Production line workshop scheduling method and production line workshop scheduling device

A workshop scheduling and assembly line technology, applied in control/regulation systems, comprehensive factory control, instruments, etc., can solve the problems of local optimization, low efficiency of later iterations, and low production efficiency of flow workshops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

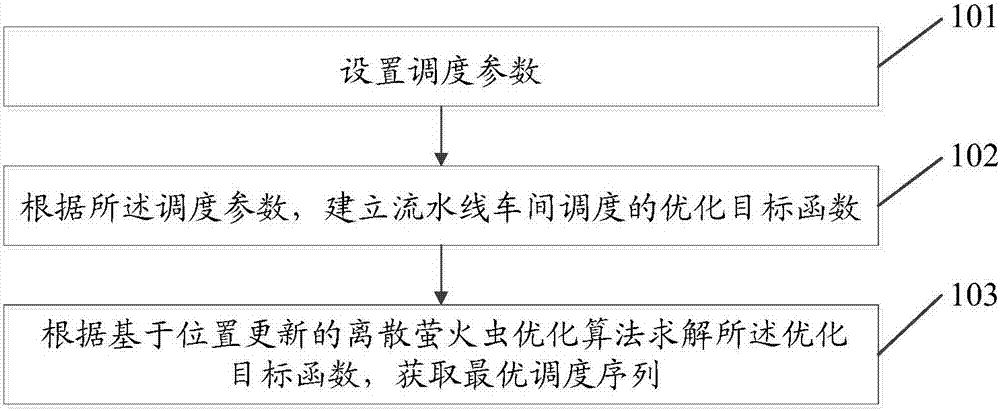

[0046] An assembly line workshop scheduling method provided by an embodiment of the present invention, such as figure 1 As shown, the method includes:

[0047] Step 101: setting scheduling parameters;

[0048] Here, the setting scheduling parameters refer to setting scheduling parameters related to the assembly line workshop scheduling problem, including the number of workpieces, the number of machines, and unit processing time; the unit processing time refers to the processing time of each workpiece on each machine.

[0049] Here, the pipeline shop scheduling problem (Permutation Flow Shop SchedulingProblem, PFSP) can be described as: there are n workpieces to be processed on E machines, each workpiece needs to go through E procedures, and each procedure requires different machines Processing, the processing sequence of n workpieces on E machines is the same, and the processing sequence of n workpieces on each machine is also the same; the solution goal of the assembly line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com