A Thyristor Press-fit Structure for Modular Multilevel Voltage Source Converter

A voltage source converter, modular multi-level technology, applied in the direction of electric solid devices, output power conversion devices, circuits, etc., to achieve the effect of easy maintenance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with example the present invention is described in detail.

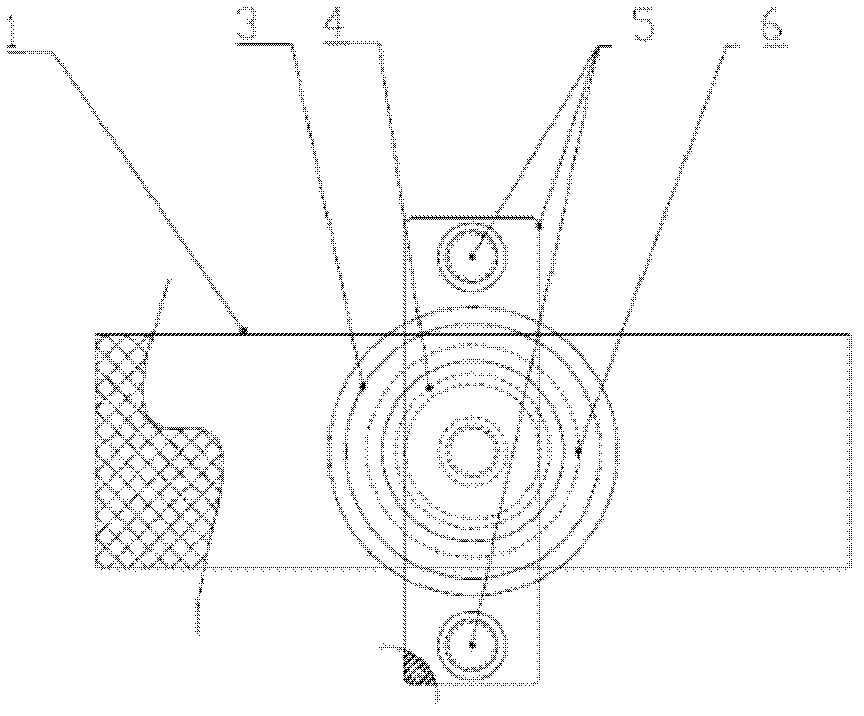

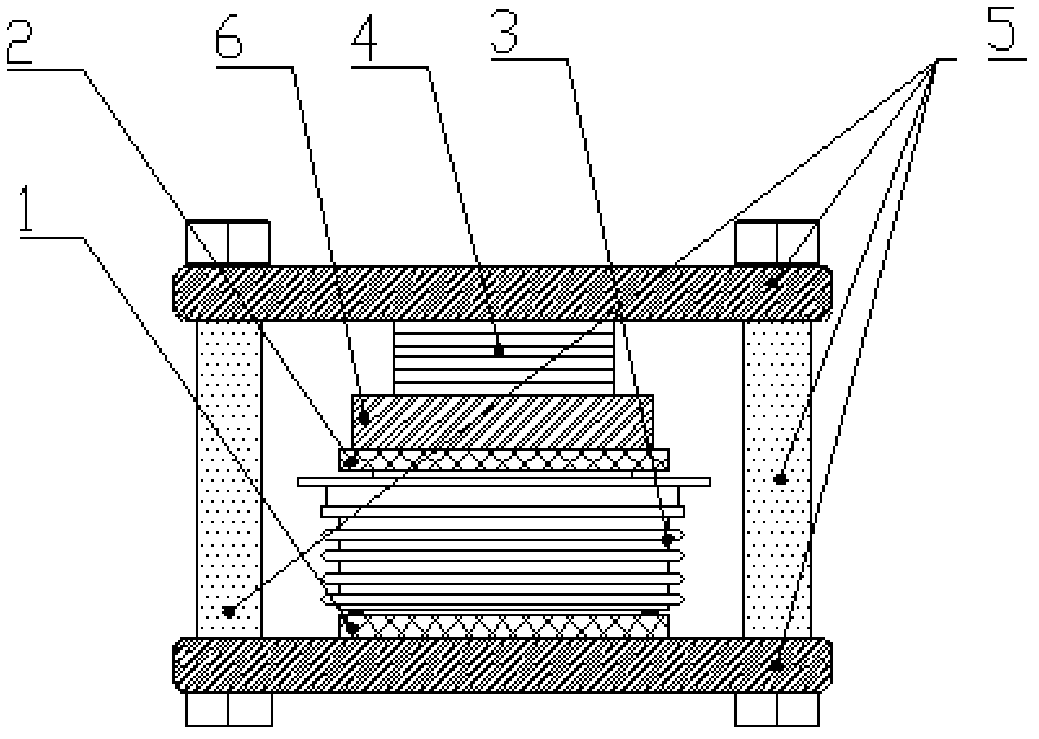

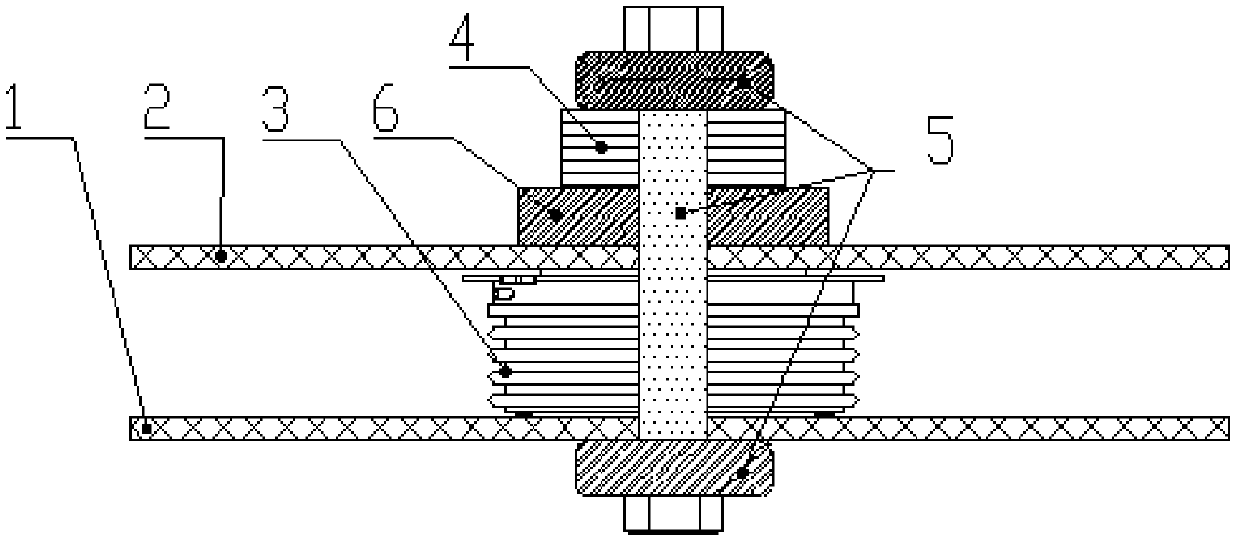

[0035] A thyristor press-fit structure for a modular multi-level voltage source converter according to the present invention, its front view is as follows figure 1 As shown, the left view is as figure 2 As shown, the top view is as image 3 As shown, the press-fit frame 5 is mainly made of steel or high-strength insulating material, and its function is to fix the disc spring 4, the insulator 6, the negative busbar 2, the thyristor 3 and the positive busbar 1, and the disc spring 4, the insulator 6, the negative busbar Row 2, thyristor 3 and main busbar 1 are placed coaxially, and the press-fitting frame 5 exerts top pressure on the thyristor through two symmetrical bolts and two flat plates arranged up and down to meet the requirements of the press-fitting force of thyristor 3, among which the high-strength Insulating materials include rigid materials such as glass fiber reinforced plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com