High-density optical fiber connector

A fiber optic connector, high-density technology, applied in the direction of light guides, optics, instruments, etc., can solve the problem that the connection density cannot be increased, and achieve the effects of low optical connection loss, high channel density, and strong environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

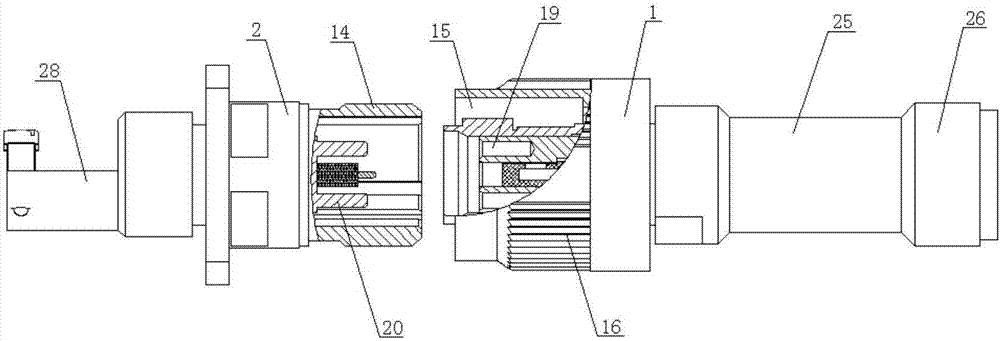

[0025] like figure 1 As shown, a high-density optical fiber connector of the present invention includes a plug 1 and a socket 2, the plug 1 and the socket 2 are mated and connected, and two sections of optical fiber are respectively connected to the plug 1 and the socket 2. The opposite end surfaces of the plug 1 and the socket 2 are respectively provided with identification bits 4, which is convenient for unifying the optical channel sequence and installation and debugging.

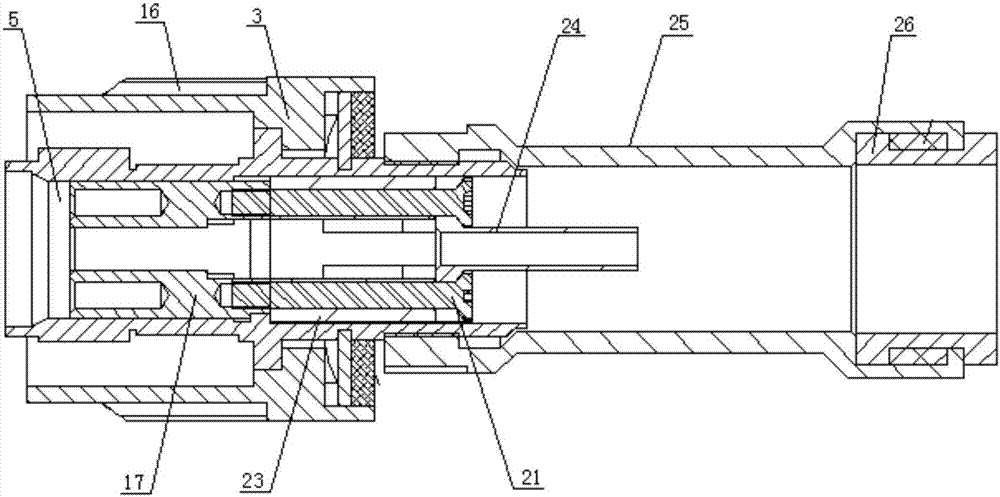

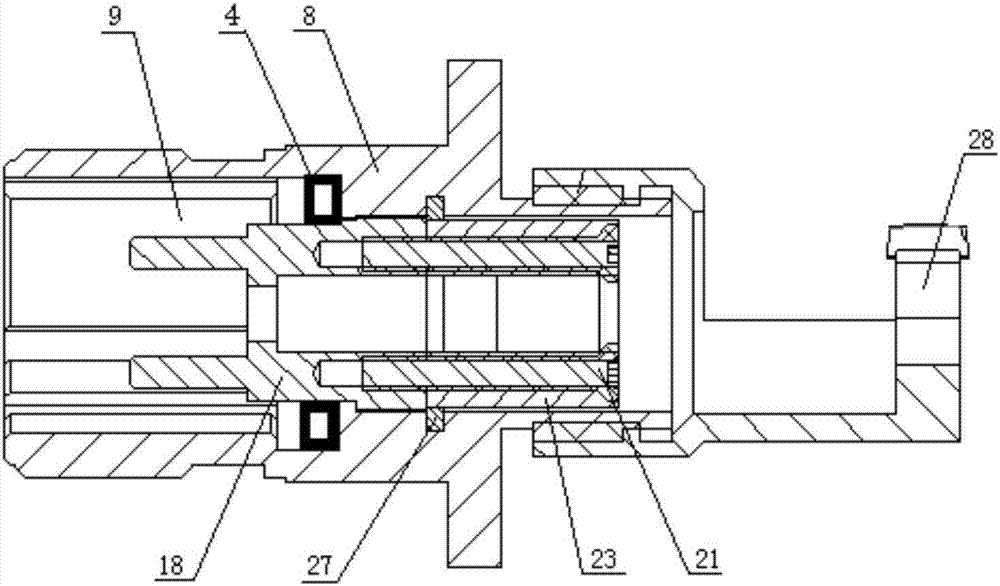

[0026] like Figure 2-9 As shown, the plug 1 includes a shell I3, and the shell I3 is the plug shell of the J599III connector. The shell I3 is provided with a positioning groove I5, and the light array cathode ferrule 6 is installed in the positioning groove I5, and the light array cathode ferrule 6 is installed in the positioning groove I5 through the ferrule package I17,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap