Full-automatic semiconductor wafer laser processing device and processing method thereof

A laser processing and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, laser welding equipment, metal processing equipment, etc., can solve the problem of inability to realize seamless connection of laser processing equipment, high fragmentation rate and defective rate, and affecting product quality, etc. problems, to achieve the effect of saving manual transfer steps, improving quality and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

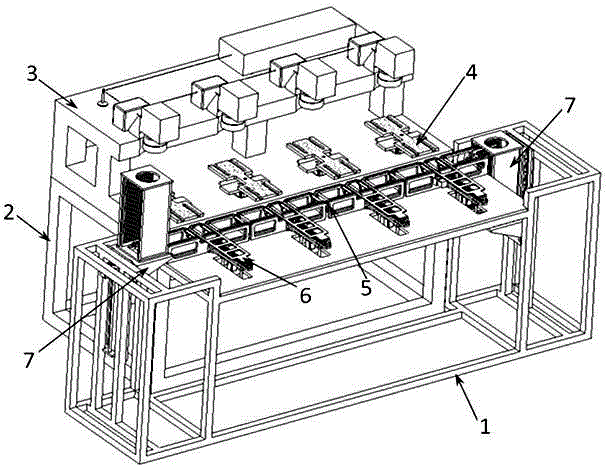

[0035] See figure 1 , a fully automatic semiconductor wafer laser processing device is composed of a front support 1, a rear support 2, a laser processing system 3, four rotating platforms 4, an automatic transmission system 5, and four automatic pick-up / placement devices opposite to the rotating platform 4 wafer system 6 and two wafer cassette lifting systems 7; laser processing system 3 and four rotating platforms 4 are all set on the rear support 2; The wafer magazine lifting system 7 is arranged on the front support 1, and two wafer magazine lifting systems 7 are respectively arranged at both ends of the automatic transmission system 5;

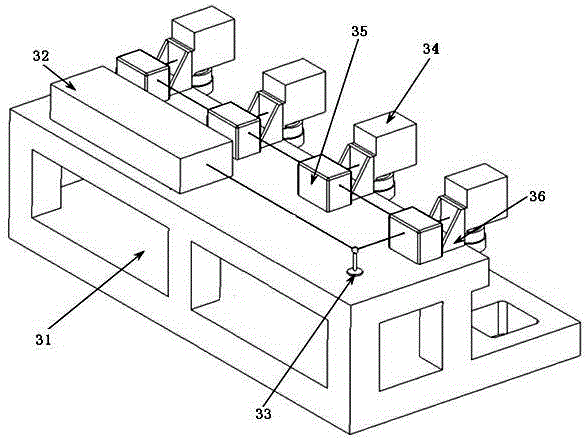

[0036] See figure 2 , the laser processing system 3 includes a two-layer stepped support platform 31, a laser 32, a reflector 33, four scanning galvanometers 34 opposite to the rotary platform 4, and four beam splitters and lasers that cooperate with each scanning galvanometer 34 respectively. Beam power real-time monitoring and adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com