incident optical unit 3 is placed between the nanosecond pulse detection light source 2 and the collection optical path unit 4; The objective lens 5 is placed between the collection optical path unit 4 and the photodetector 6; the collection optical path unit 4 is placed between the incident optical unit 3 and the microscope objective lens 5; the incident optical unit 3 and the collection optical path unit 4 are placed in the crystal Above the upper surface of the circle 12; the nanosecond pulse excitation light source 1 is mechanically connected to the opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com