Novel negative electrode of lithium-ion power battery and lithium-ion power battery

A power battery, lithium ion technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve problems such as disadvantage, electrolyte infiltration, and difficulty in temperature rise of negative electrode performance, and achieve improved safety, product quality and market. Competitiveness, the effect of reducing the DC internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

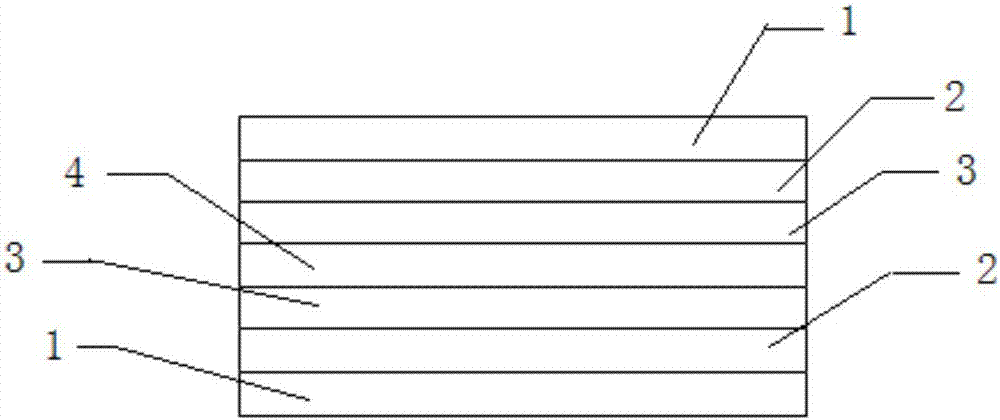

Image

Examples

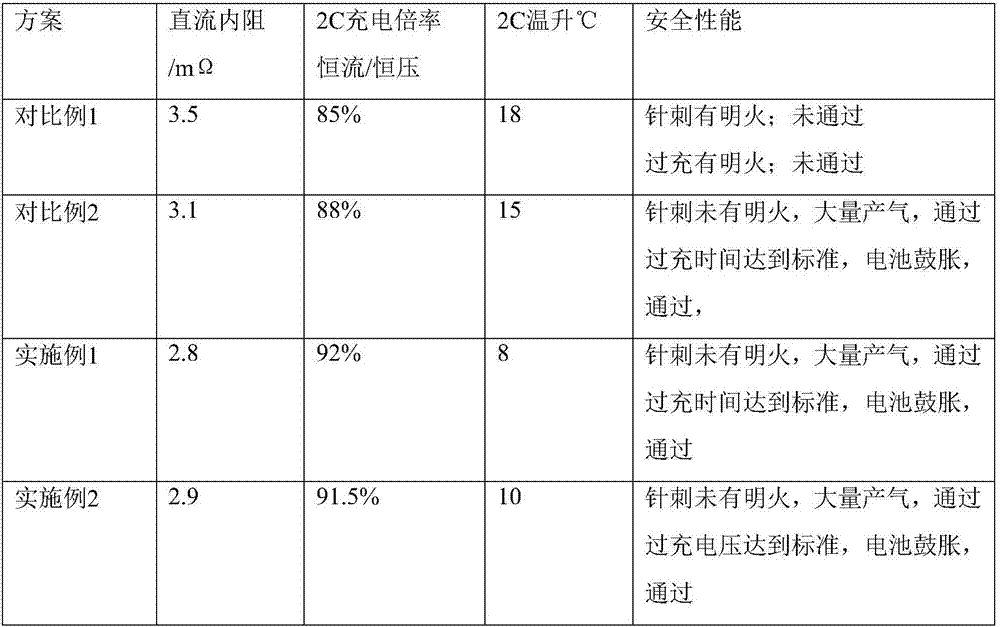

Embodiment 1

[0026] A novel lithium ion power battery negative pole, its preparation method is as follows,

[0027] 1) Coating a layer of conductive coating on the lithium-ion battery negative electrode current collector, the conductive coating includes the following raw materials in parts by weight; the conductive material is 8 parts of mesophase carbon microspheres, the dispersion liquid is 90 parts of water and ethanol, and The weight ratio of water and ethanol is 6:4, and the binder is 2 parts of polyamide. After high-speed dispersion and ultrasonic vibration, a conductive paste with a solid content of 8% is obtained, and then coated on the copper foil by an anilox roller. The thickness is double-sided thickness (the sum of the thickness of the conductive coating on both sides) 2μm, and it is ready to use after drying;

[0028] 2) The negative electrode slurry produced by the normal homogenization process is coated on the negative electrode current collector with a conductive coating. ...

Embodiment 2

[0033] A novel lithium ion power battery negative pole, its preparation method is as follows,

[0034] 1) Coating a layer of conductive coating on the lithium-ion battery negative electrode current collector, the slurry of the conductive coating includes the following components by weight, the conductive material is 10 parts of multilayer graphene, and the dispersion liquid is water and tert-butyl 85 parts of alcohol, and the weight ratio of the two is 7:3, and the binder is 2 parts of polyamide. After high-speed dispersion and ultrasonic oscillation (oscillation frequency 50KHz), a conductive paste with a solid content of 8% is obtained, and then passed through the net The textured roller is coated on the copper foil with a thickness of 2 μm on both sides, and it is ready for use after drying;

[0035] 2) The negative electrode slurry produced by the normal homogenization process is coated on the negative electrode current collector with a conductive coating. The relevant coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com