Method for Avoiding Cracking of Polystyrene Hollow Microspheres in Drying Process

A polystyrene microsphere and polystyrene technology, applied in the direction of coating, can solve the problems of reduced mechanical properties, narrowed application field, increased surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

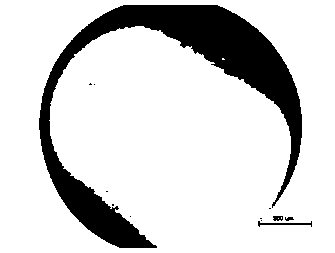

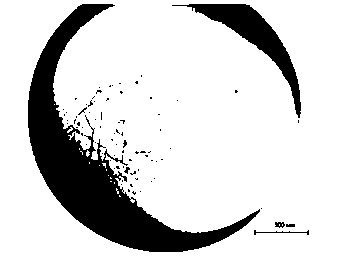

Image

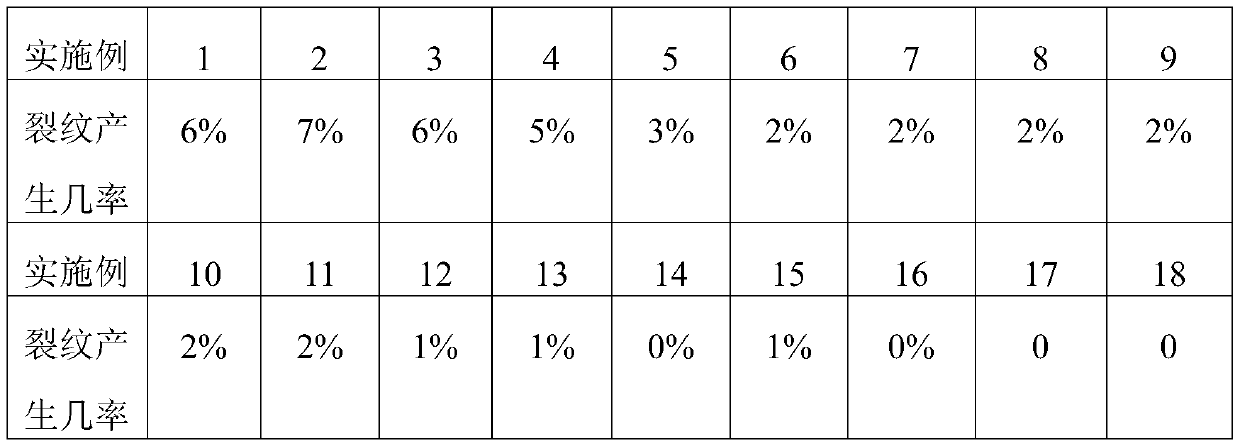

Examples

Embodiment 1

[0032] A method for avoiding cracking of polystyrene hollow microspheres during drying, comprising the following steps:

[0033] Step 1. Add polyvinyl alcohol aqueous solution with a mass fraction of 1% into the rotary evaporator of the rotary evaporator, and then place the water-containing polystyrene microspheres in the rotary evaporator; set the temperature of the rotary evaporator to 75 ° C, rotate The speed is 25 rpm for 3 hours, and the solution containing polystyrene hollow microspheres is poured into a grading sieve to obtain high-temperature cured microspheres; the weight ratio of the polystyrene microspheres and polyvinyl alcohol aqueous solution is 1:10 ;

[0034] Step 2. Wash the high-temperature solidified microspheres with distilled water several times, then place them in ethanol for full exchange for 1 hour, discard the microspheres that sink to the bottom of the ethanol, and collect the microspheres that float on the surface of ethanol;

[0035] Step 3, drying...

Embodiment 2

[0038] A method for avoiding cracking of polystyrene hollow microspheres during drying, comprising the following steps:

[0039] Step 1. Add polyvinyl alcohol aqueous solution with a mass fraction of 5% into the rotary evaporator of the rotary evaporator, then place the water-containing polystyrene microspheres in the rotary evaporator; set the temperature of the rotary evaporator to 100 ° C, rotate The speed is 45rpm for 5h, and the solution containing polystyrene hollow microspheres is poured into a grading sieve to obtain high-temperature cured microspheres; the weight ratio of the polystyrene microspheres and polyvinyl alcohol aqueous solution is 1:50 ;

[0040] Step 2. Wash the high-temperature solidified microspheres with distilled water several times, then place them in ethanol for full exchange for 3 hours, discard the microspheres that sink to the bottom of the ethanol, and collect the microspheres that float on the surface of ethanol;

[0041] Step 3, drying the colle...

Embodiment 3

[0044] A method for avoiding cracking of polystyrene hollow microspheres during drying, comprising the following steps:

[0045] Step 1, take a mass fraction of 3% polyvinyl alcohol aqueous solution and add it to the rotary evaporator of the rotary evaporator, then place the water-containing polystyrene microspheres in the rotary evaporator; set the temperature of the rotary evaporator to 85 ° C, rotate The speed is 35rpm for 4h, and the solution containing polystyrene hollow microspheres is poured into a grading sieve to obtain high-temperature cured microspheres; the weight ratio of the polystyrene microspheres containing water to the polyvinyl alcohol aqueous solution is 1:30 ;

[0046] Step 2. Wash the high-temperature solidified microspheres with distilled water several times, then place them in ethanol for full exchange for 2 hours, discard the microspheres that sink to the bottom of the ethanol, and collect the microspheres that float on the surface of ethanol;

[0047...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com