Body in white module design method based on modularization product family platform

A modular design and product family technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of late start of modular technology and low modular design ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

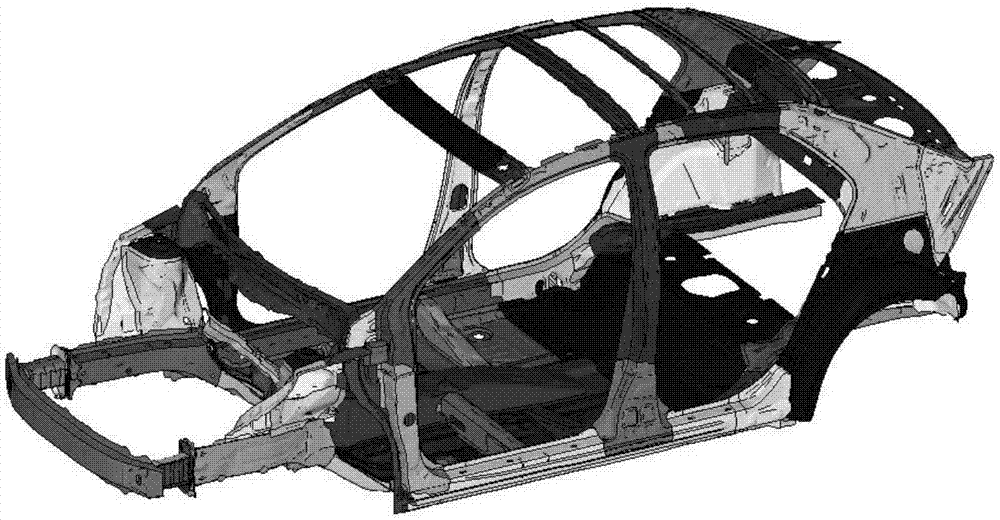

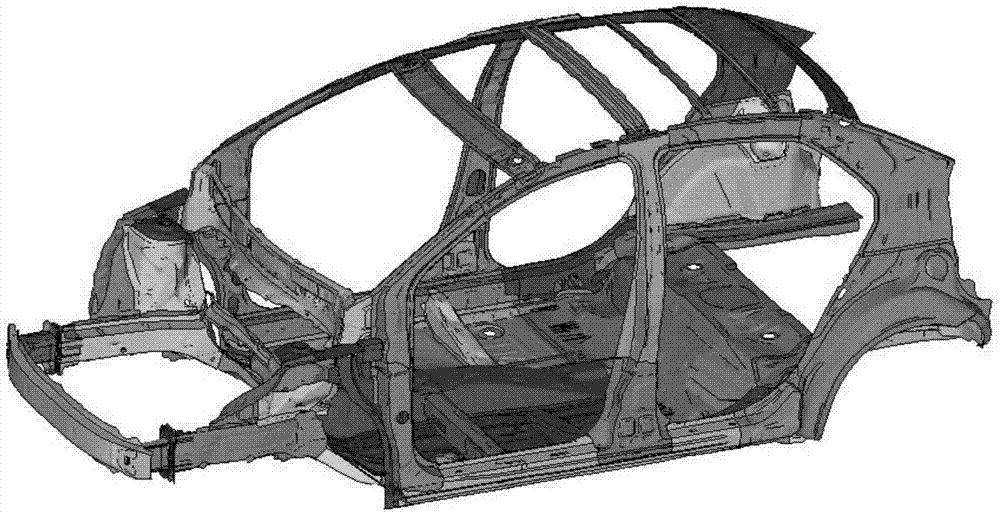

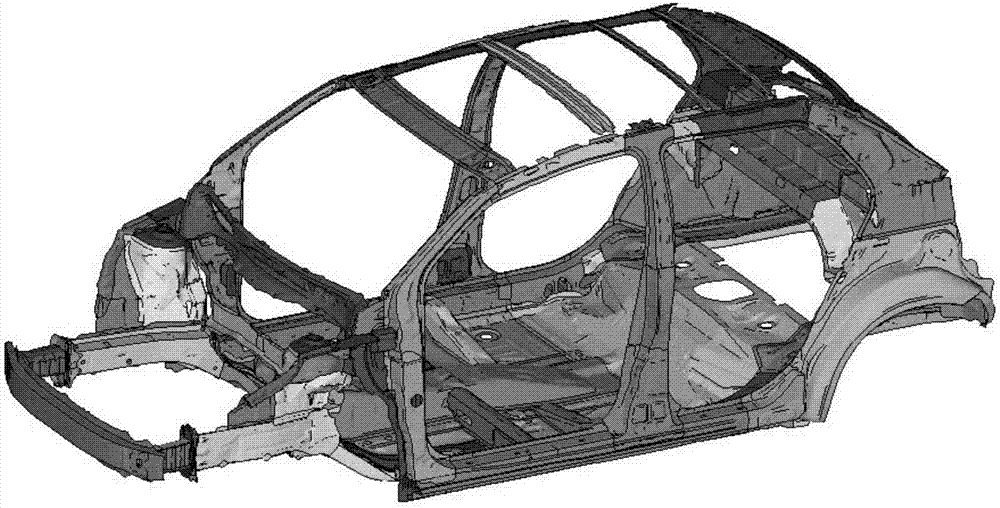

[0052] As shown in Figure 1, the three compartments ( Figure 1a ), Hatchback ( Figure 1b ) and SUV ( Figure 1c ) three models, of which the sedan model and the hatchback model have the same wheelbase, and the SUV model is larger than the other two models, with an axial gap of up to 300mm. The method of the present invention is mainly used to carry out assembly design based on modular manufacturing for "cross-class" vehicle models in the traditional sense with large size differences as shown in the figure. For "same level" vehicle models with smaller size differences, the method of the present invention can be simplified and applied according to actual conditions.

[0053] According to the actual manufacturing and assembly process level, the manufacturing unit pre-segmentation of the body-in-white bottom plate is carried out. According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com