A locking structure for connector fitting insertion

A locking structure and connector technology, which is applied to the parts, connections, electrical components and other directions of the connecting device, can solve the problems of inability to directly insert and pull out, inapplicability, etc., and achieve the effects of convenient operation, compact structure and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

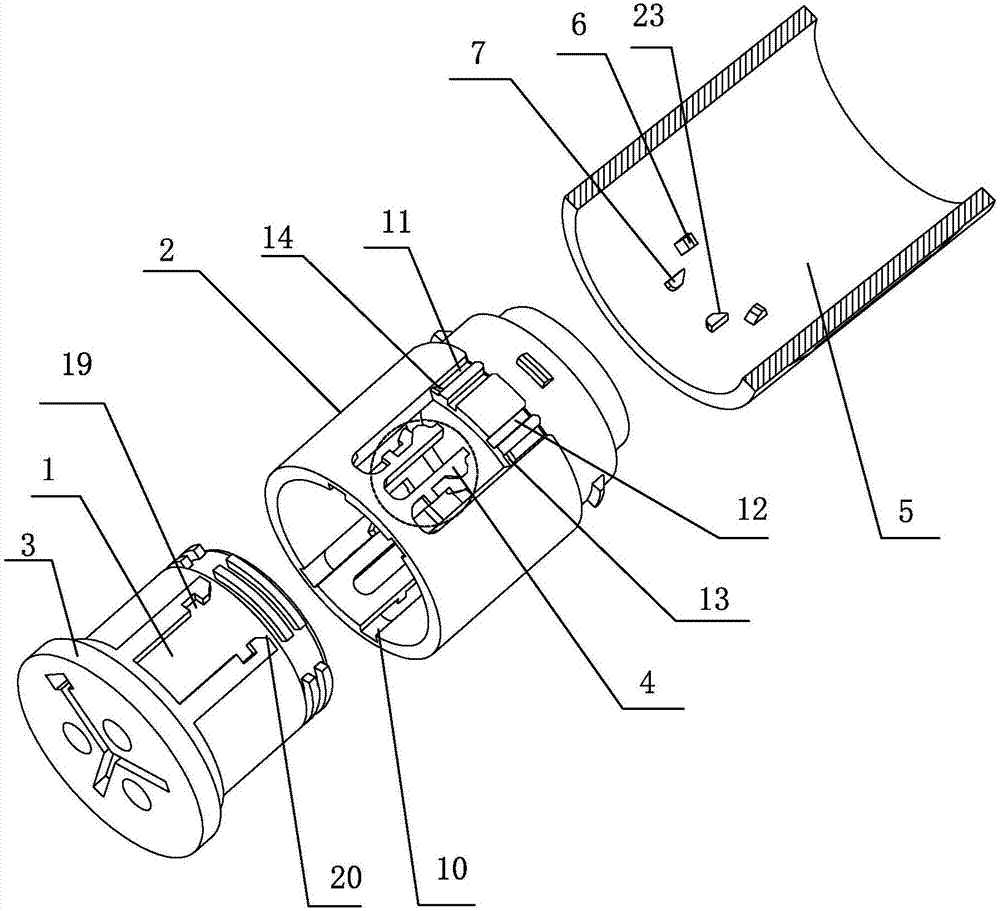

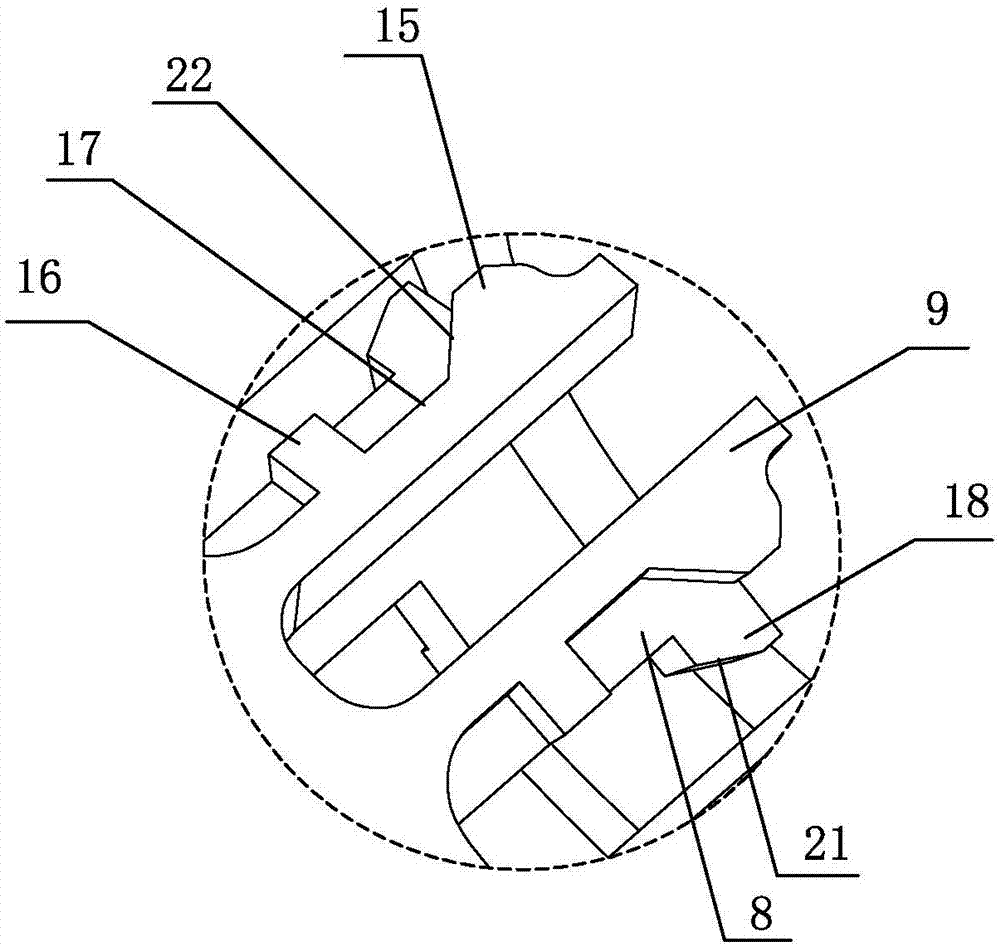

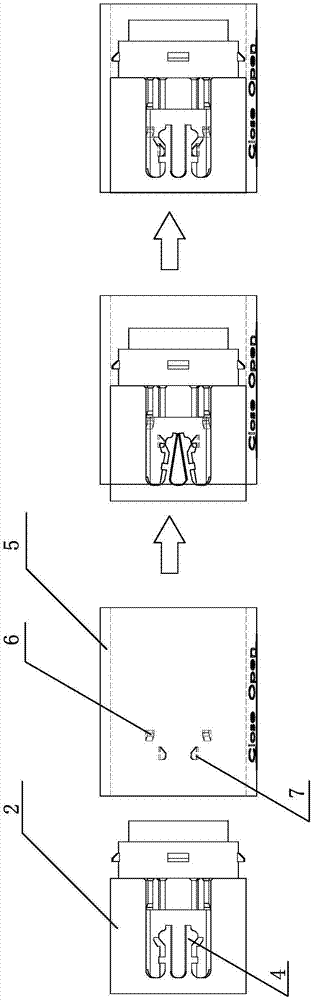

[0028] Embodiment one: see Figure 1~5 As shown, a locking structure for inter-plugging connectors, including a slot mechanism 1 arranged on the male or female rubber core, and an elastic buckle component set on the female rubber core 2 or the male rubber core 3 4, and the locking sleeve 5 sleeved outside the rubber core where the elastic buckle component 4 is located, the inner wall of the locking sleeve 5 is provided with a snap-fit connection with the rubber core where the elastic buckle component 4 is located A pair of anti-falling ribs 6, and a pair of pushing bosses 7 that cooperate with the elastic buckle assembly 4, the elastic buckle assembly 4 is a high and low double-layer U-shaped shrapnel, and the low-level shrapnel 8 is connected to the buckle The groove mechanism 1 is snap fit, and the high-level shrapnel 9 is snap fit with the pushing boss 7 .

[0029] Such as figure 1 As shown, the inner wall of the rubber core where the elastic buckle component 4 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com