Mould for concrete experiment and method for concrete vibrating and volume weight measuring by utilizing mould

A technology for concrete and testing, applied in molds, manufacturing tools, auxiliary molding equipment, etc., can solve problems such as differences in concrete quality, and the quality of concrete is easily affected by human factors, so as to reduce physical burden, ensure accuracy and feasibility, Guaranteed matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

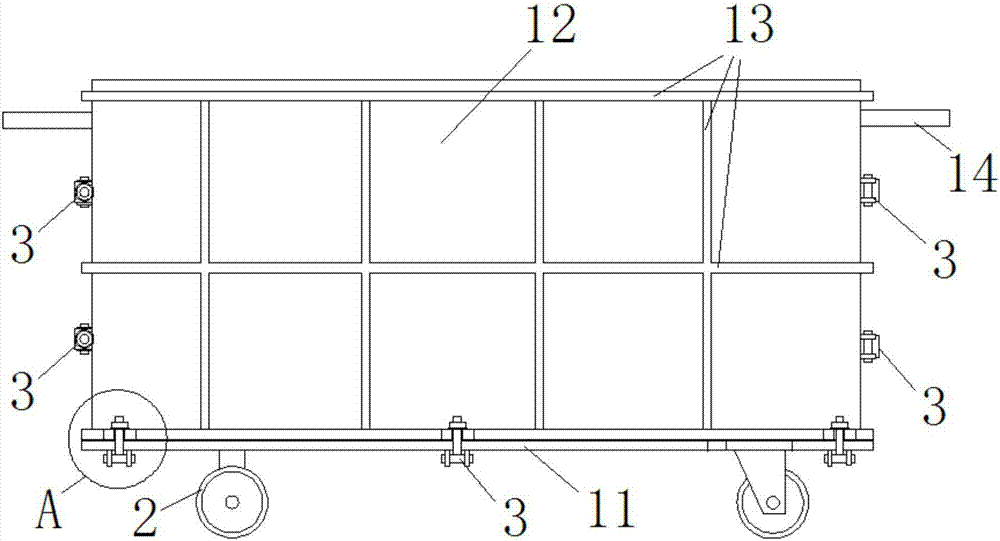

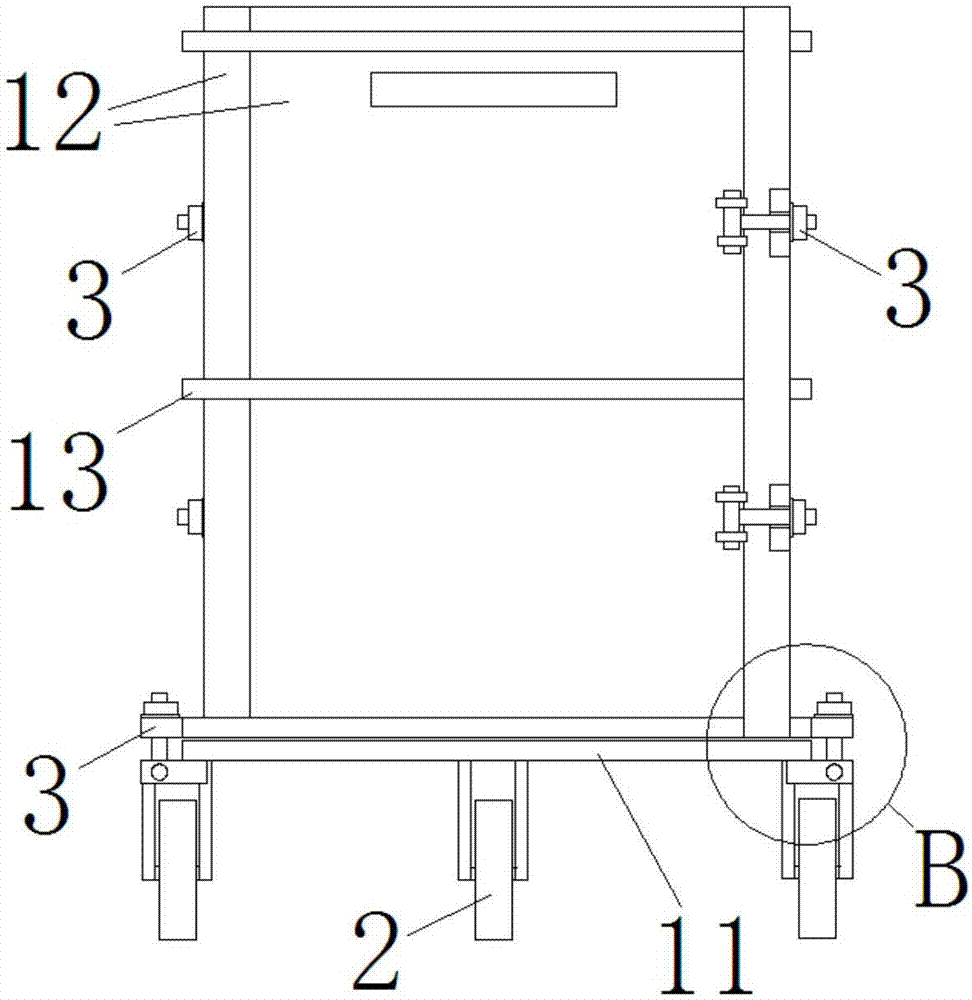

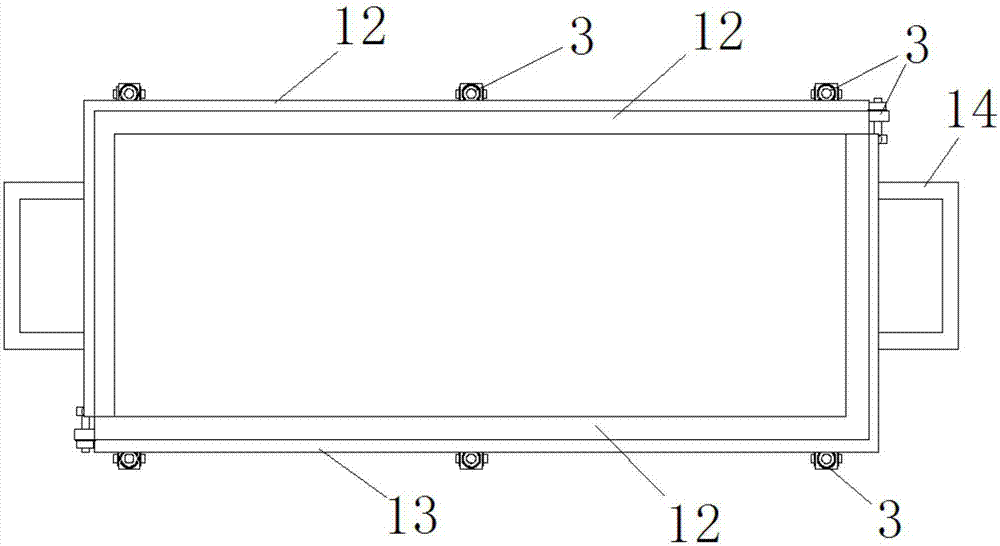

[0024] refer to Figure 1 to Figure 5 , the present embodiment provides a method for using a concrete test mold, the specific method is as follows:

[0025] Step 1: Combine the detachable combined square tank structure to form a mold;

[0026] Step 2: Move the mold to the discharge side of the concrete test performance testing platform, and transfer the concrete from the testing platform to the mold;

[0027] Step 3: Move the mold to the vibrating device of the vibrating rod, and use the vibrating rod to vibrate the concrete in the mold;

[0028] Step 4: Move the vibrated concrete to the weighing scale for weighing, and measure the bulk density of the concrete;

[0029] Step 5: Transfer the mold to the placement area. After the concrete is completely solidified and formed, disassemble the mold and take out the concrete.

[0030] Above-mentioned mold comprises square tank 1, and its internal dimension is length 100cm, width 25cm, height 40cm, and square tank 1 is the detacha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com