Reduced graphene modified nickel-iron hydroxyl oxide electrode as well as preparation method and application thereof

A graphene electrode and graphene technology, applied to the electrochemical variables of materials, material analysis by electromagnetic means, and measurement devices, can solve problems such as poor conductivity, improve conductivity, promote electrocatalytic oxygen evolution reaction, increase The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

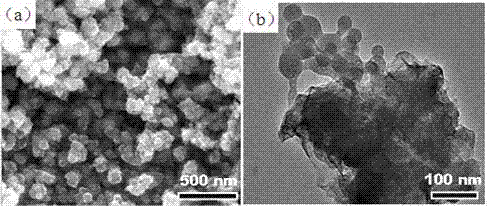

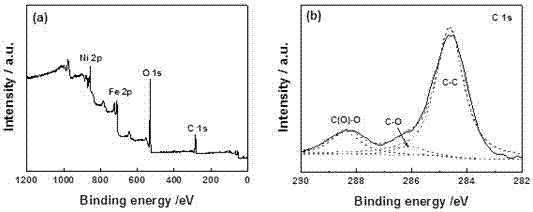

[0032] A method for preparing a reduced graphene-modified nickel-iron oxyhydroxide electrode, comprising the following steps:

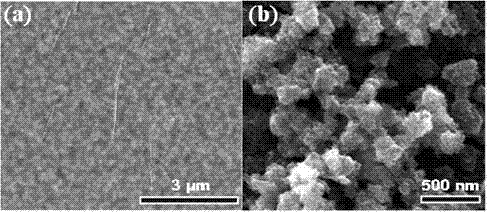

[0033] (1) Place the FTO conductive glass on the rotating disk of the spin coater, pipette 100 μL of graphene oxide ethanol solution dropwise on the FTO conductive glass, and fix the coating area to 1cm 2 , the rotation speed of the rotating disc is 3000 rpm, and it is maintained for 30 seconds, which is used as a spin-coating cycle; repeat the spin-coating cycle 10 times to obtain a graphene oxide (GO / FTO) electrode; wherein, in the ethanol solution of graphene oxide The concentration of graphene oxide is 0.2g / L;

[0034] (2) Place the GO / FTO electrode obtained in step (1) in a tube furnace, raise the temperature to 500°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2 hours, and cool it to room temperature naturally to obtain reduced graphite ene (RGO / FTO) electrode;

[0035] (3) With the RGO / FTO electrode obtained in step (2) as the wo...

Embodiment 2

[0037] A method for preparing a reduced graphene-modified nickel-iron oxyhydroxide electrode, comprising the following steps:

[0038] (1) Place the FTO conductive glass on the rotating disk of the spin coater, pipette 100 μL of graphene oxide ethanol solution dropwise on the FTO conductive glass, and fix the coating area to 1cm 2 , the rotation speed of the rotating disc is 3000 rpm, and it is maintained for 30 seconds, which is used as a spin-coating cycle; repeat the spin-coating cycle 10 times to obtain a graphene oxide (GO / FTO) electrode; wherein, in the ethanol solution of graphene oxide The concentration of graphene oxide is 0.2g / L;

[0039] (2) Place the GO / FTO electrode obtained in step (1) in a tube furnace, raise the temperature to 500°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2 hours, and cool it to room temperature naturally to obtain reduced graphite ene (RGO / FTO) electrode;

[0040] (3) The RGO / FTO electrode obtained in step (2) is used as t...

Embodiment 3

[0043] A method for preparing a reduced graphene-modified nickel-iron oxyhydroxide electrode, comprising the following steps:

[0044] (1) Place the FTO conductive glass on the rotating disk of the spin coater, pipette 100 μL of graphene oxide ethanol solution dropwise on the FTO conductive glass, and fix the coating area to 1cm 2 , the rotation speed of the rotating disc is 3000 rpm, and it is maintained for 30 seconds, which is used as a spin-coating cycle; repeat the spin-coating cycle 10 times to obtain a graphene oxide (GO / FTO) electrode; wherein, in the ethanol solution of graphene oxide The concentration of graphene oxide is 0.2g / L;

[0045] (2) Place the GO / FTO electrode obtained in step (1) in a tube furnace, raise the temperature to 500°C at a rate of 2°C / min in a nitrogen atmosphere, keep it for 2 hours, and cool it to room temperature naturally to obtain reduced graphite ene (RGO / FTO) electrode;

[0046] (3) The RGO / FTO electrode obtained in step (2) is used as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap