Symmetrical balance type steel ball finished product washing machine

A symmetrical balance and washing machine technology, applied in cleaning methods and utensils, cleaning methods using liquids, drying solid materials without heating, etc., can solve problems such as increased manufacturing costs, large floor space, and inability to clean with steel balls. Achieve the effect of reducing manufacturing cost, saving human resources, and high cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

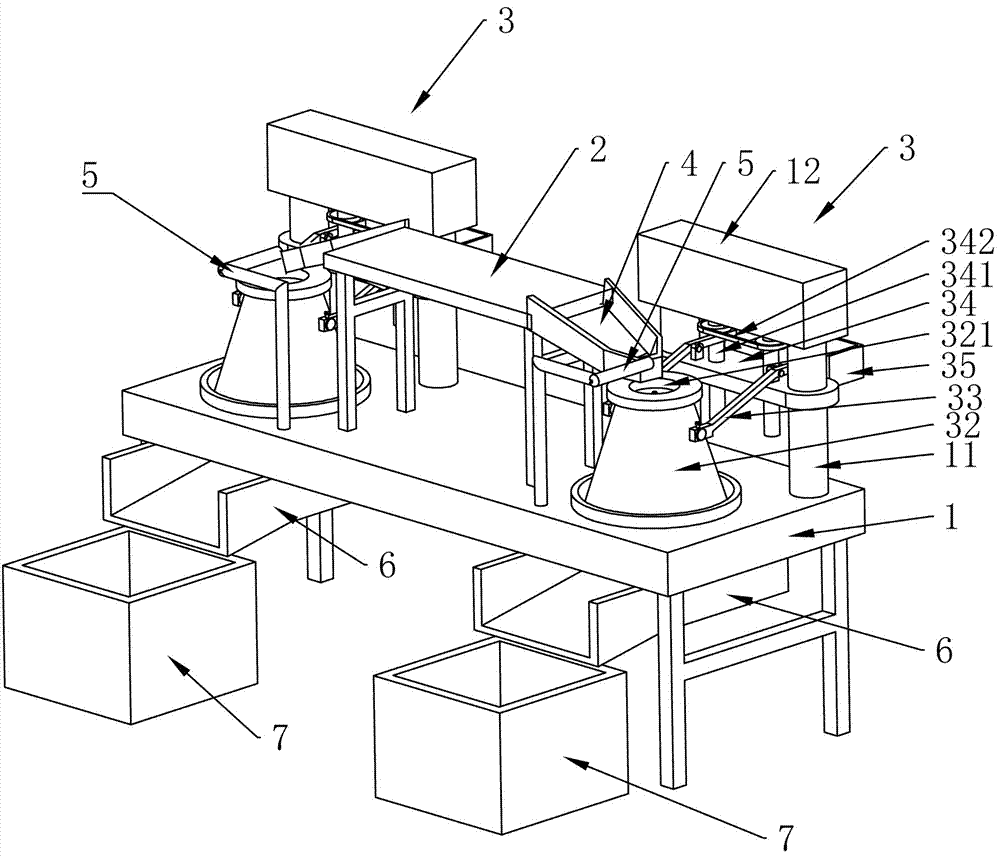

[0029] like Figure 1 to Figure 4 A symmetrical balanced steel ball finished cleaning machine shown includes a frame 1 and a loading frame 2 arranged on the frame 1. The loading frame 2 is used to place the material holding frame, and the frame 1 is also provided with two Two cleaning mechanisms 3 with the same structure are arranged symmetrically with respect to the loading rack 2 .

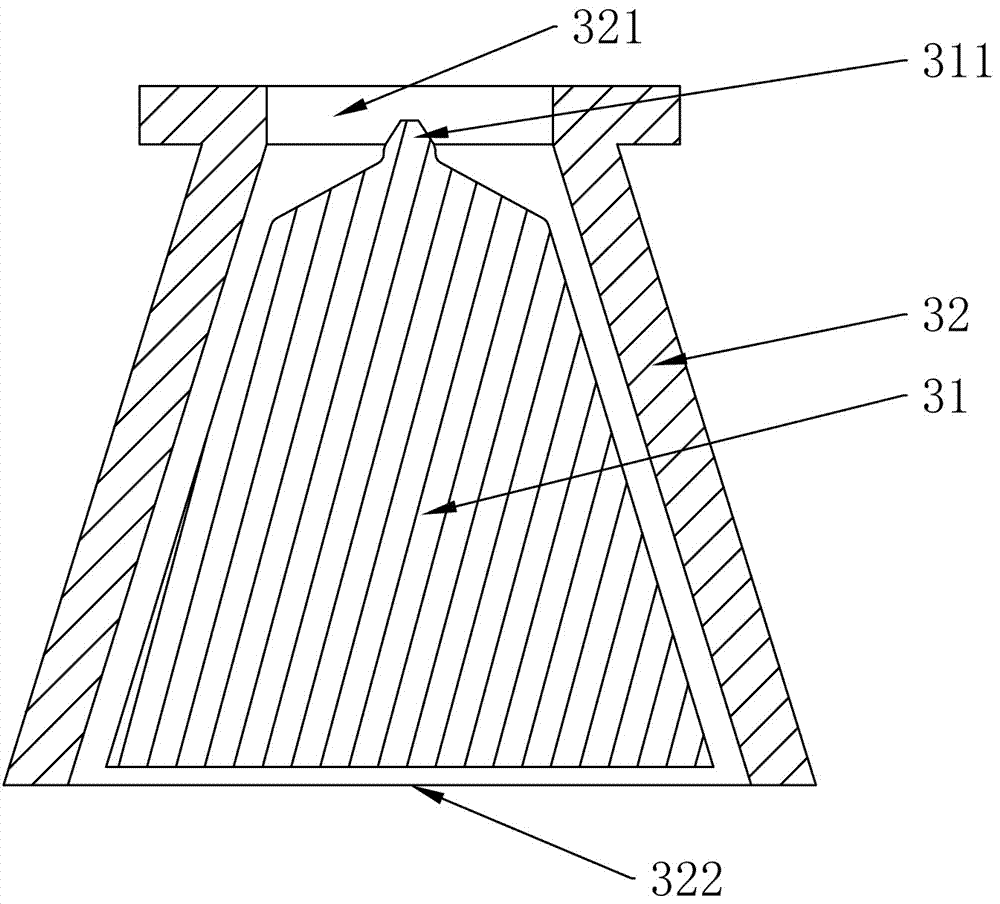

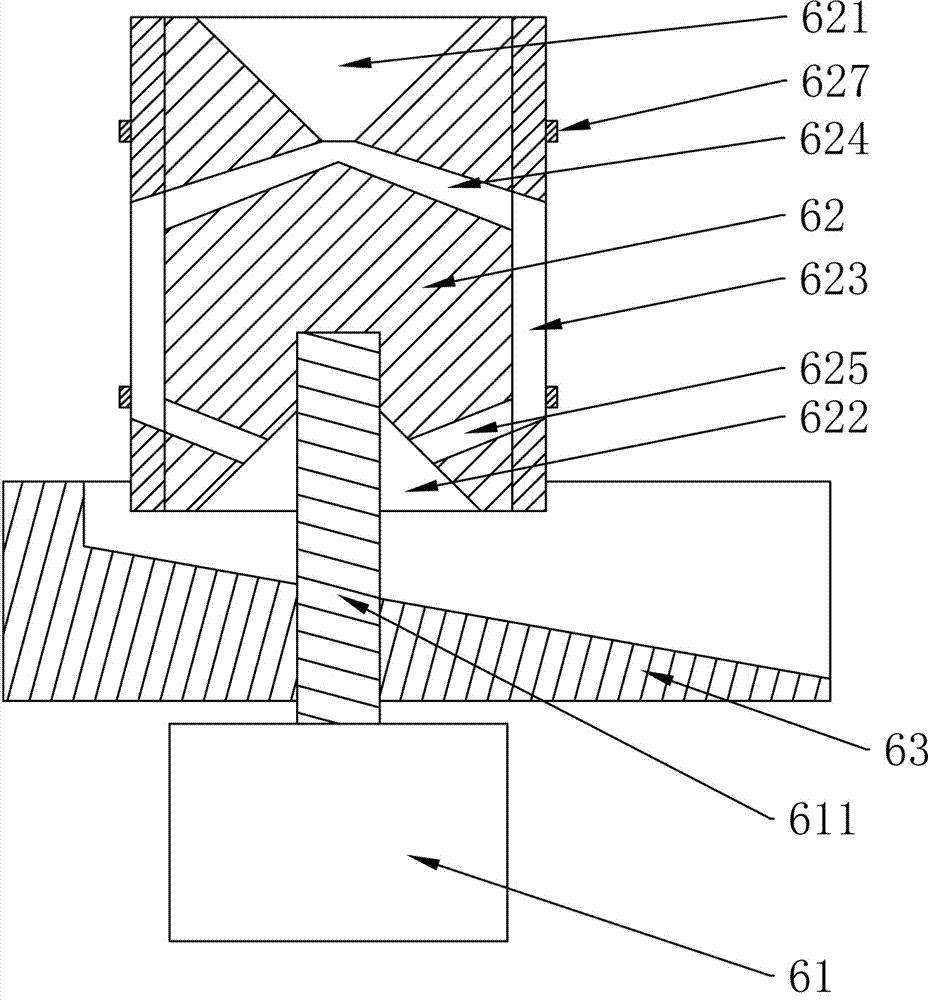

[0030] The cleaning mechanism 3 includes a rotating inner cylinder 31 and a fixed outer cylinder 32 sleeved on the outside of the rotating inner cylinder 31. The rotating inner cylinder 31 is driven by a first motor fixed on the frame 1 to rotate relative to the fixed outer cylinder 32. The rotating inner cylinder 31 The outer wall of the cylinder 31 and the inner wall of the fixed outer cylinder 32 are arranged on a tapered surface with increasing diameter from top to bottom, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com