Gas sensor element and gas sensor

A technology for gas sensors and components, applied in instruments, scientific instruments, electrochemical variables of materials, etc., can solve the problems of not easy to improve responsiveness, thickening of layer thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

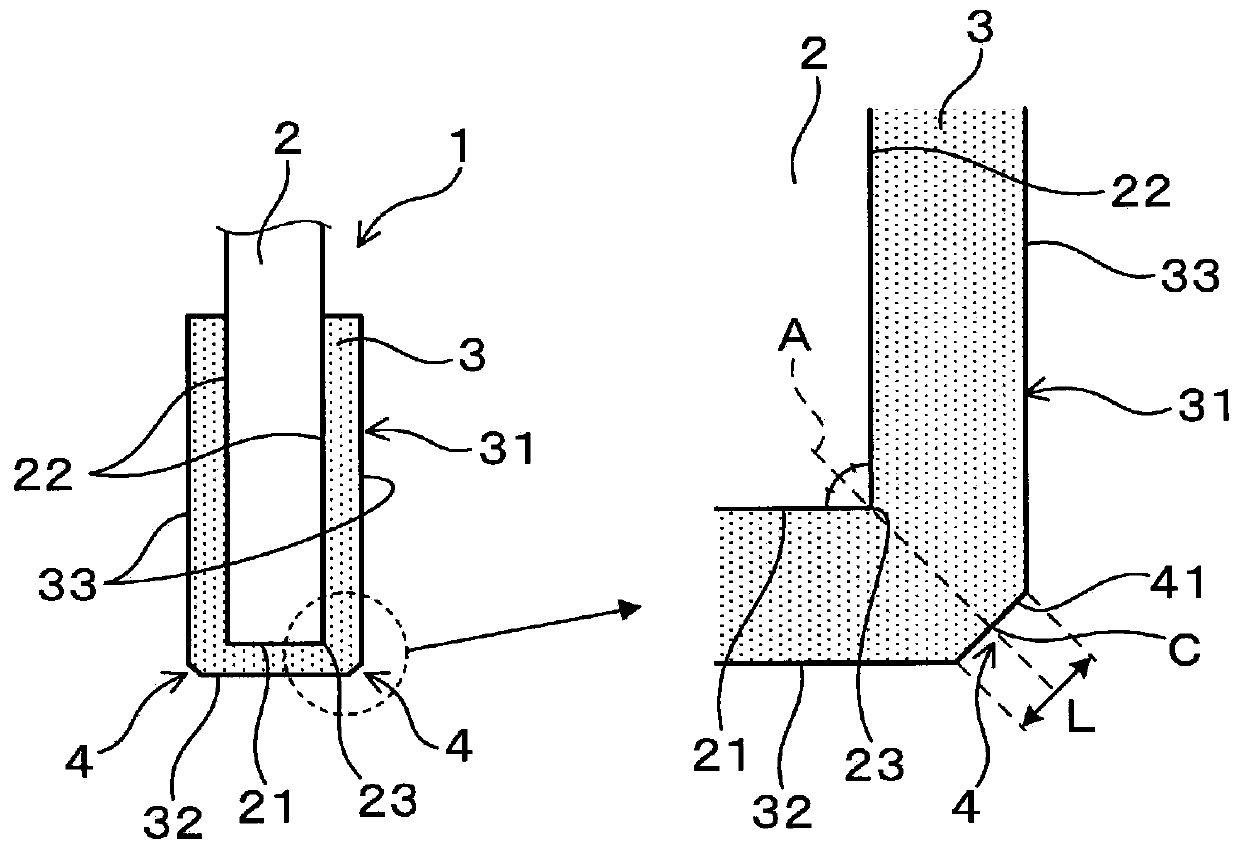

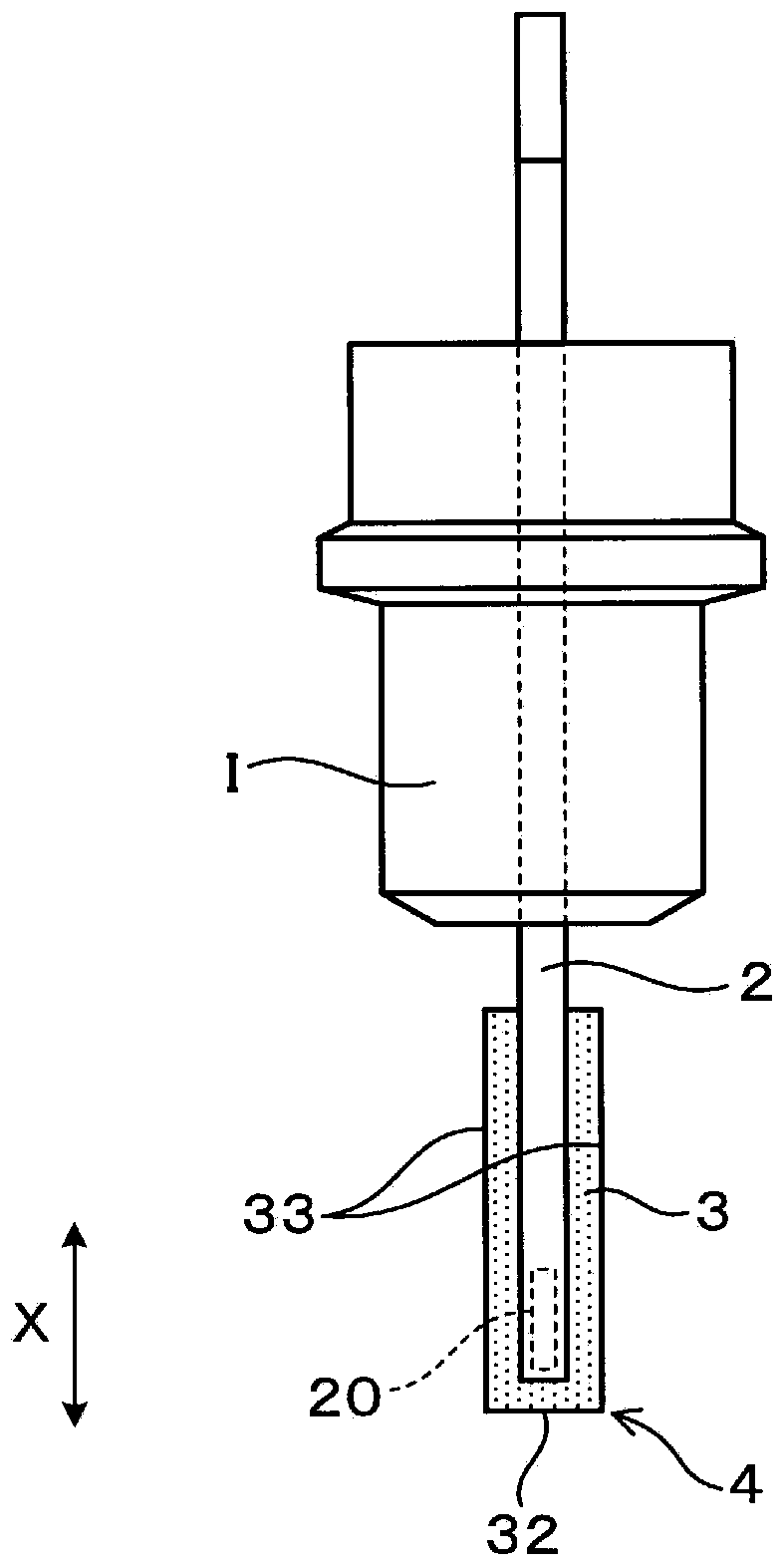

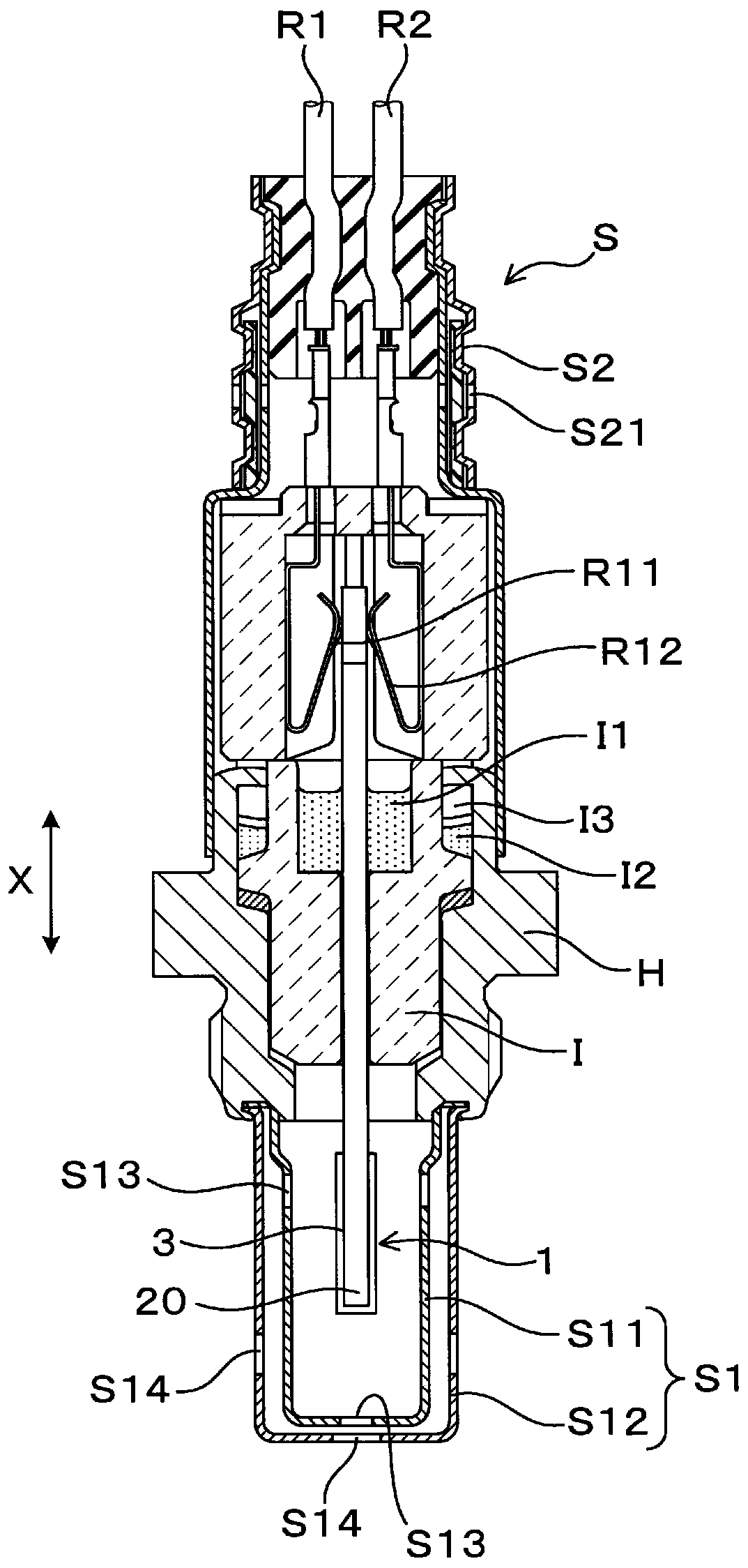

[0044] Below, refer to Figure 1 to Figure 6 Embodiments of the gas sensor element and the gas sensor will be described. figure 1 , figure 2 The gas sensor element 1 shown consists of image 3 The main part of the shown gas sensor S is supported by a cylindrical case H on its outer periphery in a state of being inserted through a cylindrical insulator (insulator) I. The gas sensor S can be applied to, for example, an exhaust purification system of an automobile engine, and the gas sensor element 1 detects a specific gas concentration in exhaust gas as a gas to be measured. Specifically, it can be used for an oxygen sensor that detects an oxygen concentration, an air-fuel ratio sensor that detects an air-fuel ratio (that is, A / F) based on an oxygen concentration, and the like.

[0045] exist figure 1 , figure 2 Among them, the gas sensor element 1 includes a long plate-shaped element body 2 and a porous protective layer 3 that protects the surface of the element body 2...

Embodiment approach 2

[0111] refer to Figure 16 ~ Figure 18 Embodiment 2 of a gas sensor element and a gas sensor will be described. In the gas sensor element 1 of Embodiment 1 described above, the protective layer 3 has a rectangular parallelepiped outer shape substantially similar to the rectangular parallelepiped element main body 2 , but the opposing two surfaces may not necessarily be arranged in parallel. For example, the end surface 32 or the side surface 33 of the protective layer 3 may be inclined relative to the front end surface 21 or the side surface 22 of the element body 2, and the angle formed by the end surface 32 and the side surface 33 may not be a right angle.

[0112] The basic structures of the gas sensor element 1 and the gas sensor S of this embodiment are the same as those of the first embodiment described above, and description thereof will be omitted.

[0113] In addition, among the reference numerals used after the second embodiment, the same reference numerals as those...

Embodiment approach 3

[0131] refer to Figure 21 Embodiment 3 of the gas sensor element and the gas sensor will be described. In the gas sensor element 1 described in each of the above-mentioned embodiments, water repellency can be further improved by imparting hydrophobicity to the protective layer 3 . In order to impart hydrophobicity to the protective layer 3, for example, as described in the above-mentioned Patent Document 1, the protective layer 3 may have a structure having a hydrophobic film on the surface in addition to the structure in which the vapor film (Ledenfrost) phenomenon can occur. .

[0132] The basic structures of the gas sensor element 1 and the gas sensor S of this embodiment are the same as those of the first embodiment described above, and description thereof will be omitted.

[0133] in particular, Figure 21 The structure of the protective layer 3 shown is the same as the above Figure 16 The same is true for the second embodiment shown. The end surface 32 and the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com