Device and method for wheeltrack friction fatigue test

A friction fatigue, experimental device technology, used in measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

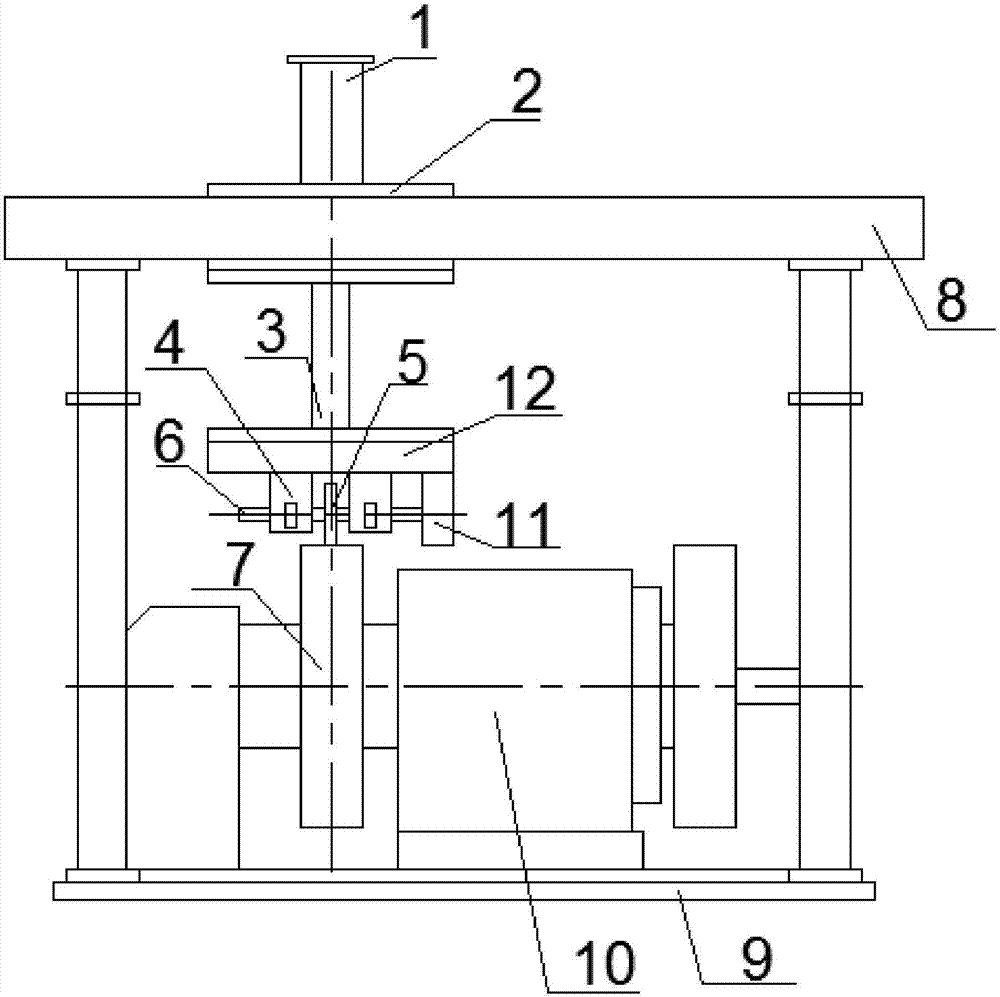

[0023] figure 1 Shown, a kind of specific embodiment of the method of the present invention is: a kind of wheel-rail friction fatigue experiment device, comprises the DC motor 10 that is installed on the support 9, the support 9, the output shaft of DC motor 10 and the big wheel of simulation rail 7 are connected, the hydraulic cylinder 1 is installed on the crossbeam 8 of the machine base 9, the end of the piston rod 3 protruding downward from the hydraulic cylinder 1 is connected with the small wheel mounting seat 12, and the small wheel 5 simulating a high-speed wheel is installed on the On the steamboat mount 12; It is characterized in that:

[0024] A magnetic powder brake 11 is installed on the small wheel mount 12, and one end of the shaft of the small wheel 5 passes through the bearing 4 and is connected with the output shaft of the magnetic powder brake 11;

[0025] The rim of the small wheel 5 is arc-shaped along the width direction, and the rim of the big wheel 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com