A traceability circuit and method for large capacitance

A technology of large capacitors and capacitors, which is applied in the field of portable DC high current meters, can solve the problems of few calibration methods for large capacitors, small impedance of large capacitors, and low measurement indicators, and achieve the effect of solving inaccurate measurement of small voltage ratios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

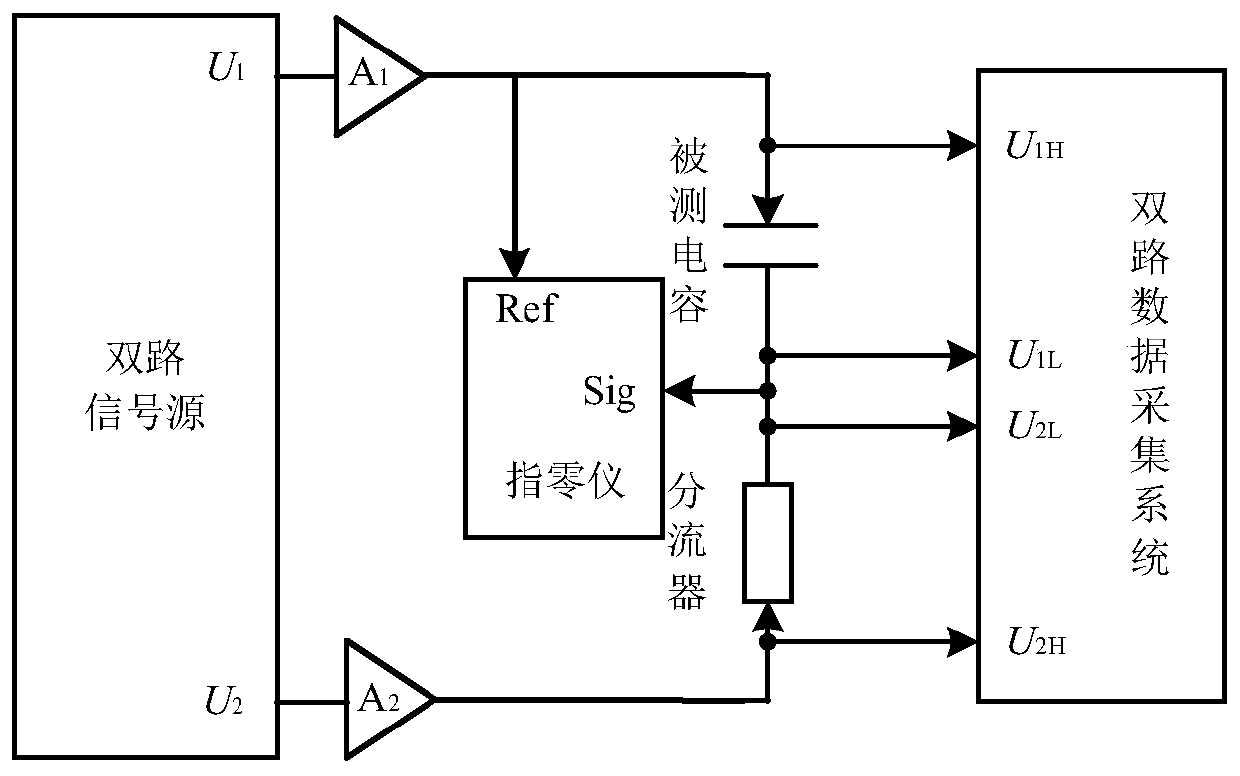

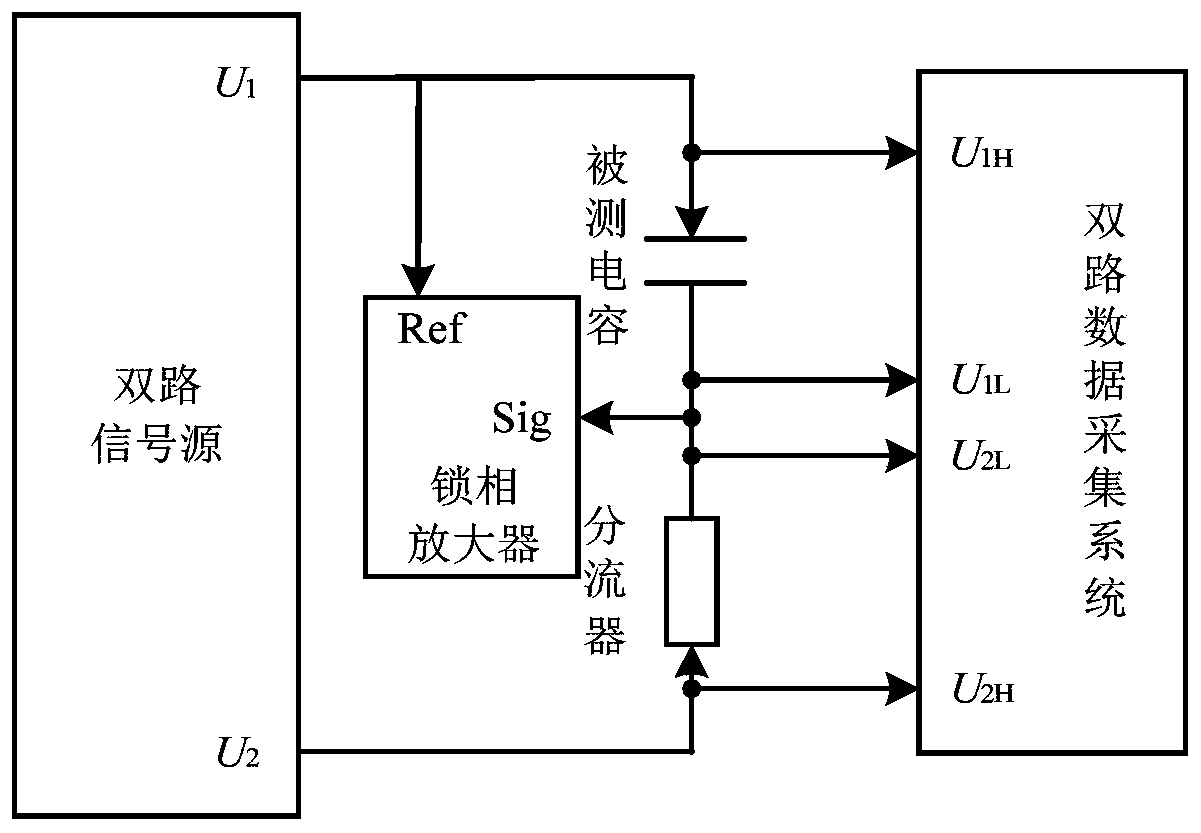

[0018] see figure 1 , shows the schematic diagram of the large capacitance traceability method of the present invention, wherein the circuit dual signal source U 1 , U 2 , means zero instrument, shunt and dual-channel data acquisition system, wherein the first signal source U of the dual-channel signal source 1 Connected first drive and isolation circuit A 1 , and the second signal source U 2 Connected second drive and isolation circuit A 2 , the first drive and isolation circuit A 1 and the second drive and isolation circuit A 2 The output terminals are respectively connected to one end of the measured capacitor and the shunt, and the other end of the measured capacitor and the other end of the shunt are connected to the signal end of the zero indicator; the first drive and isolation circuit A 1 Or the second drive and isolation circuit A 2 The output terminal is also connected to the reference terminal of the zero-pointing instrument; wherein, the two channels of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com