Packaging box drop test clamping device

A technology of drop test and clamping device, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., which can solve problems such as unsafety and increased test difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

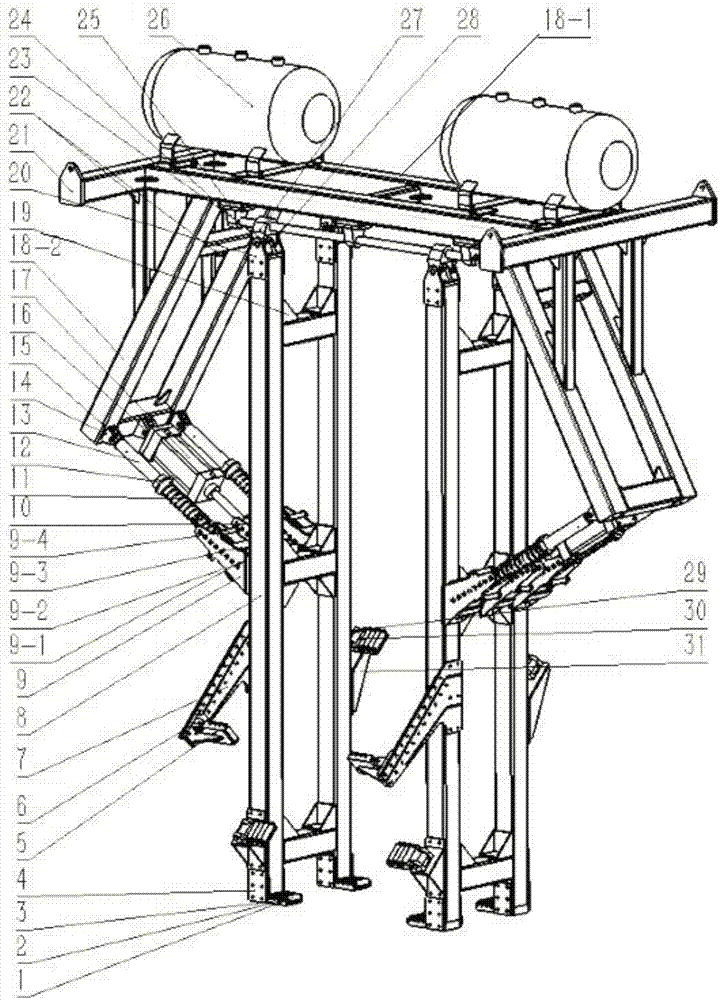

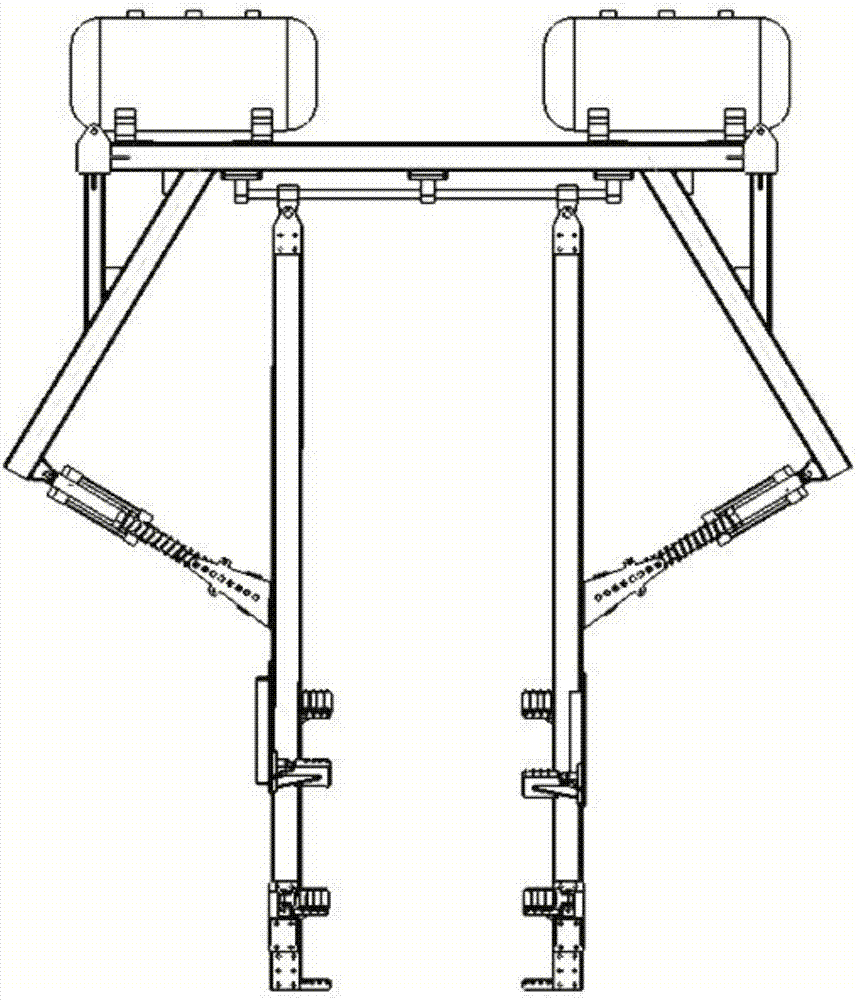

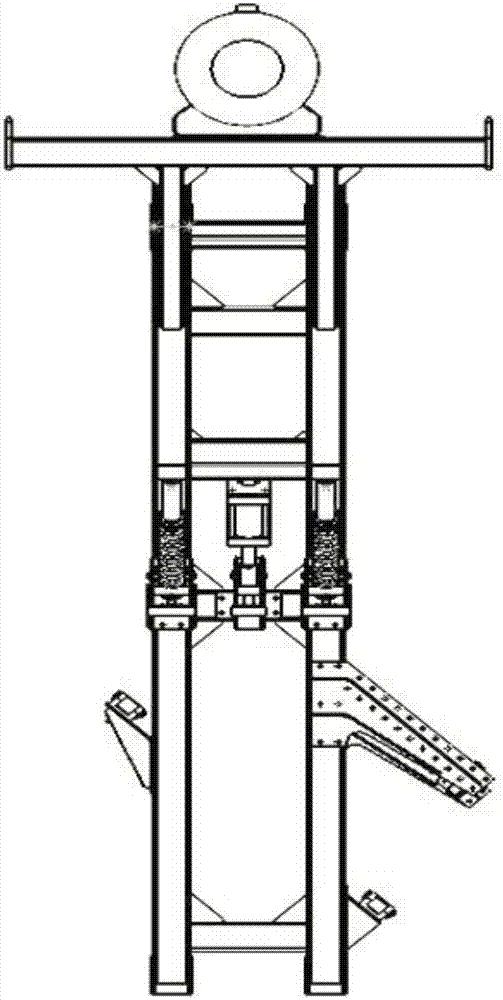

[0014] combine Figure 1 to Figure 4 , a packing box drop test clamping device, the device is symmetrically designed, including the frame body installation part, the pre-tightening spring clamping system part, the adjustment connection bracket part, the inclination angle clamping part, the swing arm part, the horizontal support assembly part, etc. six parts.

[0015] The frame installation part includes the package box hoisting frame with an inclination of 18 inclinations, the cylinder installation hinges with an inclination of 16 inclinations, the spring support cylinder hinges with an inclination of 14 inclinations, the gas storage tank with an inclination of 26 inclinations, the lateral adjustment guide rod with an inclination of 28 inclinations, and the frame hook The inclination angle of the welding plate is 21 inclination angles, the inclination angle of the conductor positioning welding plate is 25 inclination angles, the inclination angle of the conductor mounting brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com