Bushing, knuckle and press-fitting technique for bushing and knuckle

A technology for steering knuckles and bushings, which is applied to steering mechanisms, steering rods, transportation and packaging, etc. It can solve problems such as difficult control of coaxiality, pressure loss of bushings, and difficulty in pressing and fitting, so as to simplify the operation process and improve Alignment and stability, simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

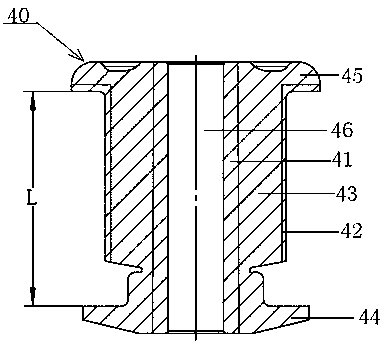

[0050] The bushing 40 includes a bushing main body with an intermediate shaft hole 46, and the bushing main body is composed of a bushing inner tube 41, a bushing outer tube 42 and an intermediate tube between the bushing inner tube 41 and the bushing outer tube 42. Composed of rubber body 43, one axial side of the bushing main body is provided with rubber dust-proof side ears 44 radially extending along the outer wall of the bushing inner tube 41; the other axial side of the bushing main body is provided with a bushing The sleeve flange 45; the bushing inner tube 41 and the bushing outer tube 42 are hard tubes made of metal materials; the diameter of the rubber dust-proof side ear 44 is larger than the diameter of the bushing outer tube 42 The wall thickness of the bushing outer tube 42 is smaller than the wall thickness of the bushing inner tube 41, and the inner end face of the bushing flange 45 of the bushing 40 and the inner end face of the rubber dust-proof side lug 44 ar...

Embodiment 2

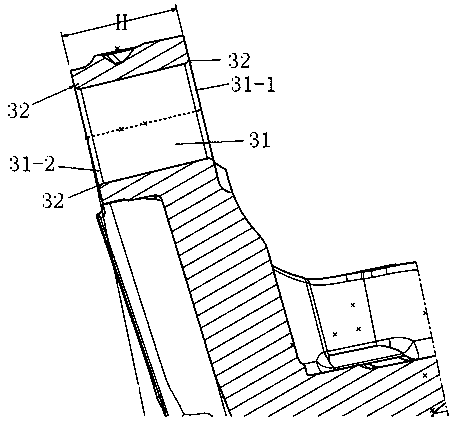

[0052] The steering knuckle 30 for installing the bushing 40 described in Embodiment 1 includes a steering knuckle body, and the steering knuckle body is provided with a steering knuckle bushing hole 31 for installing the bushing 40, according to the pressing order of the bushings , the press-in orifice 31-1 and the press-out orifice 31-2 of the steering knuckle bushing hole 31 are both designed as a rounded structure. The hole height of the steering knuckle bushing hole 31 is 48±0.2mm, and the height distance from the inner end surface of the bushing flange 45 of the bushing 40 to the inner end surface of the rubber dust-proof side lug 44 is 47.5mm; the press-in hole The fillet radius R of the mouth 31-1 and the pressure outlet orifice is 2.2-2.5 mm.

Embodiment 3

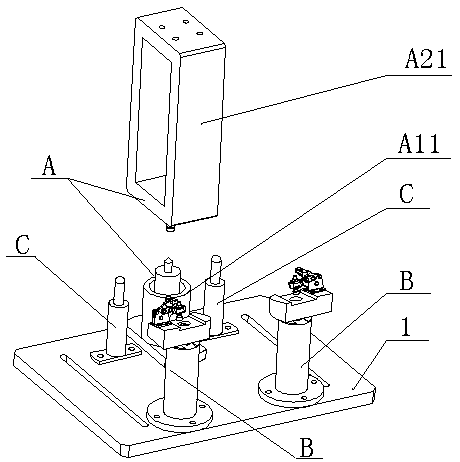

[0054] The bush press-fitting process for the bush 40 described in Embodiment 1 and the steering knuckle 30 described in Embodiment 2 includes the following specific steps:

[0055] Step 1: Install the Bushing

[0056] Install the bushing 40 on the pressure head A21-1 of the press-fitting equipment, and evenly apply castor oil on the surface of the rubber dust-proof ear 44;

[0057] Step 2: Fix the steering knuckle

[0058] Fix the steering knuckle 30 on the press-fitting tool, and position the steering knuckle bushing hole 31 of the steering knuckle 30 on the main control mechanism A of the press-fitting tool;

[0059] Step 3: Pressing

[0060] Start the press-fitting equipment, the press head A2 drives the bush 40 to drop slowly, and when it reaches the knuckle bush hole 31, the rubber dust-proof side ear 44 is slowly folded at the press-in hole 31-1 of the knuckle bush hole 31, Then press the bushing 40 into the steering knuckle bushing hole 31, and continue to press dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com