Collagen/bacterial cellulose composite membrane dressing and preparation method thereof

A technology of bacterial cellulose film and bacterial cellulose, which is applied in the field of medical biomaterials, can solve the problems of reduced biological safety, reduced film performance, and loss of biological activity of dressings, and achieves improved biological safety, improved retention stability, collagen The effect of increased import volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] One aspect of the present invention provides a kind of preparation method of collagen / bacterial cellulose composite film dressing, and this preparation method comprises:

[0030] (1) Purify the natural bacterial cellulose membrane;

[0031] (2) The purified aqueous bacterial cellulose membrane is directly vacuum freeze-dried without pre-freezing treatment to obtain a macroporous bacterial cellulose membrane;

[0032] (3) Under the condition of less than 20°C, the natural collagen is dissolved with aqueous acetic acid to obtain a collagen solution;

[0033] (4) immersing the macroporous bacterial cellulose membrane in the collagen solution, and introducing collagen into the bacterial cellulose membrane under vacuum conditions;

[0034] (5) placing the collagen-introduced bacterial cellulose membrane into a phosphate buffer solution with a pH of 6.0-8.0, and performing fibrillation treatment to obtain a collagen fibrillated composite membrane;

[0035] (6) directly vacu...

Embodiment 1

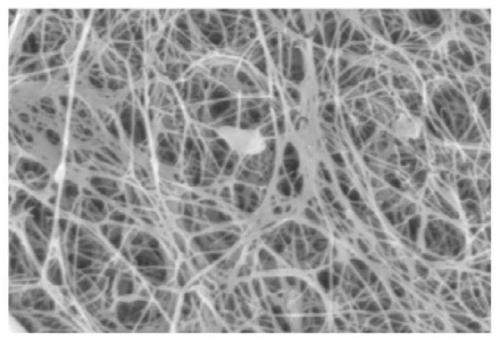

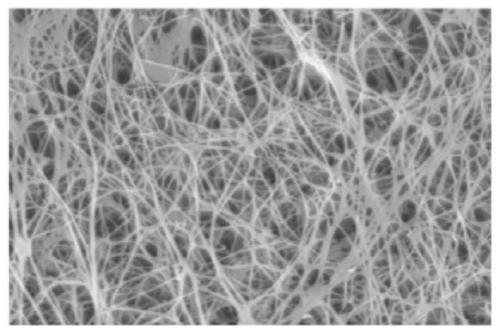

[0051] Place the bacterial cellulose membrane in a beaker and soak it in enough ultrapure water for 24 hours to make it fully absorb water and swell. Then boil with 0.1mol / L NaOH solution for 30min, wash with ultrapure water until neutral, then transfer the bacterial cellulose membrane to 0.05mol / L acetic acid solution for soaking for 24h, wash with ultrapure water until neutral for later use. The purified aqueous bacterial cellulose membrane is placed in a freeze dryer, vacuumed, and the absolute pressure of the system is reduced to 20Pa within 5 minutes, and the macroporous structure bacterial cellulose membrane (such as Figure 1a and Figure 2a ). Dissolve type I collagen extracted from pig skin with 0.1 mol / L acetic acid aqueous solution at no higher than 20°C to obtain a collagen solution with a concentration of 5 mg / mL. Immerse the bacterial cellulose membrane with macroporous structure in the collagen solution, evacuate to a vacuum degree of 0.09MP to promote the intr...

Embodiment 2

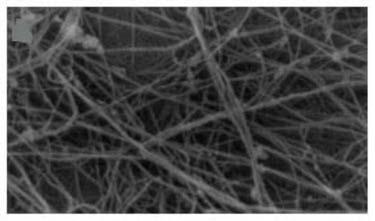

[0053] Place the bacterial cellulose membrane in a beaker and soak it in enough ultrapure water for 24 hours to make it fully absorb water and swell. Then boil with 0.1mol / L NaOH solution for 30min, wash with ultrapure water until neutral, then transfer the bacterial cellulose membrane to 0.05mol / L acetic acid solution for soaking for 24h, wash with ultrapure water until neutral for later use. The purified aqueous bacterial cellulose membrane was placed in a freeze dryer, vacuumed, and the absolute pressure of the system was reduced to 30 Pa within 5 minutes, and the bacterial cellulose membrane with a macroporous structure was obtained after continuing to freeze-dry for 48 hours. Dissolve type I collagen extracted from grass carp skin with 0.1 mol / L acetic acid aqueous solution at no higher than 20°C to obtain a collagen solution with a concentration of 8 mg / mL. Immerse the bacterial cellulose membrane with macroporous structure in the collagen solution, evacuate to a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com