Duck egg cleaning, screening and air-drying process

A technology of duck eggs and craftsmanship, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., and can solve the problems of low manual operation efficiency, a large number of manpower, and labor shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

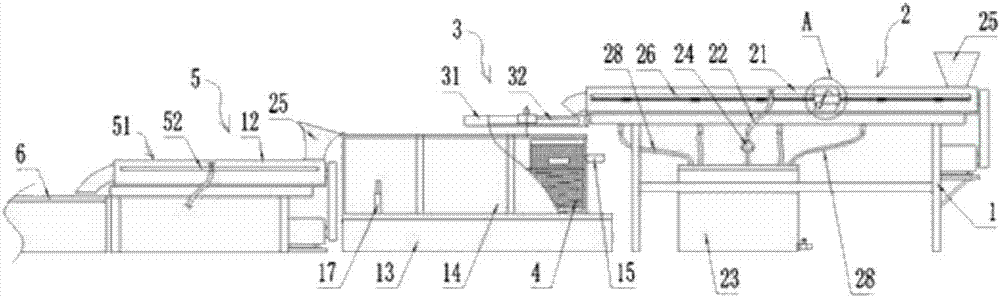

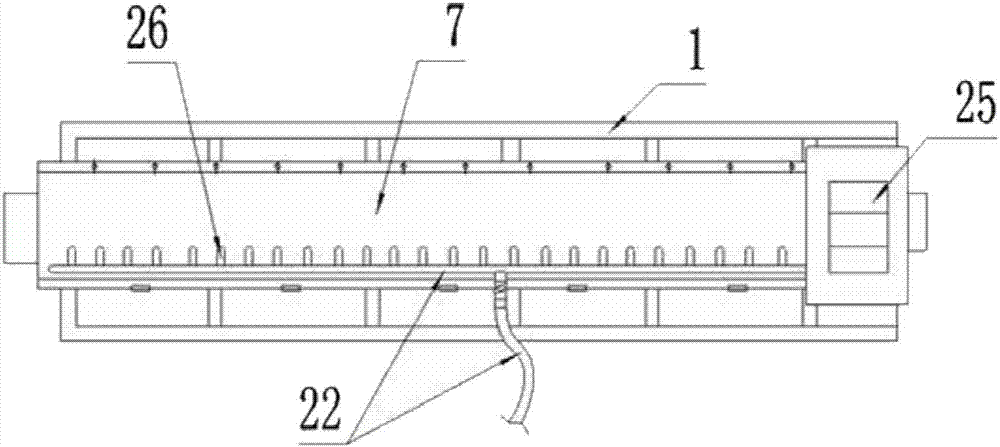

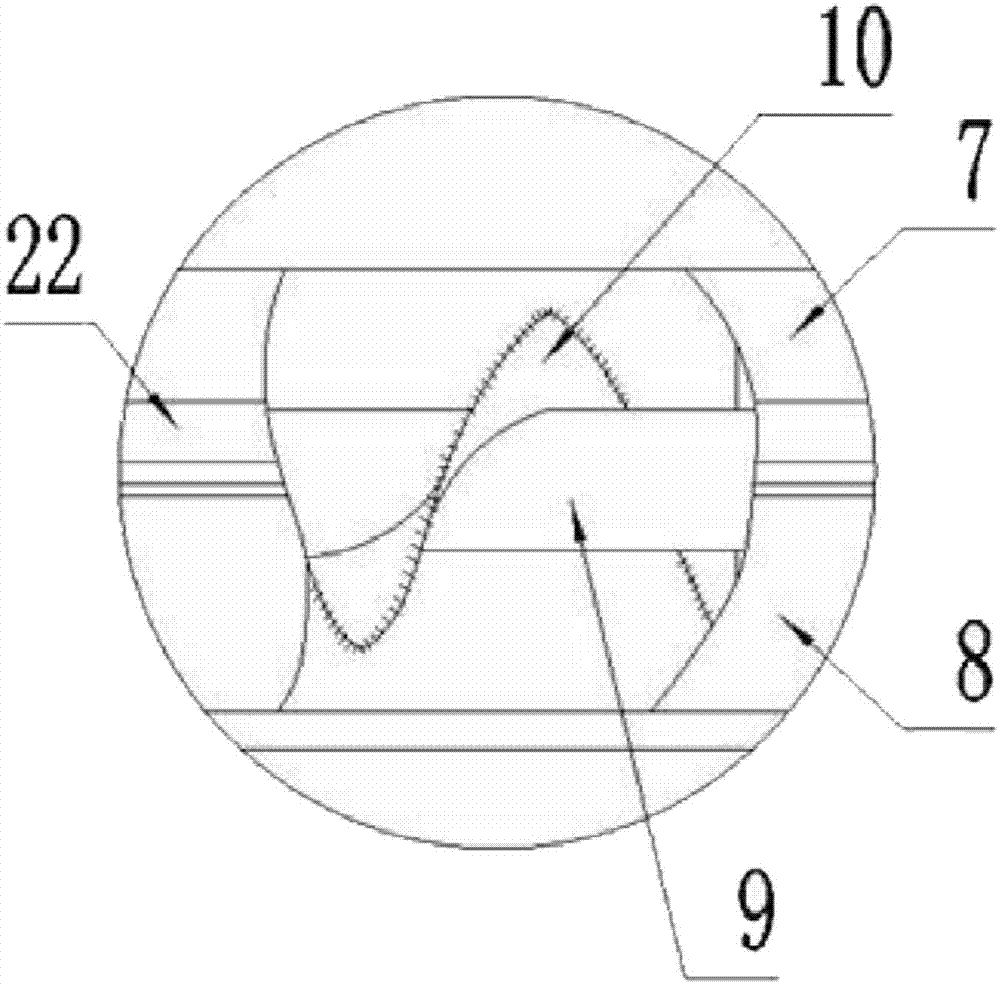

[0026] Such as Figure 1-7 A kind of duck egg cleaning and screening air-drying equipment shown comprises a control box, a frame 1, a cleaning device 2, a screening device 3, a collection basket 4 and an air-drying device 5, and the cleaning device 2 is arranged on the frame 1, and the The cleaning device 2 includes a first screw conveying mechanism 21, a high-pressure water inlet pipe 22, a water storage tank 23 and a pressurizing pump 24. One end of the first screw conveying mechanism 21 is provided with a feed port 25, and on the shell of the first screw conveying mechanism 21 Parallel to its axis, water spray pipes 26 are evenly distributed, and the water spray pipes 26 are connected to the high-pressure water inlet pipe 22. The bottom of the first screw conveying mechanism 21 is provided with a drain pipe 28, and the drain pipe 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap