A Sound Source Separation Method for Railside Acoustic Fault Detection of Train Bearings

A technology of fault detection and separation method, which is used in mechanical bearing testing, measuring devices, testing of mechanical components, etc., and can solve problems such as poor denoising effect, inability to eliminate in-band noise, and inaccurate diagnosis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

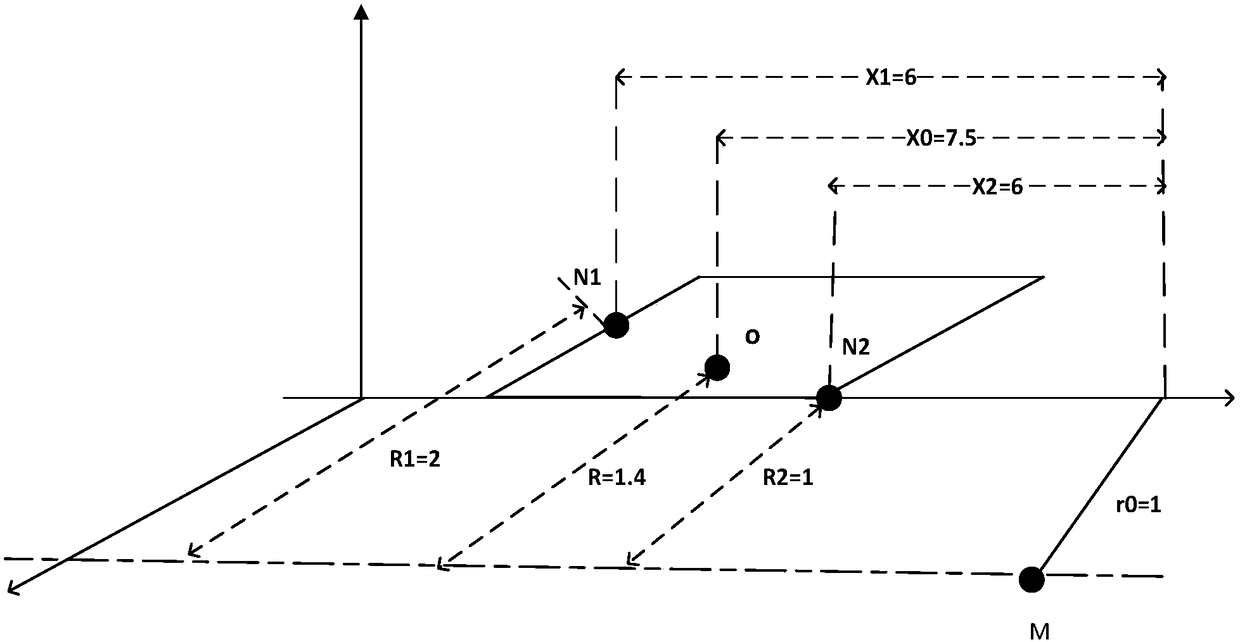

[0080] The trackside simulation sound signal of a single point fault on the outer ring of the high-speed train wheelset bearing is analyzed and processed. In order to verify the effectiveness of the method, two noise signals with different geometric positions are added in the same plane of the trackside signal. Sampling frequency 5KHz,

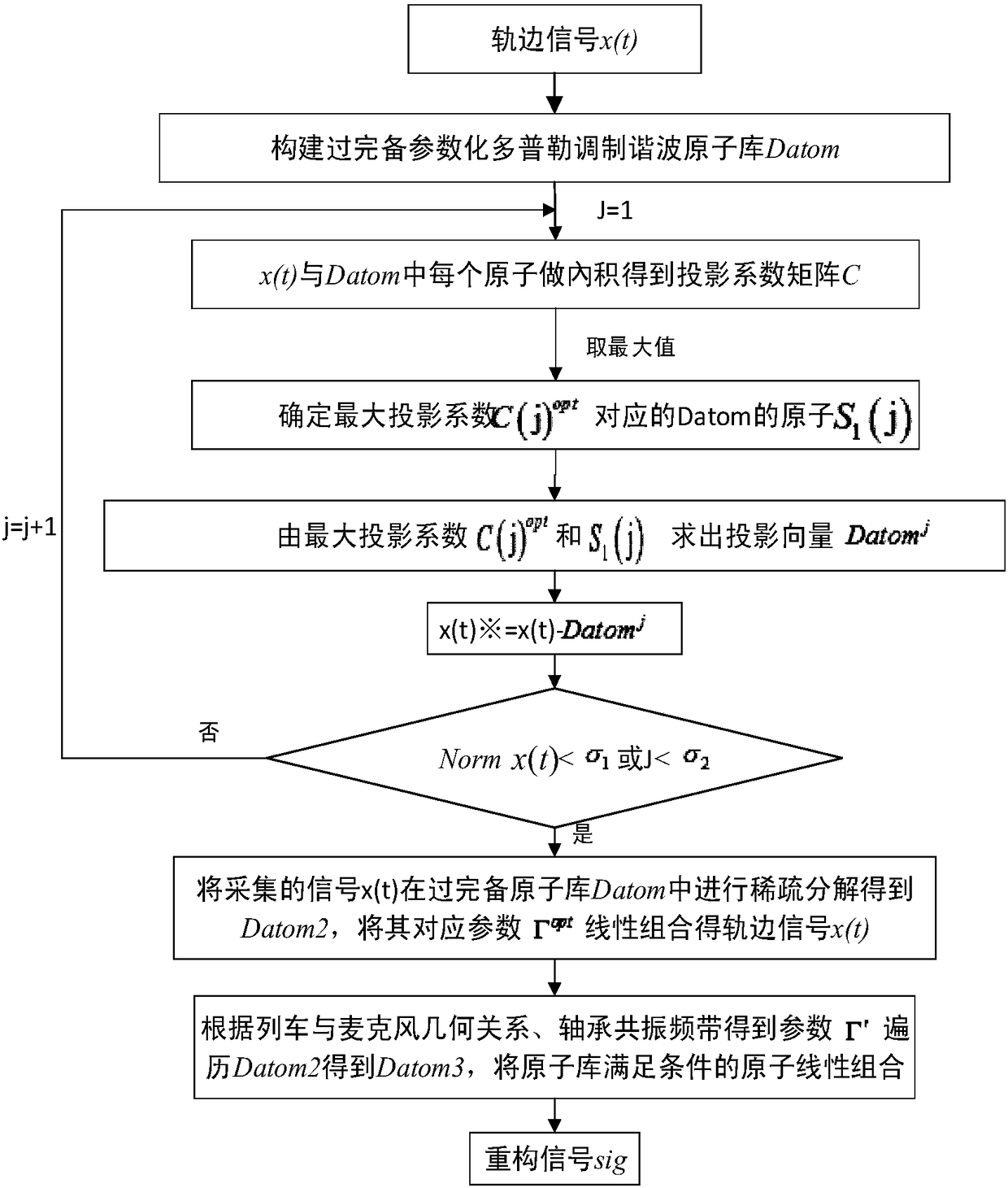

[0081] figure 1 It is a flow chart of the sound source separation method for acoustic detection of train bearing trackside in the invention. Use the microphones installed on both sides of the rails to collect the fault sound signal from the wheel set bearing when the train passes at high speed, and use it as the detection signal x(t). The processing steps for the detection signal are as follows:

[0082] (1-1) Constructing a complete parameterized Doppler modulated harmonic atomic library:

[0083] Datom={S 0 (i),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com