Manufacturing method of crystalline silicon battery piece

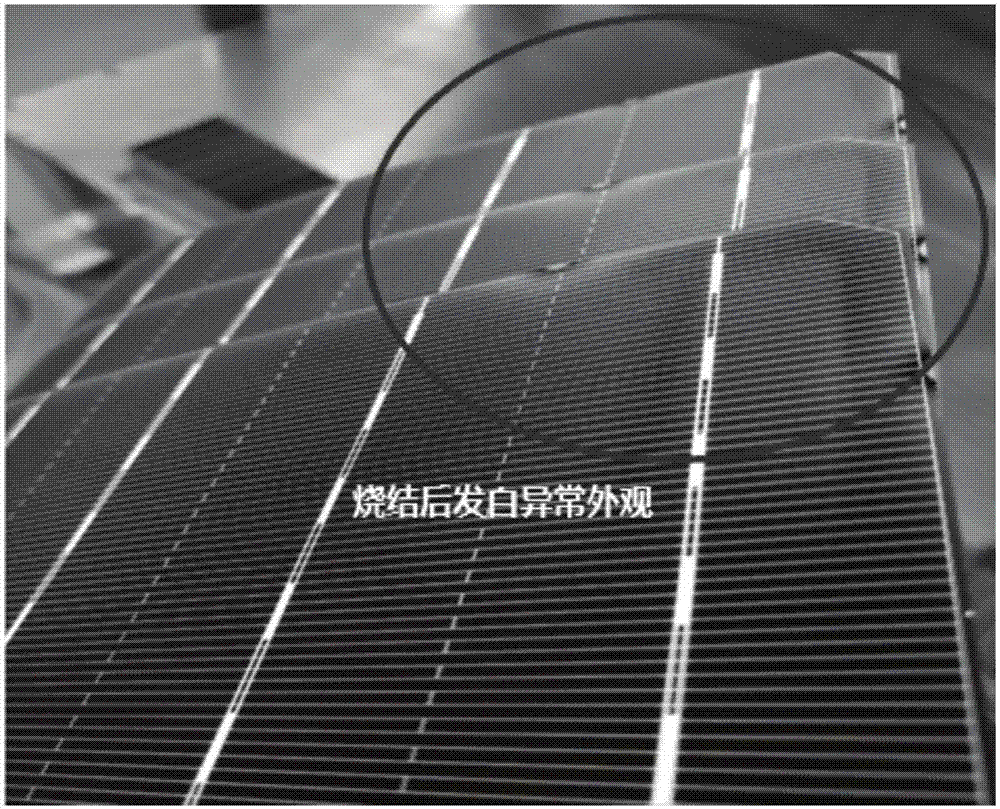

A manufacturing method and technology of crystalline silicon cells, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of enterprise economic loss, appearance identification, and trouble shooting of manufacturing enterprises, so as to solve the problems of whitening after sintering, The effect of anti-PID function improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

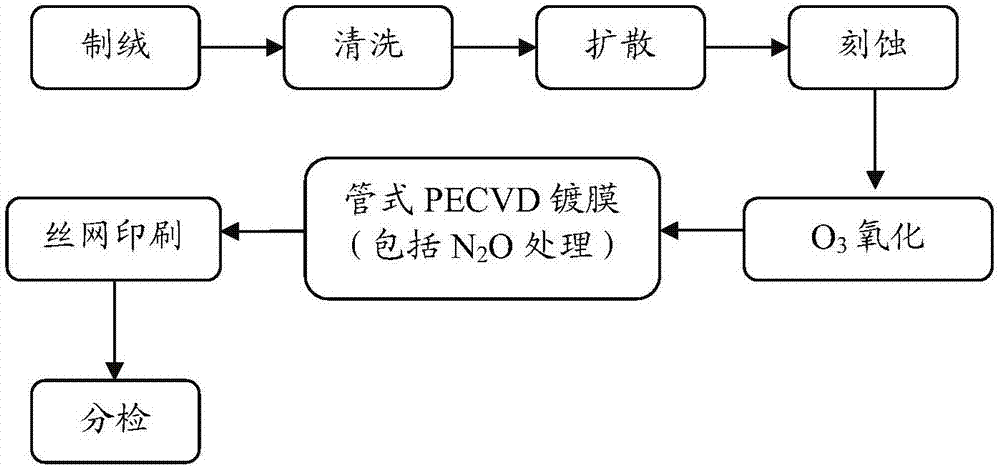

[0020] The manufacturing method of the crystalline silicon battery sheet of the present invention comprises the tubular PECVD coating step, and the described tubular PECVD coating step comprises carrying out N in the tubular PECVD. 2 O treatment and at least two silicon nitride layer coatings, said N after the first silicon nitride layer coating 2 O treatment, the crystalline silicon battery sheet has no whitening phenomenon after sintering and has anti-PID performance.

[0021] In a specific embodiment provided by the present invention, said N 2 O treatment to purge the silicon nitride layer to form N 2 Oxide layer.

[0022] In a specific embodiment provided by the present invention, said N 2 The process parameters in the O treatment include: power 5000-6500w, pressure 1600-2500mtorr, flow rate 3000-60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com