High-quality ornithine extraction method

An extraction method, ornithine technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of long time, enzyme inactivation, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

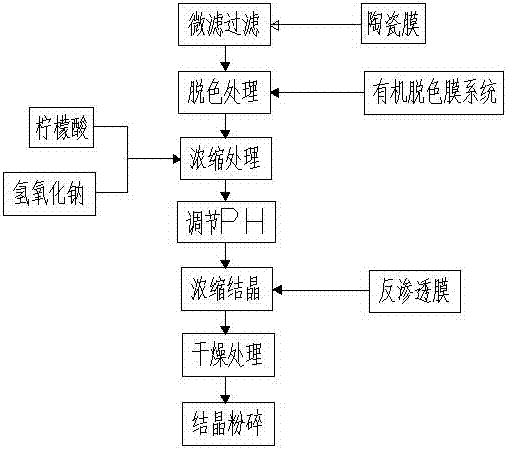

[0025] now attached figure 1 The present invention will be further described in detail with specific embodiments.

[0026] Concrete embodiment manufacturing steps are as follows:

[0027] A high-quality ornithine extraction method, the extraction process steps comprising:

[0028] Step 1, microfiltration filtration: Put the fermented liquid of ornithine into the primary filtration equipment to obtain the microfiltration dialysate; filter through the ceramic membrane, and remove the bacteria, colony, mycelium, and insoluble protein And remove impurities such as soluble macromolecular proteins;

[0029] Step 2, decolorization treatment: put the obtained microfiltration dialysate into the organic decolorization membrane system for decolorization treatment to obtain decolorization solution; through the organic decolorization membrane system for decolorization treatment, soluble small molecular protein, salt, pigment and other substances, wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap