High-pitch loudspeaker with improved glottal catch mounting structure

一种安装结构、扬声器的技术,应用在扬声器外壳支架、扩音器、传声器等方向,能够解决达不到间隙范围要求、SPL曲线波动、装配人员要求高等问题,达到保证高度稳定性、SPL曲线平滑、保证精密性和稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

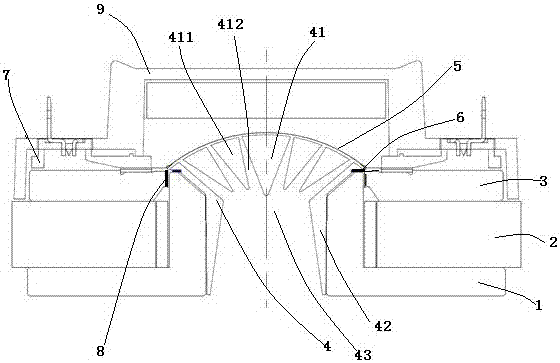

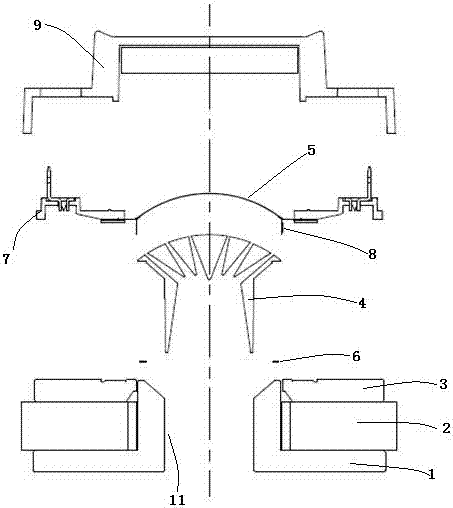

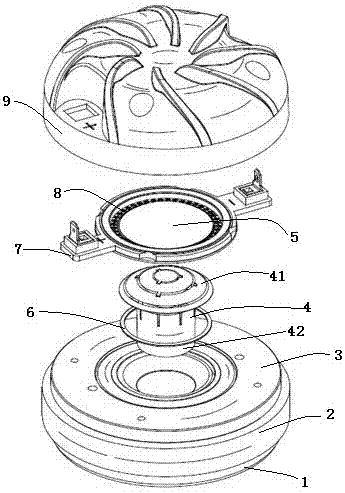

[0031] Figure 1~Figure 3 The cross-sectional view, cross-sectional exploded view and exploded view of the tweeter with the improved throat plug installation structure of this embodiment are respectively given, combined with reference Figure 1~Figure 3 , a tweeter with an improved throat plug installation structure, including a T iron 1, a magnet 2, a washer 3, a throat plug 4, a diaphragm 5, a soft gasket 6, a bracket 7, a voice coil 8 and a top cover 9. Among them, the voice coil 8 is located outside the T iron, the diaphragm 5 is connected and fixed to the bracket 7 , the top cover 9 contains the bracket 7 and the Washer 3 inside; the magnet 2 is located between the T iron 1 and the Washer 3 . In the structure of the T iron 1, the T iron 1 is provided with a central hole 11, the throat plug 4 is inserted into the central hole 11 and fixedly connected to the T iron 1, and a soft gasket is provided at the plane connection between the throat plug 4 and the T iron 1 6. The di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com