Can roll, long substrate processing device, and management method of long substrate processing device

A drum roll and strip technology, which is applied in the improvement field of strip substrate processing equipment, can solve problems such as gas leakage, difficult flexible wiring substrates, film surface damage or depression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0158] Hereinafter, the Example of this invention is demonstrated concretely.

[0159] [Design of rotary joint]

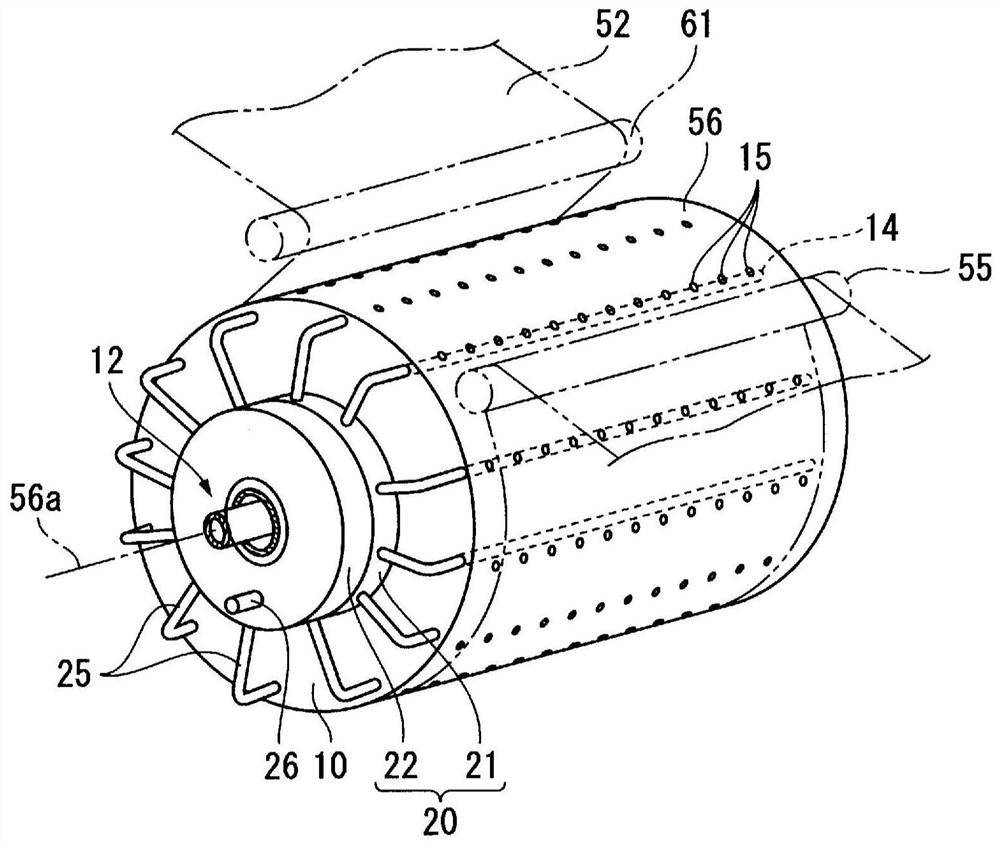

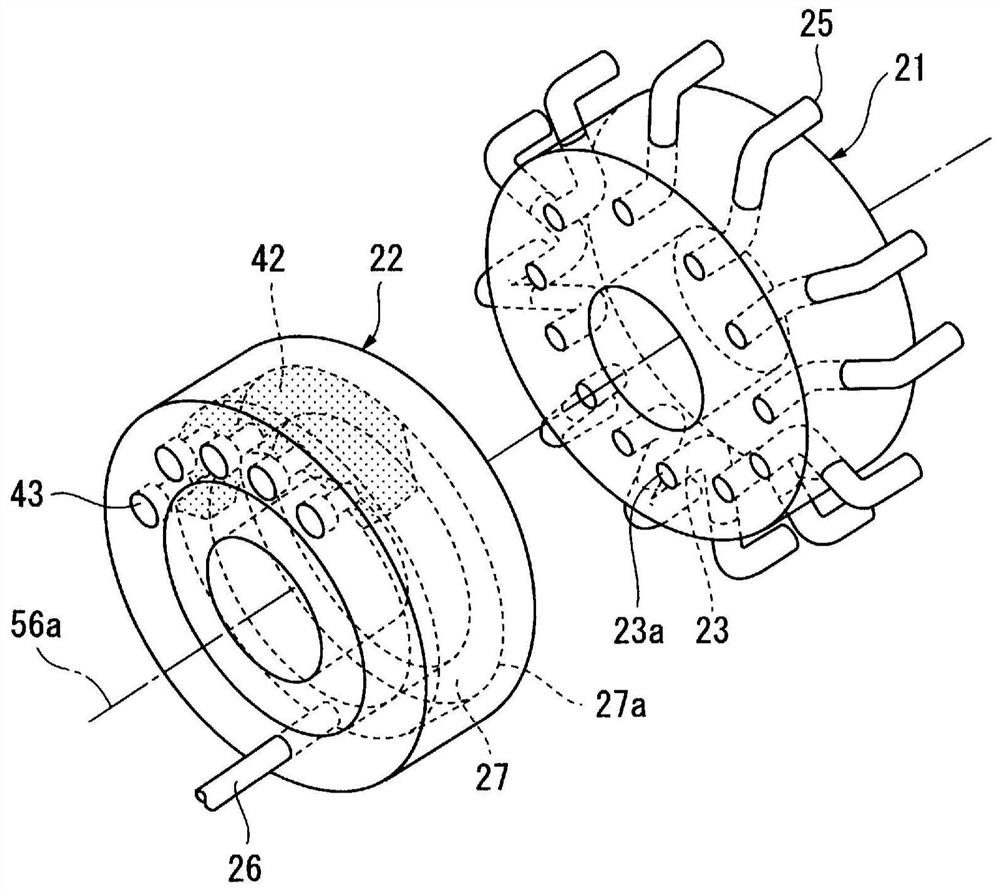

[0160] The diameter of the rotary joint (rotating ring unit and stationary ring unit) was about 400 mm, and the number of connecting pipes 25 in the rotary ring unit connected to (communicating with) the gas introduction passage 14 of the drum roll was 36. Therefore, gas control at an angle of 10° (360° / 36=10°) can be performed.

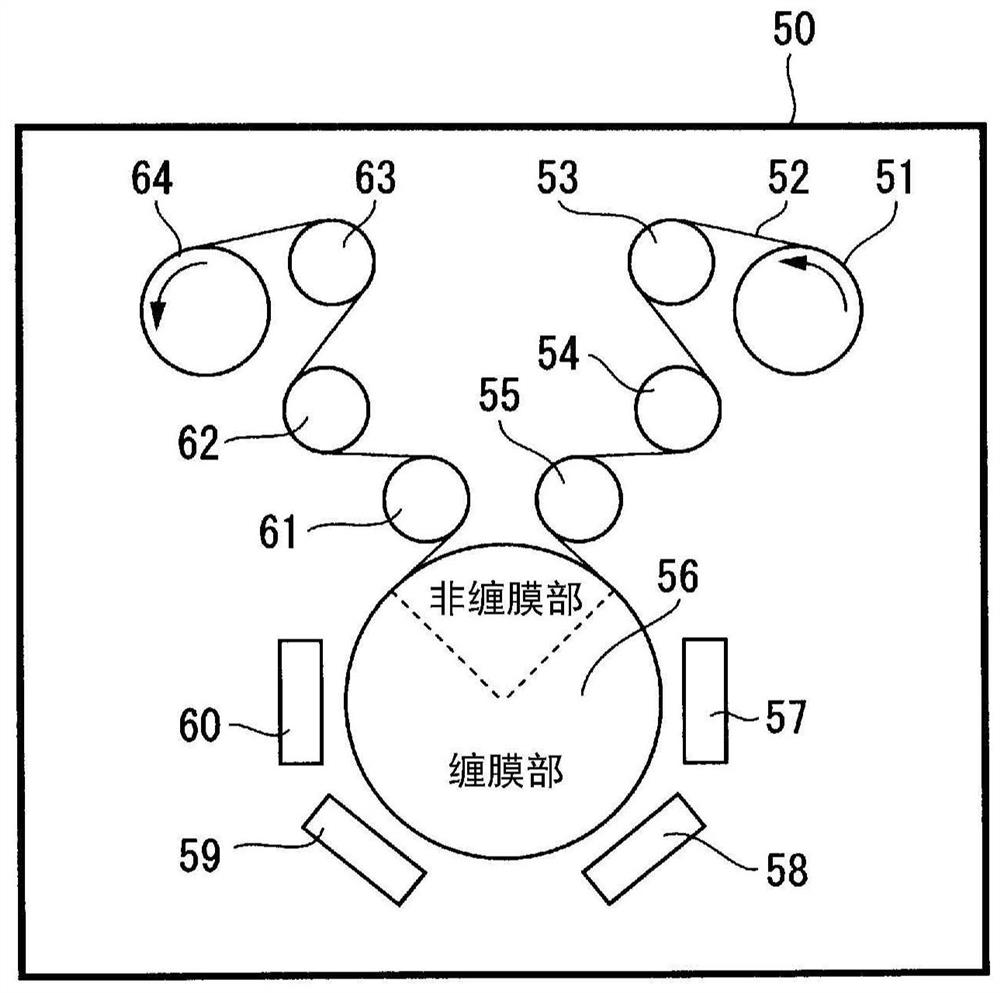

[0161] In addition, the feed roll 55 provided on the feed side of the roll roll was set at an angle of 20° to bring the roll roll into contact with the film, and the feed roll 61 provided on the feed side of the roll roll was set at an angle of 340° The position of the cylinder roll is in contact with the film (ie, the angle of the non-wrapped portion is set to 40°).

[0162] However, the angles before and after the angle of the non-wrapped portion where the gas control is unstable were set to 20°, respectively, and the gas stop angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com